Introduction to Aluminum Oxide (Al₂O₃) Ceramic PCBs

In the field of printed circuit board (PCB) manufacturing, the choice of substrate material plays an essential role in determining the product’s performance, reliability, and heat dissipation capability. Ceramic PCBs—particularly those using Aluminum Oxide (Al₂O₃)—have become increasingly popular due to their outstanding thermal and electrical properties.

This article explores the characteristics, benefits, manufacturing process, and industry applications of Al₂O₃ ceramic PCBs.

What Is an Alumina (Al₂O₃) Ceramic PCB?

An Alumina PCB, also known as an Al₂O₃ PCB, is a printed circuit board made from aluminum oxide ceramic material. It offers several significant advantages:

-

High thermal conductivity (15–50 W/m·K)

-

Low coefficient of thermal expansion (CTE)

-

Excellent electrical insulation

-

High mechanical strength

-

Superior purity levels leading to improved surface quality

Thanks to these properties, Al₂O₃ PCBs are widely used in LED modules, high-frequency devices, power electronics, automotive systems, aerospace equipment, and medical technologies.

Purity Levels of Alumina PCBs

Alumina ceramic substrates come in several purity levels, such as:

-

96%

-

99.5%

-

99.6% (highest grade)

Higher purity provides:

-

Enhanced appearance

-

Superior electrical performance

-

Reduced surface roughness

-

Improved mechanical consistency

These characteristics make high-purity Al₂O₃ suitable for demanding thin-film and high-frequency applications.

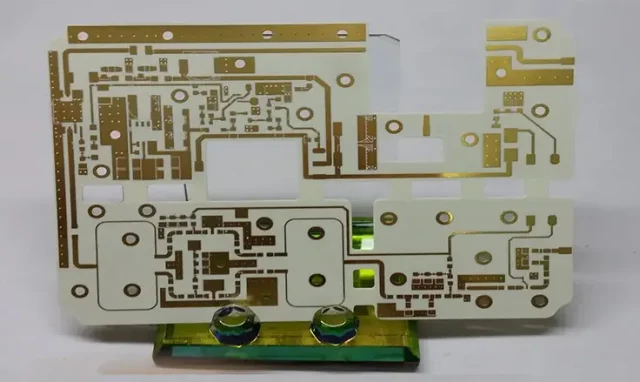

Types of Alumina Ceramic PCBs

1. 96% Alumina Substrate

This is the most commonly used grade for ceramic PCBs.

Key features:

-

Ideal for thick-film circuits and hybrid microelectronics

-

Excellent insulation and chemical resistance

-

Good thermal stability and dimensional consistency

-

Cost-effective for general-purpose ceramic PCB applications

2. 99.5% Alumina Substrate

A suitable choice for applications requiring smoother surfaces without extreme precision.

Advantages:

-

Finer grain structure

-

Achieves surface smoothness up to 2 micro-inches

-

Available in larger sizes and thicker formats

However, it has lower thermal conductivity and mechanical durability compared with the 99.6% grade.

3. 99.6% Alumina Substrate

The highest-purity alumina for precision applications.

Benefits:

-

Ultra-smooth surfaces (<1 micro-inch roughness)

-

Excellent dielectric strength

-

Superior corrosion and wear resistance

-

Ideal for sputtering, evaporation, and CVD thin-film processes

Why Choose Us?

JarnisTech provides world-class ceramic PCB solutions backed by:

-

No minimum order quantity (MOQ)

-

Over 10 years of ceramic PCB R&D and manufacturing experience

-

Global distribution to more than 40 countries

-

Professional support with responses within 24 hours

We ensure timely delivery, high-precision manufacturing, and industry-leading quality.

Manufacturing Process of Al₂O₃ Ceramic PCBs

Producing Al₂O₃ ceramic PCBs requires specialized equipment and strict quality control. The process includes:

1. Substrate Selection and Preparation

-

Choose appropriate thickness and size

-

Clean and pre-treat to remove contaminants

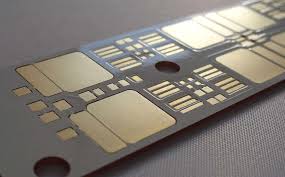

2. Screen Printing of Circuit Patterns

-

Conductive pastes containing gold, silver, or copper are printed through a fine mesh

-

Precise layout formation ensures proper electrical performance

3. High-Temperature Sintering

-

Metal particles fuse under elevated temperatures

-

Creates robust, corrosion-resistant, long-lasting conductive paths

4. Surface Finishing

The most commonly used finish is ENIG (Electroless Nickel Immersion Gold).

Benefits:

-

Excellent solderability

-

High corrosion resistance

-

Reliable long-term performance

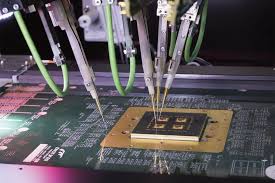

5. Final Quality Inspection

Includes:

-

Electrical testing

-

Adhesion checks

-

Visual and dimensional inspection

-

Surface integrity assessment

All products must meet strict industry standards before shipment.

Key Properties of Al₂O₃ Ceramic PCBs

-

High thermal conductivity (15–50 W/m·K)

-

High melting point (1400–1600°C depending on purity)

-

Outstanding electrical insulation

-

Strong mechanical performance

-

Low CTE (6–8 ppm/°C) to reduce thermal stress

-

Excellent chemical stability

These characteristics make alumina PCBs well-suited for harsh or high-power environments.

Importance of Alumina PCBs in Modern Electronics

Compared to FR4 and metal-core PCBs, alumina PCBs offer:

-

Much better thermal performance

-

Higher electrical insulation

-

Superior long-term reliability

-

No need for a dielectric layer

-

Lower thermal stress on solder joints

Although the cost is higher, its advantages make Al₂O₃ PCBs indispensable in advanced applications where performance and reliability are critical.

Common Applications of Alumina Ceramic PCBs

Alumina PCBs are widely used in:

Comparison with Other PCB Substrates

FR4 PCB

- Low cost and widely used

- Poor heat dissipation

- Not suitable for high-power electronics

Metal-Core PCB (MCPCB)

- Better heat dissipation than FR4

- Often used for medium-power LEDs

- Still lower performance than ceramic PCBs

Al₂O₃ Ceramic PCB

Highest thermal performance

Best electrical insulation

Most stable under high temperatures

Perfect for demanding and high-power applications

Lead Time & Pricing for Alumina PCBs

The price depends on:

Board size

Purity level

Design complexity

Quantity

Thickness and metallization process

Standard lead times:

FR4 & Aluminum PCBs: 5–7 days

Alumina Ceramic PCBs: 13–15 days

Expedited orders: as fast as 7 days

Gerber files are required for accurate quotation.

Future Trends of Alumina Ceramic PCBs

Higher integration and miniaturization

Advanced material blends (SiC, B₄C)

Functionalized ceramic surfaces for sensing or energy harvesting

3D printing of ceramic substrates

Environmentally friendly alternatives to traditional PCBs

These advancements will further expand the use of ceramic PCBs in next-generation electronics.

Final Thoughts

Aluminum Oxide (Al₂O₃) ceramic PCBs offer exceptional thermal conductivity, electrical insulation, and long-term reliability—qualities that make them essential for high-performance electronic systems. As demand for compact, powerful, and thermally stable devices continues to rise, alumina PCBs will play an increasingly significant role in the electronics industry.

If you are looking for high-precision ceramic PCB fabrication and assembly services, JarnisTech is ready to support your project with expert engineering and advanced manufacturing capabilities.