BT Epoxy PCB: A High-Performance Substrate for Advanced Electronics

As electronic products continue to evolve toward higher speed, smaller size, and higher reliability, the demand for advanced PCB materials is growing rapidly. Among various high-performance substrate materials, BT Epoxy PCB has become a preferred solution for many semiconductor and high-density applications due to its excellent thermal stability, electrical performance, and moisture resistance.

In this article, we will explain what BT Epoxy PCB is, its key characteristics, typical applications, and why it is widely used in modern electronics manufacturing.

What Is a BT Epoxy PCB?

BT Epoxy PCB refers to a printed circuit board made from BT resin (Bismaleimide Triazine resin) combined with epoxy-based materials. BT resin is a high-performance thermosetting polymer that offers enhanced heat resistance and mechanical strength compared to conventional FR4 materials.

BT Epoxy PCBs are commonly used in applications where higher thermal stability and better reliability are required, such as IC packaging substrates, BGA packages, and high-density interconnection (HDI) boards.

Key Benefits of BT Epoxy PCB

1. High Thermal Resistance (High Tg)

One of the most important advantages of BT Epoxy PCB is its high glass transition temperature (Tg). This makes it suitable for products that undergo multiple soldering processes or operate in high-temperature environments.

Why it matters:

Higher Tg means improved dimensional stability and reduced risk of warpage or delamination during assembly.

2. Low Moisture Absorption

BT epoxy materials typically offer lower moisture absorption compared to standard FR4. This property helps prevent moisture-related issues such as:

-

Popcorning during reflow soldering

-

Delamination

-

Electrical leakage in humid environments

Result: improved long-term reliability in harsh conditions.

3. Excellent Electrical Performance

BT Epoxy PCB materials provide stable dielectric properties, making them suitable for high-frequency and high-speed applications where signal integrity is critical.

This is especially valuable in:

-

Semiconductor packaging

-

High-speed data transmission

-

Compact consumer electronics

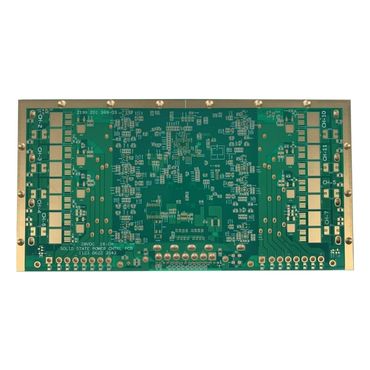

4. Better Mechanical Strength and Reliability

BT Epoxy PCBs offer good mechanical performance and stability, helping reduce cracking and deformation risks in fine-pitch, high-density designs.

They are widely chosen when products require:

-

High layer counts

-

Fine trace/space

-

High assembly reliability

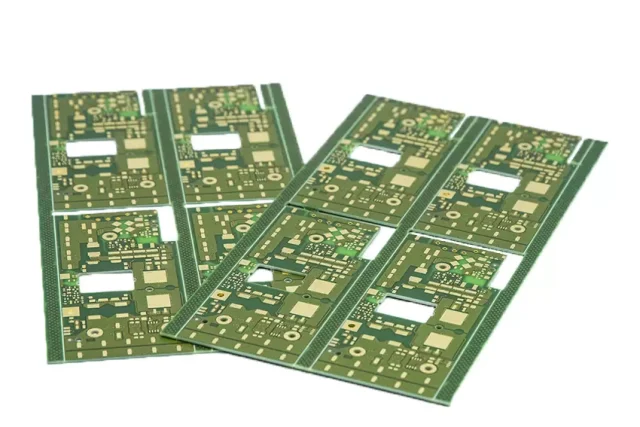

Common Applications of BT Epoxy PCB

BT Epoxy PCB is widely used in advanced electronics where reliability and performance are essential.

IC Packaging Substrates

BT epoxy substrates are commonly used in:

-

BGA (Ball Grid Array) packages

-

CSP (Chip Scale Packages)

-

Multi-chip modules

Because BT resin supports high-density routing and stable performance, it is ideal for semiconductor packaging.

High-Density Consumer Electronics

BT Epoxy PCBs are also found in compact devices requiring high reliability, such as:

-

Smartphones and wearable devices

-

High-end cameras

-

Compact IoT modules

Automotive and Industrial Electronics

For electronics exposed to temperature cycling and demanding environments, BT Epoxy PCB helps ensure stable performance in:

-

Automotive control systems

-

Industrial sensors and controllers

-

Communication equipment

BT Epoxy PCB vs FR4: What’s the Difference?

While FR4 remains the most commonly used PCB material, BT Epoxy PCB is designed for more demanding applications.

| Feature | FR4 PCB | BT Epoxy PCB |

|---|---|---|

| Thermal Resistance | Standard | Higher |

| Moisture Absorption | Higher | Lower |

| Electrical Stability | Good | Better |

| Suitable for IC Substrates | Limited | Excellent |

| Cost | Lower | Higher |

Conclusion:

If your project requires high thermal reliability, better moisture performance, or IC packaging compatibility, BT Epoxy PCB is a stronger option.

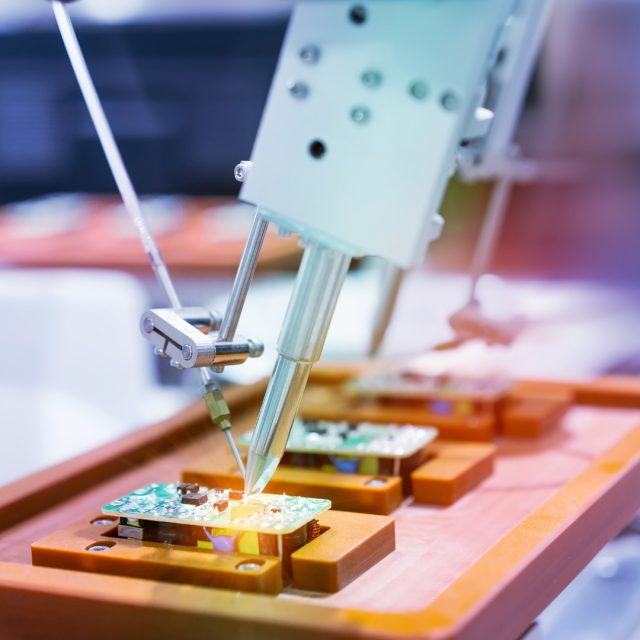

Manufacturing Considerations for BT Epoxy PCB

To ensure stable performance and high yield, BT Epoxy PCB production requires strict process control, especially for advanced designs.

Key manufacturing factors include:

-

Material handling and storage (moisture control)

-

Lamination parameters (pressure and temperature stability)

-

Drilling and via quality (microvias and fine holes)

-

Surface finish selection (ENIG, OSP, etc.)

-

Warpage control for thin and high-layer boards

Working with an experienced manufacturer helps reduce risks and improve consistency.

How to Choose the Right BT Epoxy PCB Supplier

When selecting a supplier for BT Epoxy PCB, it’s recommended to evaluate:

-

Material traceability and certification

-

Capability for fine line/space and HDI processes

-

Quality inspection methods (AOI, X-ray, impedance testing)

-

Engineering support for DFM review

-

Experience in IC substrate and package-related projects

A reliable supplier can provide stable quality and shorten development cycles.

Conclusion

BT Epoxy PCB is a high-performance solution designed for advanced electronics, especially in semiconductor packaging and high-density applications. With advantages such as high Tg, low moisture absorption, strong electrical stability, and reliable mechanical performance, BT epoxy materials help improve product reliability and manufacturing success.

If your project requires high reliability under thermal stress, high-density routing, or packaging-level performance, BT Epoxy PCB is an excellent material choice.