What Is an Automotive IC Test PCB?

An Automotive IC Test PCB is a specialized printed circuit board used to test automotive-grade integrated circuits during development, validation, and mass production. It connects the automotive IC under test (DUT) to automated test equipment (ATE), enabling precise electrical, functional, and reliability testing.

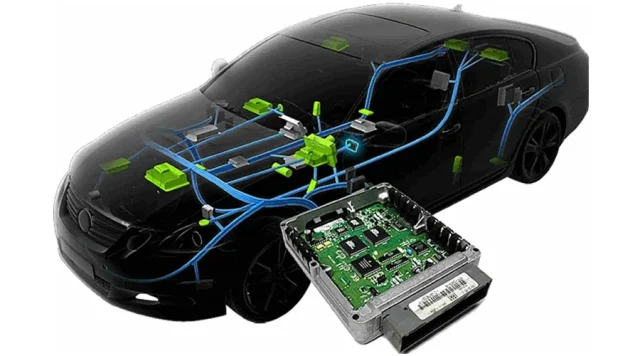

These PCBs are widely used for testing ICs deployed in ADAS, powertrain, body electronics, infotainment, battery management systems (BMS), and autonomous driving platforms.

Why Automotive IC Testing Requires Specialized PCBs

Automotive electronics operate in harsh environments and must meet strict safety and reliability standards. Compared with consumer IC testing, automotive IC testing involves:

-

Wide operating temperature ranges

-

Long product lifecycles

-

High reliability and low failure tolerance

-

Compliance with automotive quality standards

-

Repeated test cycles over extended periods

As a result, automotive IC test PCBs must be designed and manufactured to significantly higher standards.

Key Requirements of Automotive IC Test PCBs

A high-quality automotive IC test PCB typically requires:

-

Excellent signal integrity for digital, analog, and mixed-signal ICs

-

Controlled impedance routing for high-speed and communication interfaces

-

Stable power distribution for accurate functional testing

-

Thermal stability under elevated and cycling temperatures

-

High mechanical durability for repeated insertions and test cycles

Any PCB instability may lead to inaccurate test results or false failures.

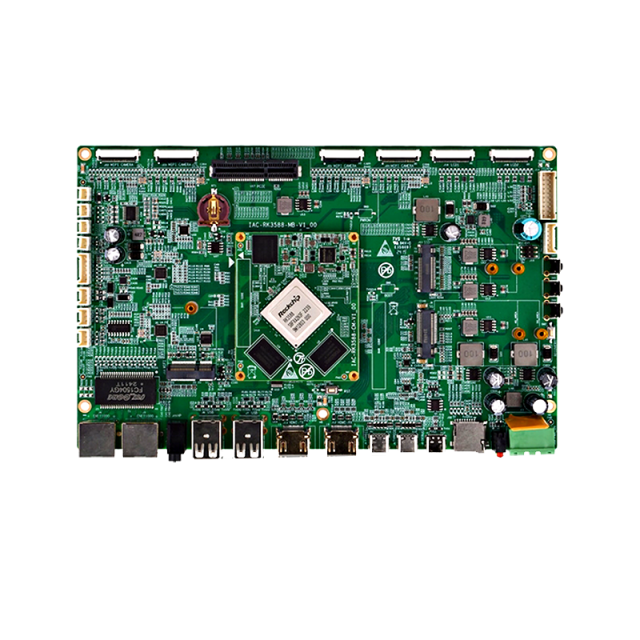

Design Considerations for Automotive IC Test Boards

Automotive IC test PCB design often includes:

-

Multilayer stackups with solid reference planes

-

Careful separation of analog, digital, and power domains

-

Short, impedance-matched signal paths

-

Robust grounding and shielding strategies

-

Optimized via structures to reduce parasitic effects

Designs must support both electrical accuracy and long-term reliability.

Materials Used in Automotive IC Test PCBs

Material selection plays a critical role in performance and durability. Common choices include:

-

High-Tg FR-4 for thermal stability

-

Low-loss materials for high-speed interfaces

-

Hybrid stackups for mixed-signal applications

-

Automotive-grade laminates with stable dielectric properties

The goal is to ensure consistent performance across temperature and lifecycle stress.

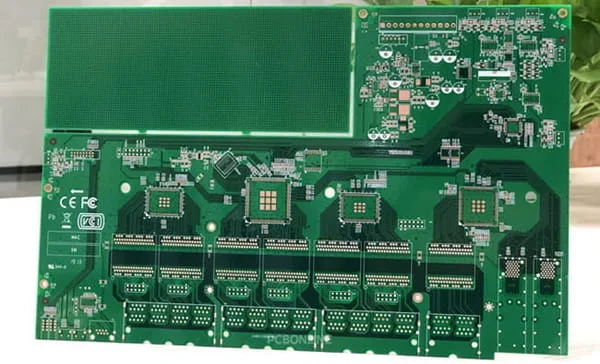

Manufacturing Capabilities for Automotive IC Test PCBs

Automotive IC test PCBs require advanced manufacturing processes, including:

-

Multilayer PCB fabrication

-

Tight impedance control and verification

-

High layer alignment accuracy

-

HDI technology for fine-pitch automotive ICs

-

Automotive-grade surface finishes such as ENIG or ENEPIG

Manufacturing consistency is essential for repeatable test results.

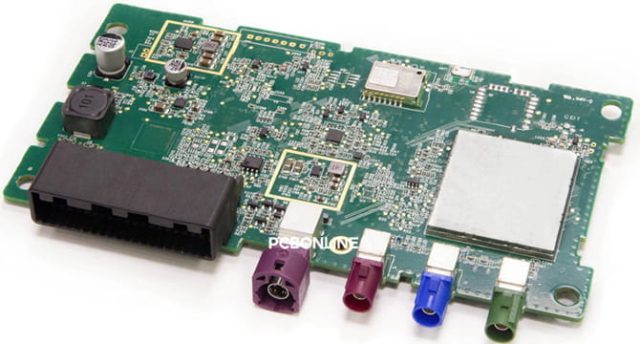

Assembly and Test Interface Integration

Assembly for automotive IC test PCBs may involve:

-

Automotive IC test sockets

-

High pin count DUT interfaces

-

Precision passive components

-

Robust soldering processes for durability

Assembly quality directly affects test repeatability and contact reliability.

Applications of Automotive IC Test PCBs

Automotive IC test PCBs are used across a wide range of vehicle electronics, including:

-

ADAS and autonomous driving ICs

-

Power management and motor control ICs

-

Battery management system (BMS) ICs

-

In-vehicle networking ICs (CAN, LIN, FlexRay, Ethernet)

-

Infotainment and cockpit electronics

They support testing throughout IC development, qualification, and mass production.

Why Choose a Professional Automotive IC Test PCB Manufacturer

An experienced automotive test PCB manufacturer offers:

-

Deep understanding of automotive testing requirements

-

Proven reliability-focused PCB designs

-

Stable quality for long-term production testing

-

Fast prototype and small batch support

-

Engineering assistance from design to assembly

The right manufacturing partner helps reduce test risk and ensures compliance with automotive industry expectations.