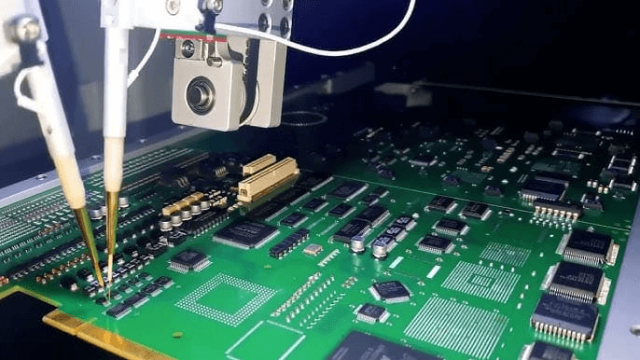

An ATE Test PCB is a critical component in automated test equipment used for semiconductor and electronic product testing. ATE systems rely on highly reliable PCBs to ensure accurate signal transmission, repeatable measurements, and long-term stability during high-cycle testing operations.

As semiconductor devices continue to evolve toward higher speed, higher integration, and smaller geometries, ATE test PCBs must meet increasingly stringent electrical, mechanical, and reliability requirements.

What Is an ATE Test PCB?

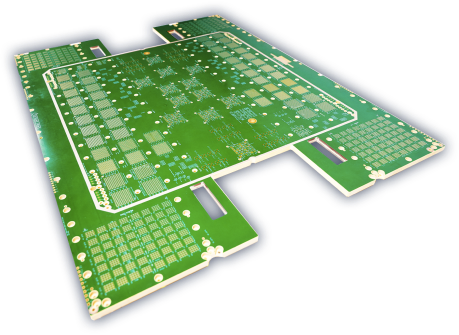

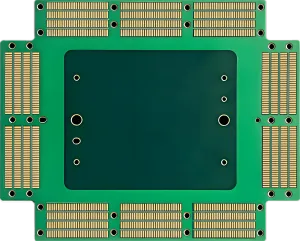

An ATE Test PCB is a specialized printed circuit board designed for use in automated test equipment that verifies the functionality, performance, and reliability of electronic components and integrated circuits. These PCBs serve as the interface between the device under test (DUT) and the ATE system.

ATE test PCBs often include complex routing, controlled impedance traces, high pin-count connectors, and robust mechanical structures to support repeated testing cycles.

Key Requirements for ATE Test PCB Manufacturing

High Signal Integrity

ATE test PCBs must support high-speed digital and analog signals with minimal distortion, requiring precise impedance control and optimized stack-up design.

Mechanical Durability

ATE environments involve frequent insertion, removal, and mechanical stress. ATE test PCBs must withstand thousands of test cycles without degradation.

Thermal Stability

Power-intensive testing generates heat. Stable materials and effective thermal management are essential to maintain measurement accuracy.

Manufacturing Consistency

Repeatability is critical in ATE test PCB manufacturing to ensure consistent test results across multiple systems and production batches.

Materials Used in ATE Test PCB Manufacturing

Materials selection directly affects performance and reliability.

Common materials include:

-

High-Tg FR-4 for standard test applications

-

Low-loss laminates for high-speed and RF testing

-

Hybrid stack-ups combining FR-4 with high-frequency materials

-

Specialized materials for high-temperature and long-life testing

An experienced ATE test PCB manufacturer assists in selecting materials that balance performance, durability, and cost.

Manufacturing Capabilities for ATE Test PCB

Professional ATE test PCB manufacturing requires advanced production technologies:

-

Multilayer and high layer count PCB fabrication

-

Controlled impedance PCB processing

-

Fine line and space etching

-

Laser drilling for microvias

-

Robust surface finishes such as ENIG or hard gold

-

Electrical testing and impedance verification

Strict quality control ensures long-term reliability in demanding test environments.

Design Challenges and Engineering Support

Designing an ATE test PCB presents unique challenges:

-

High-density routing for large pin-count devices

-

Signal isolation and crosstalk control

-

Connector and socket integration

-

Via durability and plating reliability

-

EMI control and grounding optimization

Experienced ATE PCB manufacturers provide DFM, DFT, and engineering support to optimize design performance and manufacturability.

Applications of ATE Test PCBs

ATE test PCBs are widely used in:

-

Semiconductor wafer testing

-

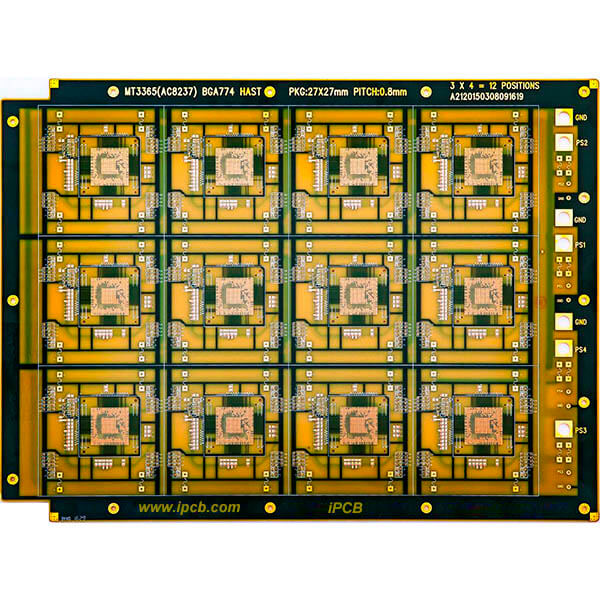

IC package testing

-

Burn-in and reliability testing

-

Logic and functional testing

-

Memory and processor validation

-

Automotive and industrial electronics testing

In these applications, stable and repeatable test performance is essential.

ATE Test PCB from Prototype to Mass Production

ATE test PCB projects typically start with prototype validation to verify signal integrity, mechanical strength, and connector performance. Once approved, designs are scaled to small-batch or volume production with consistent materials and controlled processes.

Working with a single supplier throughout this process ensures performance continuity and supply stability.

Conclusion

An ATE Test PCB is a mission-critical component in automated test equipment and semiconductor validation systems. By combining high-reliability materials, precise impedance control, and advanced manufacturing processes, professional ATE test PCB manufacturers deliver solutions that ensure accurate testing and long-term durability.

As semiconductor testing requirements become more demanding, partnering with an experienced ATE test PCB supplier is essential for achieving reliable, repeatable, and scalable test performance.