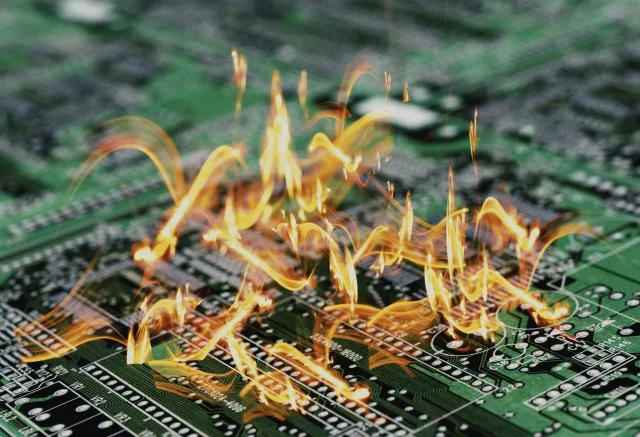

What Is a Burn-in PCB?

A Burn-in PCB is a specialized printed circuit board designed for stress testing and reliability verification of electronic components and assemblies. During burn-in testing, components are subjected to elevated temperatures, voltage, or current to identify early-life failures and ensure long-term reliability.

Unlike standard PCBs, Burn-in PCBs must withstand high thermal stress, high current density, and repeated cycles without performance degradation, making material selection and design crucial.

Key Design Requirements for Burn-in PCB

Designing an effective Burn-in PCB requires careful attention to several factors:

-

Thermal management

Copper planes, thick copper layers, and metal-core substrates help dissipate heat efficiently. -

High-current handling capability

Traces and vias must support the required current during testing without overheating. -

Mechanical durability

Boards must endure repeated insertion into burn-in fixtures. -

Stable electrical performance

Minimal impedance variations under high temperature and current conditions. -

Test point accessibility

Ensures easy connection to test equipment and monitoring systems.

Proper design ensures that Burn-in PCBs deliver consistent stress testing results.

Materials Used in Burn-in PCB

Burn-in PCBs often require specialized materials to handle high thermal and electrical stress:

-

FR-4 high-temperature laminates

Suitable for moderate burn-in conditions. -

Metal-core PCBs (MCPCB)

Excellent for heat dissipation in high-power applications. -

Ceramic PCBs

High thermal stability and low expansion for precision testing. -

High-reliability laminates

Ensures performance over repeated thermal cycles.

Material choice directly impacts board reliability and test accuracy.

Burn-in PCB Manufacturing Considerations

Burn-in PCB manufacturing requires strict quality and process control:

-

Thick copper plating and robust vias

To handle high current and thermal stress. -

Precise layer alignment and lamination

Prevents warpage under repeated thermal cycles. -

High-quality surface finish

ENIG, hard gold, or immersion silver for reliable connections. -

Electrical and thermal testing

Ensures boards meet burn-in requirements before shipment.

Experienced manufacturers ensure Burn-in PCBs maintain performance throughout testing.

Advantages of Burn-in PCB

Using a Burn-in PCB provides multiple benefits:

-

Detect early-life failures in components before mass production.

-

Verify product reliability under stress conditions.

-

Reduce warranty costs by ensuring only robust products are shipped.

-

Provide repeatable and controlled test conditions for high-volume electronics.

Burn-in PCBs are an essential part of quality assurance in electronics manufacturing.

Applications of Burn-in PCB

Burn-in PCBs are widely used in industries requiring high reliability:

-

Semiconductor burn-in testing

For ICs, microcontrollers, and memory devices. -

LED and display modules

Thermal cycling to verify longevity. -

Power electronics and automotive modules

High-current stress testing. -

Medical electronics

Ensures device reliability under continuous operation. -

Telecommunication and networking equipment

Detects early failures in mission-critical systems.

Burn-in PCBs ensure products meet strict reliability and performance standards.

Conclusion

A Burn-in PCB is a specialized tool for performing accelerated stress testing to ensure the reliability and durability of electronic components and assemblies. From thermal management and high-current design to robust materials and precise manufacturing, every aspect is critical to achieving consistent results.

Partnering with an experienced Burn-in PCB manufacturer ensures high-quality boards capable of withstanding demanding test conditions, reducing failures, and enhancing product reliability.