What Is a Burn-in Board PCB?

A Burn-in Board PCB is a specialized printed circuit board used in semiconductor reliability testing to identify early device failures. It connects packaged integrated circuits to burn-in test systems, allowing devices to operate under elevated temperature, voltage, and electrical stress conditions over extended periods.

Burn-in board PCBs play a critical role in ensuring long-term semiconductor reliability and are widely used in automotive electronics, aerospace, industrial control, and high-reliability communication systems.

Purpose of Burn-in Testing

Burn-in testing is designed to accelerate aging and detect early component failures before products are released to the market. A burn-in board PCB enables:

-

Continuous operation of ICs under stress conditions

-

Early failure screening and reliability verification

-

Electrical performance validation under thermal stress

-

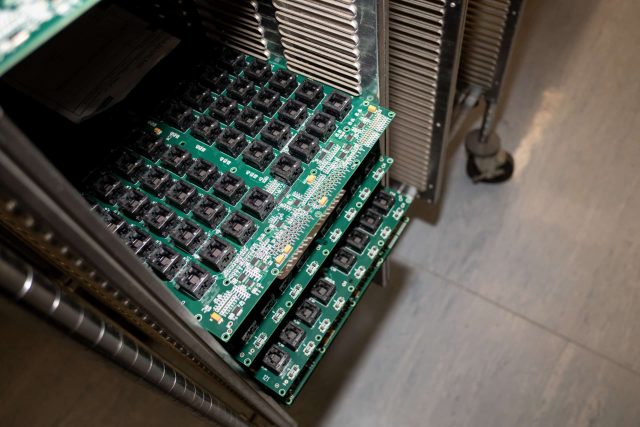

High-volume reliability qualification testing

The durability and stability of the burn-in PCB directly impact testing accuracy and efficiency.

Key Requirements for Burn-in Board PCBs

Burn-in board PCBs must withstand extreme operating conditions and repeated test cycles. Key requirements include:

-

High temperature resistance for long burn-in cycles

-

High pin count support for complex IC packages

-

Stable power delivery and grounding

-

Controlled impedance routing for high-speed signals

-

Excellent mechanical strength and flatness

-

Long service life under thermal cycling

These requirements make burn-in PCBs significantly more demanding than standard test boards.

Design Considerations for Burn-in Board PCBs

Effective burn-in board PCB design includes:

-

Optimized multilayer stackup for thermal and electrical performance

-

Reinforced copper structures for power distribution

-

High-reliability via and pad design

-

Socket footprint optimization for thermal expansion

-

Thermal management solutions for heat dissipation

Close coordination between PCB designers, reliability engineers, and test system providers is essential.

Materials Used in Burn-in Board PCBs

Burn-in board PCBs require materials that maintain electrical and mechanical stability under high temperatures. Common materials include:

-

High-TG FR-4 laminates

-

Polyimide PCB materials for extreme temperature environments

-

Low CTE materials for dimensional stability

-

High thermal performance prepregs

Material selection depends on burn-in temperature range, typically between 125°C and 200°C or higher.

Manufacturing Capabilities

A professional burn-in board PCB manufacturer should provide:

-

Multilayer PCB fabrication for complex routing

-

Controlled impedance manufacturing and validation

-

Heavy copper options for high current applications

-

Tight tolerance drilling and plating control

-

High reliability surface finishes such as ENIG or hard gold

-

Small batch and prototype manufacturing with fast delivery

Precision manufacturing ensures consistent performance during long burn-in test cycles.

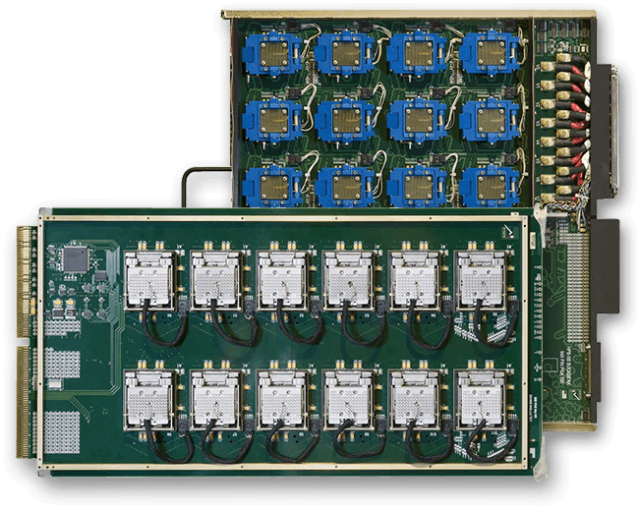

Assembly Considerations

Burn-in board PCB assembly typically includes:

-

High-temperature burn-in sockets

-

Power connectors and signal interface components

-

Passive components for filtering and protection

-

Mechanical reinforcement for long-term durability

Proper assembly techniques ensure reliable electrical contact and thermal stability throughout the burn-in process.

Applications of Burn-in Board PCBs

Burn-in board PCBs are widely used in:

-

Semiconductor reliability qualification testing

-

Automotive electronics burn-in testing

-

Aerospace and defense IC reliability validation

-

Industrial and power semiconductor testing

-

High-reliability communication device screening

They are essential for ensuring product reliability in mission-critical applications.

Why Choose a Specialized Burn-in Board PCB Supplier

An experienced burn-in PCB supplier offers:

-

Expertise in high-temperature PCB materials and design

-

Stable quality for long burn-in test cycles

-

Optimized thermal and power distribution solutions

-

Fast prototype and small batch production

-

Engineering support from design review to final assembly

Selecting the right partner improves reliability screening efficiency and reduces failure risks.