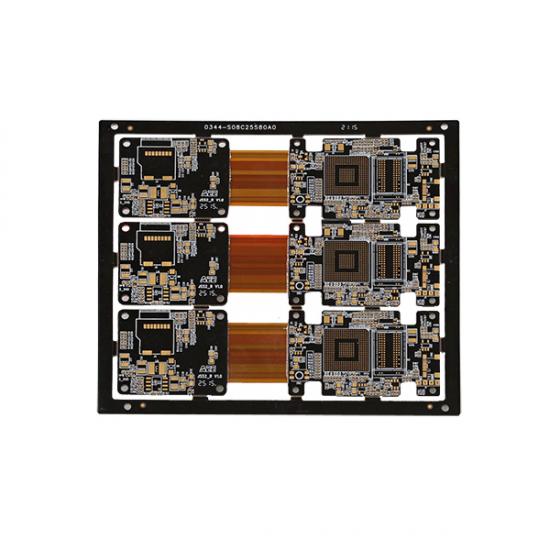

A multilayer rigid-flex PCB manufacturer specializes in producing printed circuit boards that combine rigid PCB sections with flexible circuits into a single integrated structure. Multilayer rigid-flex PCBs offer superior electrical reliability, space savings, and mechanical durability, making them ideal for advanced electronic applications where performance and compact design are critical.

As modern electronics move toward miniaturization, lightweight structures, and high functional integration, multilayer rigid-flex PCB solutions have become essential across industries such as aerospace, medical devices, automotive electronics, and industrial automation.

What Is a Multilayer Rigid-Flex PCB?

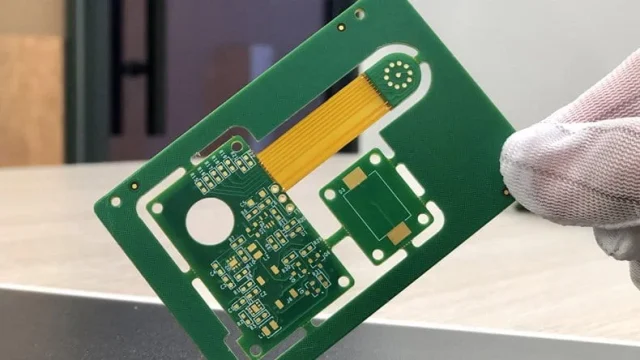

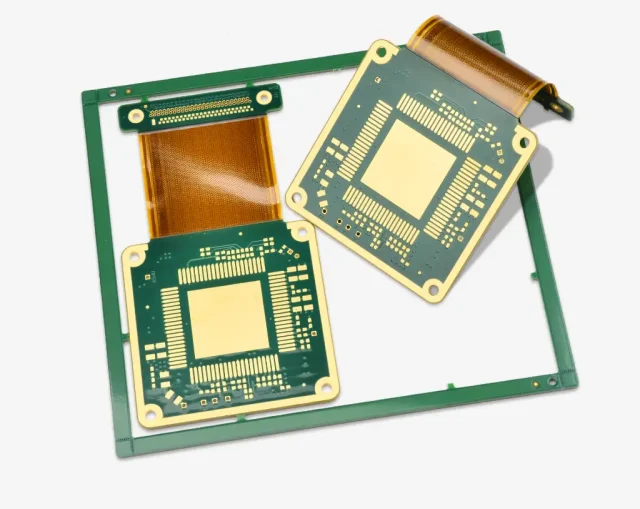

A multilayer rigid-flex PCB consists of multiple rigid PCB layers interconnected with flexible polyimide layers. Unlike traditional rigid PCBs or standalone flex circuits, rigid-flex PCBs eliminate connectors and cables, significantly improving signal integrity and system reliability.

Typical multilayer rigid-flex PCB structures include:

-

Rigid FR-4 sections for component mounting

-

Flexible polyimide layers for dynamic bending

-

Multiple copper layers for signal, power, and ground

-

Blind and buried vias for HDI interconnection

Advantages of Multilayer Rigid-Flex PCB Technology

Choosing a professional multilayer rigid-flex PCB manufacturer provides several key advantages:

1. Enhanced Reliability

Rigid-flex PCBs reduce solder joints, connectors, and wiring, minimizing failure points in high-reliability systems.

2. Space and Weight Reduction

Multilayer rigid-flex designs allow compact layouts and lightweight assemblies, ideal for portable and aerospace applications.

3. Improved Signal Integrity

Shorter signal paths and controlled impedance routing improve electrical performance in high-speed and high-frequency designs.

4. Design Flexibility

Flexible sections enable complex 3D packaging and dynamic movement without compromising electrical stability.

Manufacturing Capabilities of a Multilayer Rigid-Flex PCB Manufacturer

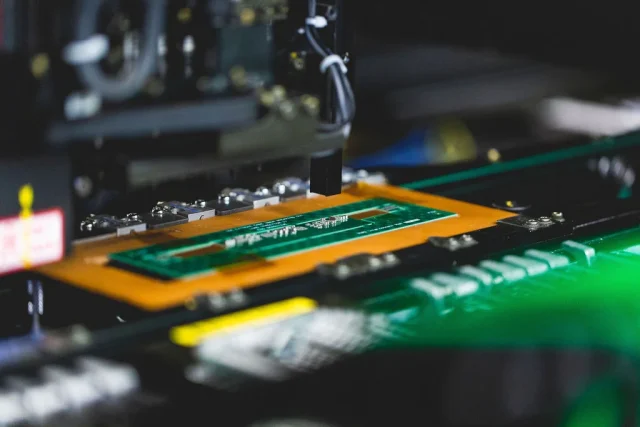

A qualified multilayer rigid-flex PCB manufacturer must offer advanced fabrication technologies and strict process control.

Advanced Layer Stack-Up Design

Support for 4–20+ layer rigid-flex structures, including complex hybrid stack-ups.

HDI and Microvia Technology

Laser-drilled microvias, blind vias, and buried vias for high-density interconnect designs.

Material Expertise

-

Polyimide flexible materials

-

High Tg FR-4 rigid materials

-

Low-loss laminates for high-speed applications

Precision Lamination Process

Controlled lamination cycles to prevent delamination, warpage, and mechanical stress.

Surface Finish Options

ENIG, ENEPIG, immersion silver, immersion tin, and hard gold for high-reliability requirements.

Design Considerations for Multilayer Rigid-Flex PCBs

Successful rigid-flex PCB manufacturing starts with proper design:

-

Bend radius optimization to avoid copper cracking

-

Flexible area copper balancing

-

Controlled impedance design

-

Via placement away from bend zones

-

Mechanical reinforcement in high-stress areas

An experienced rigid-flex PCB manufacturer provides DFM and engineering support to optimize design reliability.

Applications of Multilayer Rigid-Flex PCBs

Multilayer rigid-flex PCBs are widely used in demanding environments:

Aerospace and Defense

Avionics systems, satellites, and communication modules requiring extreme reliability.

Medical Devices

Implantable devices, imaging systems, and diagnostic equipment with compact and complex designs.

Automotive Electronics

ADAS systems, infotainment modules, and vehicle control units.

Industrial Automation

Robotics, motion control systems, and smart factory equipment.

Consumer Electronics

Wearables, cameras, and foldable electronic devices.

Why Choose a Professional Multilayer Rigid-Flex PCB Manufacturer

Partnering with an experienced manufacturer ensures:

-

Stable quality and long-term reliability

-

Advanced manufacturing capabilities

-

Engineering and DFM support

-

Fast prototype and scalable production

-

Compliance with international quality standards

A reliable multilayer rigid-flex PCB manufacturer supports projects from prototype development to mass production.

Conclusion

Multilayer rigid-flex PCB technology enables compact, reliable, and high-performance electronic systems. Selecting the right multilayer rigid-flex PCB manufacturer is critical to achieving consistent quality, advanced functionality, and long product lifecycle performance. As electronic designs continue to evolve, rigid-flex PCBs will remain a key solution for next-generation electronic applications.