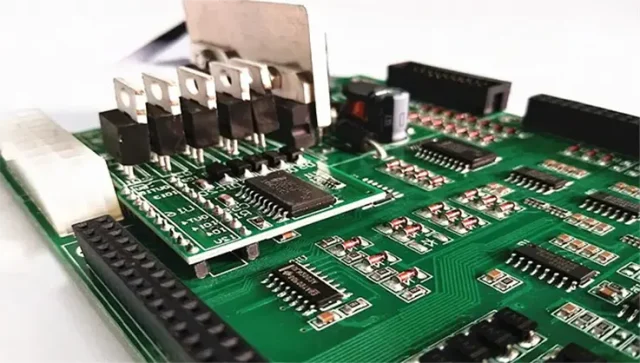

An Automotive IC Test PCB is a specialized semiconductor test PCB designed to validate automotive-grade integrated circuits used in ADAS, infotainment, powertrain, EV, and safety-critical systems. Automotive ICs require extreme reliability, stable electrical performance, and high-temperature tolerance, making their test PCBs critical for precise validation and quality assurance.

These boards interface between Automated Test Equipment (ATE) and the ICs, providing stable signal connections, accurate power delivery, and robust mechanical support under repeated test cycles.

Key Design Considerations for Automotive IC Test PCBs

1. High Pin Count and HDI Routing

Automotive ICs often come in BGA, QFN, QFP, or LGA packages with high pin counts, necessitating HDI technology, multilayer routing, microvias, and fine-line traces for reliable electrical access.

2. Controlled Impedance and Signal Integrity

High-speed and safety-critical signals require controlled impedance traces, matched signal lengths, and proper grounding to ensure accurate measurement and prevent crosstalk or signal degradation.

3. Thermal Stability

Automotive test environments may involve elevated temperatures to simulate real-world operating conditions. PCB materials with high Tg and low CTE ensure mechanical and electrical stability during thermal stress.

4. Robust Power Distribution Network (PDN)

Stable voltage supply and minimal noise are crucial for automotive IC testing. Optimized PDN design, low-impedance planes, and effective decoupling help maintain consistent test conditions.

5. Mechanical Precision

Consistent socket and probe contact is essential for repeatable test results. Automotive IC test boards are designed with tight tolerances, flatness control, and reinforced structures to withstand repeated ATE cycles.

Applications of Automotive IC Test PCBs

Automotive IC test PCBs are widely used in:

-

ADAS and autonomous driving system IC testing

-

Electric vehicle power management and battery IC validation

-

Infotainment and multimedia IC testing

-

Safety-critical MCU and logic IC validation

-

Sensor interface and mixed-signal automotive IC testing

These applications demand high reliability, signal integrity, and repeatable testing to meet automotive standards.

Manufacturing Requirements for Automotive IC Test PCBs

High-quality automotive IC test PCBs require:

-

Multilayer and HDI PCB fabrication

-

Fine-line etching and microvia processing

-

Controlled impedance verification

-

Thermal-resistant laminates and high Tg materials

-

Support for prototype, small batch, and volume production

Strict manufacturing controls ensure consistent electrical performance, mechanical reliability, and long-term durability.

Why Automotive IC Test PCB Quality Matters

Low-quality test boards can lead to:

-

Inconsistent measurements and false test failures

-

Signal degradation and crosstalk issues

-

Reduced test yield and longer validation cycles

-

Higher production costs and potential field failures

High-quality Automotive IC Test PCBs guarantee accurate testing, reliable performance, and compliance with automotive standards.

Conclusion

The Automotive IC Test PCB is a critical component for validating automotive-grade ICs under rigorous conditions. With high pin count support, controlled impedance, HDI routing, thermal stability, and mechanical precision, these boards ensure reliable, repeatable, and high-accuracy testing for automotive electronics.

Partnering with an experienced automotive IC test PCB manufacturer ensures faster validation, higher test yield, and long-term reliability for automotive semiconductor applications.