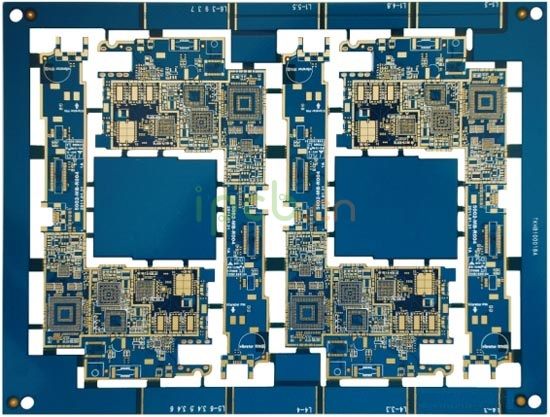

In automated test equipment development, early-stage validation determines long-term system reliability. The ATE PCB Prototype provides a controlled platform for verifying electrical performance, mechanical interfaces, and test repeatability before production deployment.

A well-designed ATE PCB prototype reduces risk and accelerates development cycles.

Role of ATE PCB Prototypes in Test Engineering

An ATE PCB Prototype bridges conceptual design and production-ready test systems. It allows engineers to:

-

Validate test architecture under real conditions

-

Verify signal and power behavior early

-

Identify design limitations before scale-up

This stage is critical for cost and time efficiency.

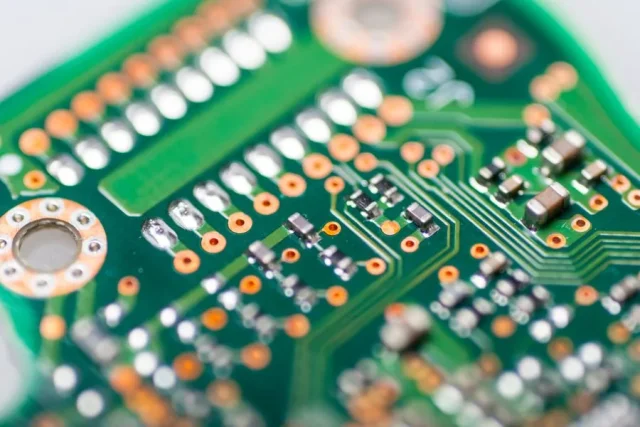

Signal Integrity Evaluation at the Prototype Stage

High-speed test environments require precise signal behavior. ATE PCB prototypes focus on:

-

Controlled impedance routing

-

Simplified and accessible signal paths

-

Accurate reference plane structures

Early signal integrity validation prevents later redesigns.

Power Integrity and Stability Testing

Power delivery must remain stable under dynamic test loads. ATE PCB prototypes enable:

-

Evaluation of decoupling strategies

-

Observation of transient power noise

-

Optimization of ground structures

These insights improve long-term test reliability.

Design Flexibility for Rapid Iteration

ATE PCB prototypes are designed to support:

-

Layout modifications and design refinements

-

Multiple revision cycles

-

Engineering debug access

Flexibility speeds up test system optimization.

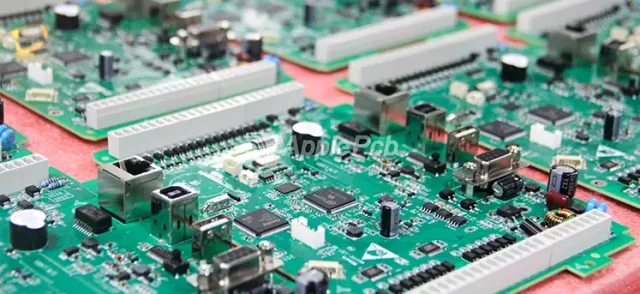

Mechanical and Interface Verification

Prototype ATE PCBs allow engineers to:

-

Verify connector and socket alignment

-

Test mechanical fit with ATE fixtures

-

Identify handling and assembly challenges

Mechanical validation is essential before production.

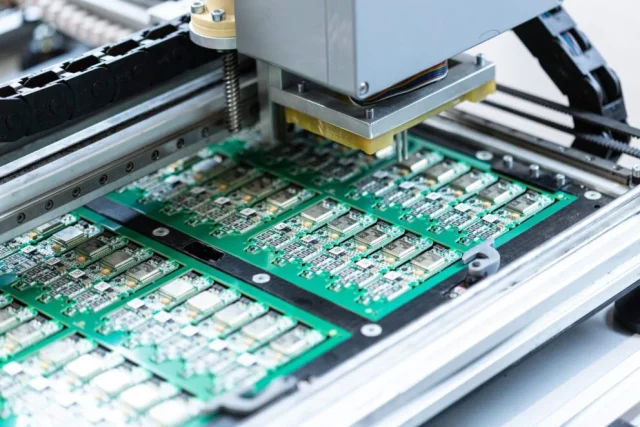

Manufacturing Speed and Engineering Support

Fast turnaround is a key requirement. ATE PCB prototype manufacturing emphasizes:

-

Quick fabrication and assembly

-

Engineering feedback and DFM review

-

Small-batch production capability

Speed enables faster test validation.

Typical Applications of ATE PCB Prototypes

ATE PCB prototypes are commonly used in:

-

Semiconductor device characterization

-

Engineering validation testing

-

New ATE platform development

-

Pre-production test evaluation

Each application benefits from rapid iteration.

Selecting an ATE PCB Prototype Partner

When choosing an ATE PCB prototype manufacturer, consider:

-

Experience with test and semiconductor PCBs

-

Controlled impedance and multilayer capability

-

Fast turnaround and engineering support

-

Smooth transition from prototype to production

The right partner supports long-term success.

Conclusion

The ATE PCB Prototype is a critical enabler of accurate and reliable automated test systems. By supporting fast validation, efficient debugging, and informed design decisions, ATE PCB prototypes help engineers deliver robust and production-ready test platforms.

Partnering with an experienced ATE PCB prototype supplier ensures reduced development risk and faster time to market.