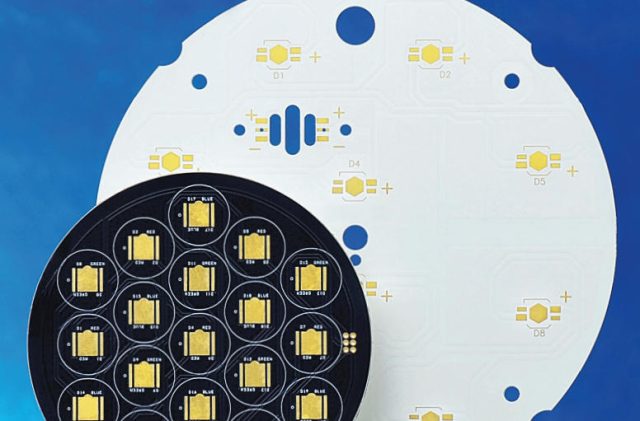

Bergquist introduces HPL-03015, a high-performance dielectric material within its Thermal Clad™ Metal Core PCB (MCPCB) line, specifically designed for high power LED applications. This material delivers outstanding thermal management, low thermal impedance, and superior durability, making it ideal for demanding LED designs in automotive, backlighting, and high-density lighting applications.

Key Features

-

Ultra-Low Thermal Impedance: HPL-03015 provides a thermal conductivity of 0.30°C/W, significantly reducing heat buildup in high-power LED circuits.

-

High Glass Transition Temperature (Tg): With a Tg of 185°C, the material maintains stability under elevated operating temperatures.

-

Thin Dielectric: At only 0.0015″ (38µm), it minimizes material thickness while maximizing thermal performance.

-

Durable and Reliable: Extends LED lifetime and improves performance in harsh thermal environments.

-

Cost-Effective Design: Reduces the need for additional LEDs and simplifies PCB layouts, lowering overall production complexity.

Applications

HPL-03015 is specifically formulated for applications requiring high watt-density and superior thermal management, including:

-

Backlighting: LED panels for displays and signage

-

Headlamps: Automotive and high-performance lighting

-

High Power LEDs: Indoor and outdoor lighting, street lamps, and architectural lighting

-

High-Density LED Arrays: Any PCB requiring efficient heat dissipation

Technical Data

| Property | Units | Typical Value |

|---|---|---|

| Dielectric Thickness | µm | 38 (0.0015″) |

| Glass Transition Temperature (Tg) | °C | 185 |

| Thermal Conductivity | °C/W | 0.30 |

| Thermal Performance | – | Excellent for high watt-density LEDs |

| Material Type | – | Thermal Clad Dielectric |

HPL-03015 ensures minimal thermal impedance, allowing heat to transfer efficiently to the metal core and maintain lower LED operating temperatures, which improves LED efficiency, lifespan, and overall system reliability.

Advantages of Bergquist Thermal Clad

-

Superior Heat Dissipation: Ensures even heat spread across high-power LED arrays, avoiding hot spots.

-

Reduced Component Stress: Maintains PCB and component integrity even under continuous high-power operation.

-

Simplified Design: By minimizing thermal issues, fewer LEDs and complex thermal solutions are required.

-

Enhanced Durability: Excellent mechanical and thermal reliability for automotive and industrial lighting applications.

Why Choose HPL-03015 for Your LED Projects

Using Bergquist HPL-03015 Thermal Clad in your MCPCB designs provides a cost-effective, high-performance solution for challenging thermal environments. Its thin profile, high Tg, and low thermal impedance make it the go-to material for high-density, high-power lighting applications, ensuring long-lasting, reliable LED performance.