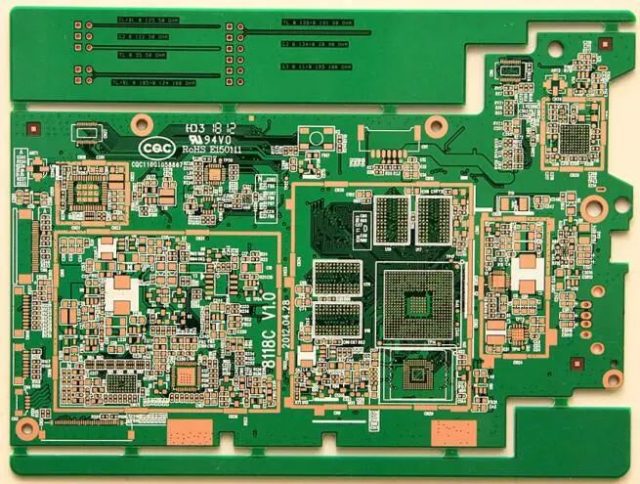

What Is a High Speed PCB?

A High Speed PCB is a printed circuit board designed to support high-speed digital signals, typically operating at multi-gigabit data rates. These PCBs are essential for modern electronics where signal integrity, timing accuracy, and low noise are critical.

High speed PCBs are widely used in servers, networking equipment, semiconductor test systems, and advanced communication devices.

Key Requirements for High Speed PCB

High speed PCBs must meet strict electrical performance requirements:

-

Controlled impedance for high-speed signal traces

-

Low insertion loss and crosstalk

-

Tight skew control for differential pairs

-

Stable dielectric properties over frequency

-

Low jitter and minimal signal distortion

-

Strong power and ground integrity

These factors directly affect data transmission quality.

Materials Used in High Speed PCB

Material selection is critical for high speed PCB performance:

-

Low-loss, high-speed laminates (Megtron 7, RO4350B, RO4835)

-

High-Tg FR-4 for mid-speed designs

-

Hybrid stack-ups combining RF and digital layers

-

Ultra-low loss materials for very high data rates

The right material ensures reliable high-speed signal transmission.

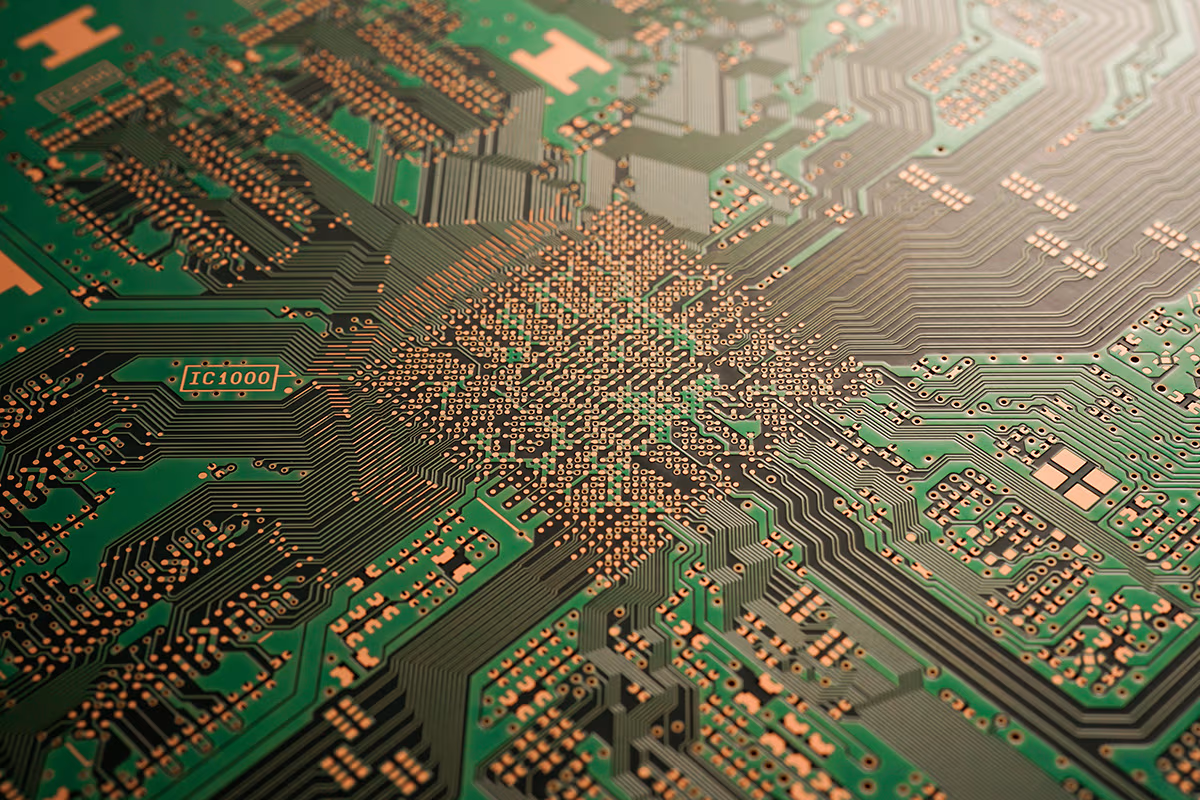

Design Considerations for High Speed PCB

Designing a high speed PCB requires advanced signal integrity expertise:

-

Precise impedance control and stack-up design

-

Differential pair routing and length matching

-

Minimization of vias and stubs

-

Optimized power distribution network (PDN)

-

EMI and crosstalk control

-

HDI structures for dense, high-speed designs

Simulation and verification are essential.

Manufacturing Challenges of High Speed PCB

Manufacturing high speed PCBs involves tight process control:

-

Precise dielectric thickness control

-

Accurate copper etching and plating

-

Controlled lamination for multilayer stack-ups

-

Reliable via drilling and back drilling

-

High-quality surface finishes

-

Electrical testing and impedance verification

Manufacturing consistency directly impacts signal integrity.

Applications of High Speed PCB

High speed PCBs are widely used in:

-

High-speed networking and switches

-

Data centers and servers

-

Semiconductor test and load boards

-

High-speed computing and AI hardware

-

Advanced communication systems

-

Industrial and aerospace electronics

They enable reliable high-speed data transmission.

Conclusion

A High Speed PCB is essential for modern electronic systems requiring fast, reliable data transmission. Through optimized materials, precise design, and advanced manufacturing, high speed PCBs deliver excellent signal integrity and long-term reliability.

Working with an experienced High Speed PCB manufacturer ensures consistent impedance control, stable electrical performance, and successful transition from prototype to mass production.