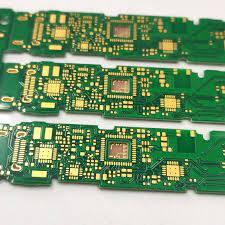

TLY-5 PCB materials have become a core enabler in modern high-frequency electronics, especially as RF, microwave, and mmWave systems continue pushing toward higher bandwidth, lower loss, and stricter phase-stability requirements. Built on a PTFE-based low-loss dielectric platform, TLY-5 PCBs deliver exceptionally high electrical performance while supporting the reliability demands of satellite payloads, radar front-ends, high-power amplifiers, phased-array antennas, and precision timing networks.

This article explores how TLY-5 PCB materials shape RF performance through dielectric stability, conductor-interface optimization, stackup engineering, thermal reliability, and system-level signal integrity.

1. Dielectric Stability and Its Impact on RF Wave Propagation

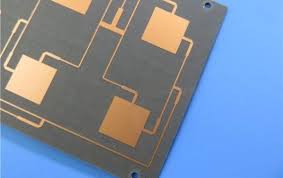

The most critical attribute of any high-frequency PCB laminate is its dielectric constant (Dk) and dissipation factor (Df). TLY-5 offers:

• Ultra-low Dk tolerance → enables predictable microstrip & CPW (coplanar waveguide) impedance

• Low Df at microwave/mmWave frequencies → minimizes dielectric loss over long trace lengths

• Stable Dk vs. frequency and temperature → essential for phase-coherent systems

In phased-array radar or satellite transceivers, even a minor Dk shift can produce significant phase error across antenna elements. TLY-5’s stability preserves waveform integrity, ensuring consistent propagation velocity and minimizing group-delay variation.

This directly improves beam-steering accuracy, link stability, and long-range resolution.

2. Conductor Loss Reduction and Copper Interface Engineering

TLY-5 PCB laminates can pair with low-profile copper (e.g., rolled or reverse-treated copper). This reduces conductor surface roughness, which is vital at mmWave frequencies where skin depth becomes extremely shallow.

Key mechanisms include:

• Reduced conduction loss → improves S21 insertion loss performance

• Lower reflection coefficients → boosts impedance precision

• Cleaner harmonics and spectral purity → essential for wideband radar and LO distribution

The copper–dielectric interface of TLY-5 supports both microstripline and grounded coplanar waveguide designs, delivering consistent RF performance even at 40–90 GHz routing.

3. Multi-Layer TLY-5 PCB Stackup Engineering for EMI/EMC Robustness

Systems integrating RF, digital control, and high-density power modules require stackups that protect RF channels from near-field coupling and broadband emissions. TLY-5 stackups enable:

• Precise dielectric thickness control → stable controlled-impedance routing

• Optimized ground referencing → essential for isolation in RF front-ends

• Via-shielding and fence-via structures → reduces surface waves and crosstalk

• Hybrid stackups with adjacent low-loss layers → supports high-power amplifiers and converters

The result is cleaner transmission paths, reduced EMI leakage, and higher SNR for sensitive RF receivers.

This is particularly important for:

• Ku/Ka-band satellite communication systems

• AESA radar modules

• GNSS timing boards

• 5G/6G mmWave transceiver hardware

4. Thermal Reliability and Mechanical Stability in Aerospace Environments

High-frequency PCBs deployed in satellites or high-altitude radar platforms face harsh thermal gradients and repeated cycling. TLY-5 exhibits:

• Low thermal expansion (when reinforced) → protects via integrity and solder joints

• Minimal moisture absorption → critical for vacuum or humidity-sensitive systems

• High radiation tolerance (PTFE base) → supports long-life orbiting hardware

The laminate maintains impedance and dielectric behavior even after extended thermal stress, guaranteeing stable RF performance over mission life.

5. System-Level Impact on RF Architecture and Performance

TLY-5 PCBs improve system-level metrics such as:

• Phase linearity across wide bandwidths → essential for radar chirps, FMCW systems, and phased arrays

• Noise floor reduction → improves receiver sensitivity

• Power efficiency in high-power RF chains → reduces thermal load

• Stable impedance for filters, couplers, and matching networks → boosts overall link efficiency

By integrating TLY-5 materials, RF engineers gain tighter design margins, more predictable simulations, and higher-performance RF modules from prototype to deployment.

Conclusion

TLY-5 PCB materials offer a high-performance platform optimized for modern RF and mmWave systems requiring ultra-low loss, stable dielectric behavior, and robust signal integrity. Their combination of dielectric precision, low conductor loss, EMI resistance, and aerospace-grade reliability makes them an indispensable choice for satellite communication, radar engineering, and high-frequency wireless architecture.

KKPCB provides advanced TLY-5 PCB fabrication with controlled impedance, low-profile copper, hybrid stackups, and high-frequency DFM engineering support—enabling superior performance across mission-critical RF systems.