Introduction

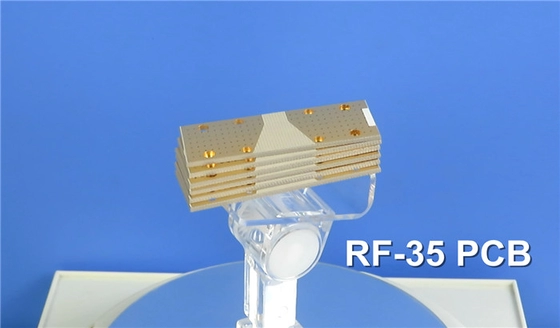

As electronic systems continue to evolve toward higher frequencies and faster data rates, the need for advanced laminate materials becomes increasingly critical. Among the top performers in RF and microwave PCB substrates, Taconic RF-35 has gained industry-wide recognition for its outstanding signal integrity, thermal stability, and material uniformity.

With a dielectric constant (Dk) of 3.5, a remarkably low loss tangent, and superior reliability, RF-35 provides engineers with the performance foundation required for next-generation wireless communication, radar, and high-speed digital applications.

What Is Taconic RF-35?

Taconic RF-35 is a high-frequency PTFE-based laminate reinforced with ceramic fillers, engineered specifically for radio frequency (RF) and microwave printed circuit boards (PCBs). The material’s design ensures exceptional electrical consistency and mechanical stability, outperforming traditional FR4 laminates in high-speed signal environments.

Core Material Properties

-

Dielectric Constant (Dk = 3.5 ± 0.05)

The tightly controlled dielectric constant enables precise impedance matching and consistent electrical performance across the PCB, ensuring minimal signal reflection and distortion. -

Loss Tangent (Df = 0.0019)

With extremely low energy dissipation, RF-35 minimizes insertion loss and enhances the quality factor (Q) of resonant circuits, supporting reliable signal propagation from DC to Ku-band frequencies. -

Moisture Absorption (≤ 0.02%)

RF-35’s low moisture absorption prevents degradation caused by humidity, ensuring long-term stability and reliability even in harsh environments. -

Thermal Performance (CTE = 82 ppm/°C, Tg > 280°C)

Excellent thermal stability and compatibility with lead-free soldering processes (up to 260°C) ensure reliable assembly and operation under demanding thermal conditions. - Thermal Conductivity (0.71 W/mK)

Enhanced heat dissipation prevents localized thermal buildup, improving both mechanical integrity and component reliability.

Taconic RF-35 vs FR4

| Property | Taconic RF-35 | FR4 |

|---|---|---|

| Dielectric Constant | 3.5 ± 0.05 | ~4.5 ± 0.25 |

| Loss Tangent | 0.0019 | 0.02 |

| Moisture Absorption | 0.02% | 0.2% |

| Frequency Range | Up to Ku Band | ≤ 5 GHz |

| Thermal Stability | High (Tg > 280°C) | Moderate |

| Signal Integrity | Excellent | Average |

Compared to FR4, Taconic RF-35 delivers tighter dielectric control, lower signal loss, and superior high-frequency performance. Its stable characteristics allow engineers to design microwave and mmWave circuits with minimal loss and maximum consistency.

Applications of Taconic RF-35

-

Wireless Communication Systems

Ideal for base stations, satellite links, and antennas where signal clarity and transmission efficiency are critical. -

Radar Systems

Used extensively in military, aerospace, and automotive radar systems that require high accuracy and minimal signal distortion. -

Microwave and mmWave Devices

Perfect for microwave filters, antennas, and millimeter-wave modules requiring ultra-low loss and stable impedance. -

High-Speed Digital Electronics

Supports data center servers, high-speed network switches, and storage systems by minimizing crosstalk and ensuring signal integrity. -

Automotive Electronics

Integral in ADAS, collision avoidance radar, and in-vehicle communication systems where safety and reliability are paramount. -

Aerospace and Defense

Trusted in avionics, satellite systems, and electronic warfare due to its moisture resistance and durability under extreme conditions.

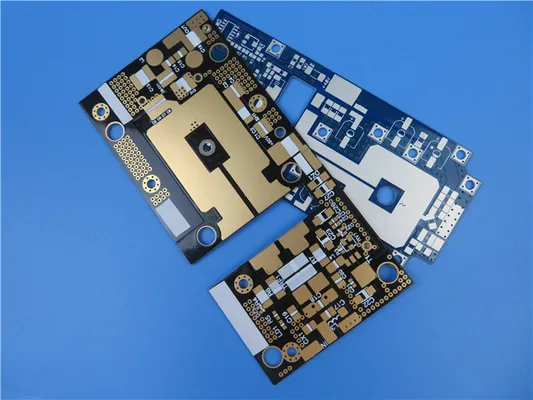

The Importance of RF-35 in PCB Fabrication

Taconic RF-35 plays a pivotal role in ensuring consistent signal integrity and thermal reliability during PCB fabrication. Its precise material tolerances allow for repeatable impedance control and high yield during multilayer production.

Manufacturers benefit from its stable process characteristics, enabling efficient drilling, plating, and lamination without compromising material integrity.

Key Design Considerations

-

Frequency Range and Signal Loss Control

-

Dielectric Constant Uniformity

-

Controlled Impedance Stack-up

-

Environmental Stability

-

Thermal Expansion and Lead-Free Compatibility

-

Compliance with IPC and ISO Standards

Engineers should evaluate these parameters to ensure that RF-35 laminates deliver optimal results across various RF and high-speed digital designs.

How to Choose a Reliable Taconic RF-35 PCB Manufacturer

Selecting an experienced PCB partner is crucial for maximizing RF-35’s potential. When evaluating suppliers, consider the following:

-

Proven expertise in RF/microwave PCB manufacturing

-

Strong portfolio of Taconic-based projects

-

Advanced impedance control and simulation tools

-

Certified quality management (ISO 9001)

-

Fast turnaround and rigorous testing protocols

-

Transparent communication and engineering support

A professional manufacturer like KKPCB integrates these capabilities to ensure your RF-35 PCBs perform consistently across design, prototyping, and mass production stages.

Conclusion

Taconic RF-35 represents a benchmark in high-frequency PCB materials, delivering precise dielectric properties, low loss, and reliable thermal performance. Its superior consistency across fabrication lots enables predictable, repeatable behavior—vital for advanced RF, microwave, and multi-gigabit applications.

For engineers pursuing maximum signal integrity and bandwidth optimization, RF-35 remains a cornerstone material for next-generation designs.