Aluminum Nitride PCB: The Premium Ceramic Substrate for Advanced Thermal Management

As modern electronics continue to push toward higher power density, smaller size, and higher reliability, thermal management becomes a key design challenge. In applications such as power modules, EV systems, high-brightness LEDs, and industrial converters, standard PCB materials often struggle to dissipate heat effectively.

That’s why Aluminum Nitride PCB (AlN PCB) is widely recognized as one of the best solutions for high-performance thermal management. With excellent thermal conductivity, strong electrical insulation, and high-temperature stability, AlN substrates are commonly used in demanding power and high-reliability electronic systems.

In this article, we’ll explain what Aluminum Nitride PCB is, its key benefits, typical applications, and important manufacturing considerations.

What Is an Aluminum Nitride PCB?

An Aluminum Nitride PCB is a type of ceramic PCB that uses Aluminum Nitride (AlN) as the base substrate material. AlN is known for its outstanding ability to transfer heat while maintaining excellent electrical insulation.

Compared with traditional materials such as FR4 or aluminum-based PCBs (IMS), AlN PCBs offer:

-

Much higher thermal conductivity

-

Better high-temperature stability

-

Strong insulation for high-voltage designs

-

High reliability for long-term operation

Because of these advantages, AlN PCB is often used in high-end power and thermal-critical electronics.

Key Benefits of Aluminum Nitride PCB

1. Outstanding Thermal Conductivity

The biggest advantage of Aluminum Nitride PCB is its excellent heat dissipation performance, making it ideal for high-power devices.

This helps:

-

Reduce junction temperature

-

Improve system efficiency

-

Prevent thermal failure

-

Extend product lifespan

For power modules and LED applications, effective heat transfer directly improves reliability and performance.

2. Excellent Electrical Insulation

Even with high thermal conductivity, AlN ceramic remains a strong electrical insulator. This makes it suitable for:

-

High-voltage power modules

-

Isolation requirements in converters

-

High-reliability industrial power systems

This combination of insulation + heat transfer is one of the key reasons AlN is preferred in power electronics.

3. High Temperature Resistance and Stability

AlN PCB can maintain stable performance under high operating temperatures and thermal cycling conditions. It is suitable for environments involving:

-

Continuous high-power operation

-

Harsh industrial conditions

-

Automotive temperature cycling

This improves long-term stability and reduces risks such as warpage or material degradation.

4. High Reliability for Power and Automotive Electronics

Aluminum Nitride PCBs are commonly used in products requiring high reliability, such as:

-

EV power control systems

-

Automotive inverters

-

Industrial motor drives

The material supports stable performance even under vibration, temperature cycling, and long service life requirements.

Common Types of Aluminum Nitride PCB

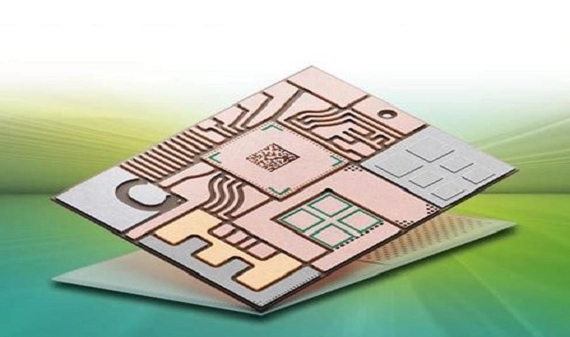

DBC Aluminum Nitride PCB (Direct Bonded Copper)

DBC AlN PCB bonds copper directly onto the AlN ceramic substrate. It provides:

-

Excellent thermal transfer

-

High current carrying capability

-

Strong reliability for power modules

This type is widely used in IGBT and MOSFET power modules.

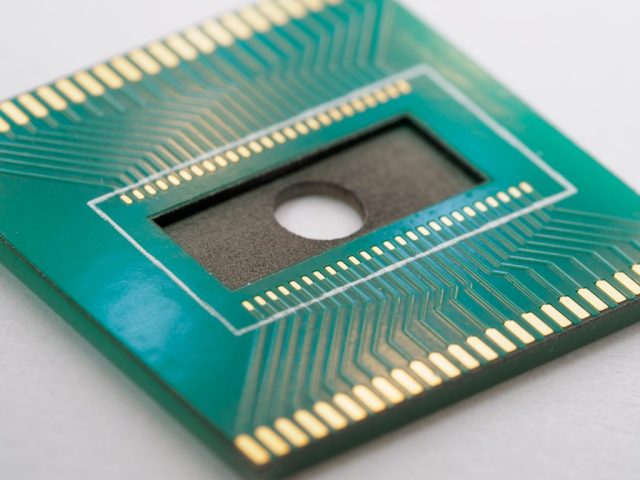

AMB Aluminum Nitride PCB (Active Metal Brazing)

AMB technology uses brazing to bond copper to AlN ceramic, offering:

-

Strong bonding strength

-

Better thermal cycling performance

-

High reliability in demanding environments

AMB AlN PCBs are commonly used in automotive and industrial high-reliability applications.

Typical Applications of Aluminum Nitride PCB

Power Modules (IGBT / MOSFET)

AlN PCB is widely used for:

-

IGBT modules

-

MOSFET power stages

-

Power converters and inverters

It supports high power density designs with improved thermal performance.

High-Brightness LED Modules

For LED systems, AlN PCB helps:

-

Maintain stable brightness

-

Reduce thermal degradation

-

Extend LED lifetime

It is commonly used in automotive lighting and industrial high-power LED solutions.

Automotive Electronics and EV Systems

AlN PCB is used in:

-

EV inverters

-

On-board chargers (OBC)

-

DC-DC converters

-

Motor control systems

These systems require excellent thermal performance and high reliability.

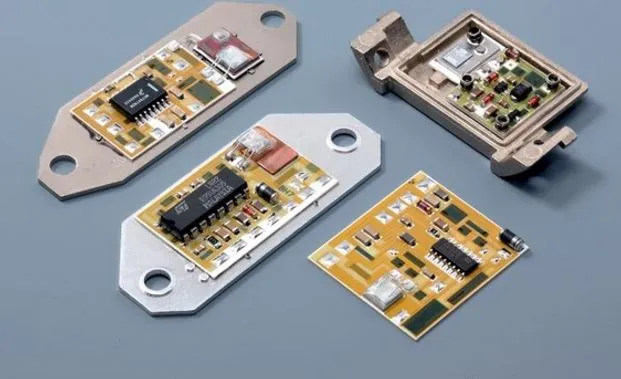

Industrial and High-Reliability Electronics

AlN PCB is also applied in:

-

Industrial power supplies

-

High-voltage modules

-

High-temperature sensor systems

Aluminum Nitride PCB vs Alumina PCB (Al₂O₃)

Both are ceramic PCB materials, but AlN is often selected for higher thermal demands.

| Feature | Alumina PCB (Al₂O₃) | Aluminum Nitride PCB (AlN) |

|---|---|---|

| Thermal Conductivity | Medium | Higher |

| Cost | Lower | Higher |

| Thermal Management | Good | Excellent |

| Typical Use | General ceramic PCB | High power / high-end thermal |

If your application is highly thermal-critical, Aluminum Nitride PCB is typically the better choice.

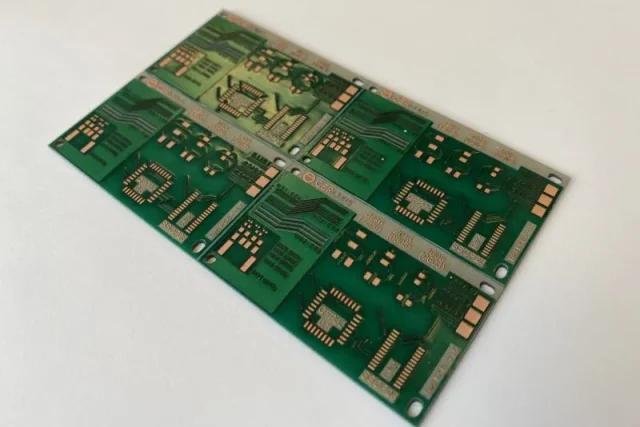

Manufacturing Considerations for Aluminum Nitride PCB

To ensure stable quality and reliability, AlN PCB production requires specialized processes and strict control, including:

-

Substrate quality and thickness control

-

Copper bonding method selection (DBC or AMB)

-

Copper thickness and pattern accuracy

-

Surface finish selection for solderability

-

Thermal cycling reliability testing

-

Inspection for cracks, delamination, and bonding strength

Working with an experienced ceramic PCB manufacturer helps reduce risk and ensures consistent performance.

Conclusion

Aluminum Nitride PCB (AlN PCB) is a premium ceramic substrate solution for high-performance electronics requiring excellent heat dissipation, strong insulation, and high-temperature reliability. It is widely used in power modules, EV systems, high-brightness LEDs, and industrial power electronics, enabling stable operation under demanding thermal conditions.

If your project requires advanced thermal management and long-term reliability, Aluminum Nitride PCB is an ideal material choice.