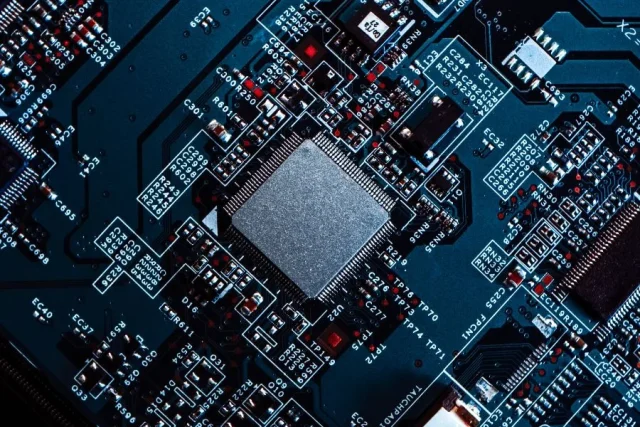

What Is an Industrial Automation PCB?

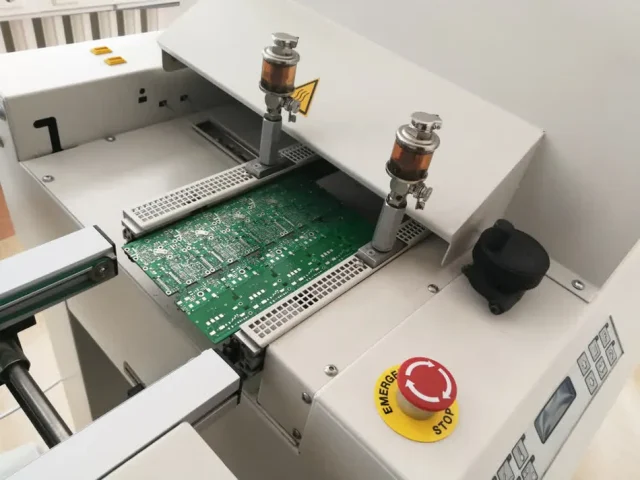

An Industrial Automation PCB is a specialized printed circuit board used in factory automation, industrial control, and process automation systems. These PCBs form the core of PLC controllers, motion control units, industrial communication modules, and power control boards.

Industrial automation PCBs are designed for continuous operation, harsh environments, and long product lifecycles.

Key Requirements for Industrial Automation PCB

Industrial automation PCBs must meet strict performance and reliability requirements:

-

24/7 continuous operation capability

-

High resistance to vibration, dust, and temperature changes

-

Stable power delivery and signal integrity

-

Strong EMI and noise immunity

-

Long-term availability and consistency

-

Compliance with industrial reliability standards

These requirements ensure stable and safe industrial operation.

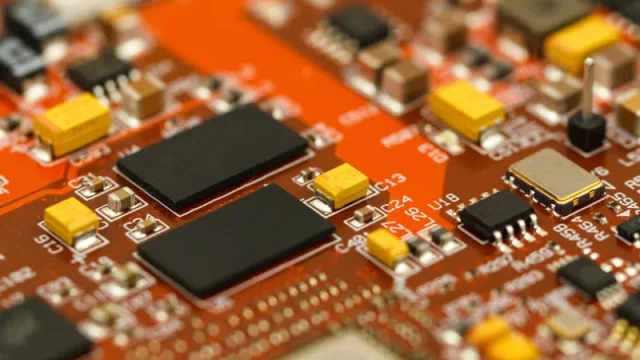

Materials Used in Industrial Automation PCB

Material selection is critical for industrial automation PCB reliability:

-

High-Tg FR-4 for control and logic boards

-

Heavy copper PCB structures for power and current handling

-

Low-loss materials for industrial Ethernet and communication modules

-

Ceramic or Alumina PCB for high-temperature or high-power sections

-

Hybrid PCB materials combining power, control, and signal layers

The right materials ensure durability and electrical stability.

Design Considerations for Industrial Automation PCB

Designing industrial automation PCBs requires industrial-grade engineering:

-

Multilayer PCB stack-up for power, ground, and signal separation

-

Controlled impedance for communication signals

-

Robust grounding and EMI shielding

-

Thermal management for power devices

-

High-voltage isolation and safety spacing

-

Design for manufacturability (DFM) and long-term maintenance

Good PCB design directly affects system uptime and reliability.

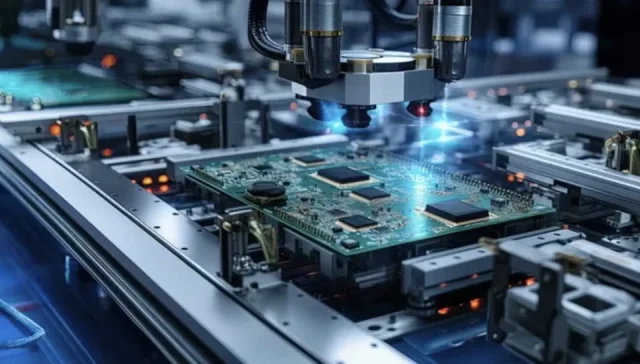

Manufacturing Challenges of Industrial Automation PCB

Manufacturing industrial automation PCBs involves:

-

Precision multilayer lamination

-

Consistent copper thickness and trace geometry

-

Industrial-grade surface finishes (ENIG, HASL, Immersion Silver)

-

Rigorous electrical testing and inspection

-

Process traceability and quality documentation

Experienced manufacturers ensure consistent quality over long production cycles.

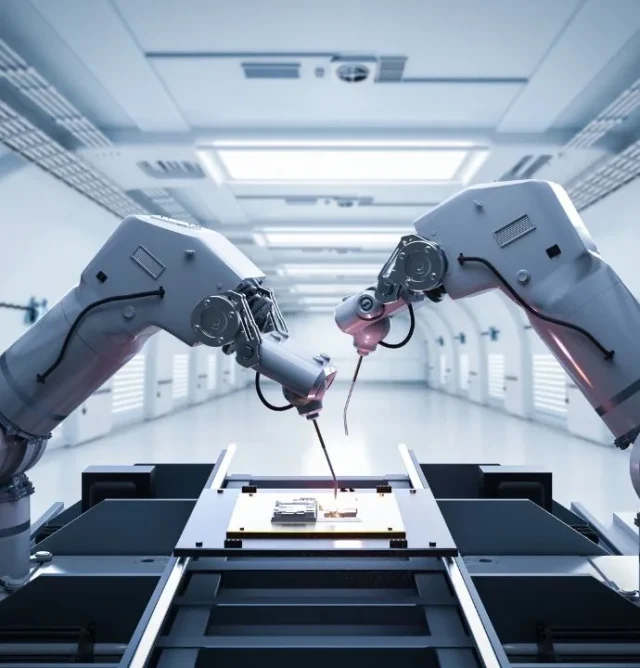

Applications of Industrial Automation PCB

Industrial automation PCBs are widely used in:

-

Programmable logic controllers (PLC)

-

Motion control and servo drive systems

-

Industrial robots and robotic controllers

-

Industrial communication and I/O modules

-

Factory automation equipment

-

Process control and monitoring systems

They are essential for modern industrial automation.

Conclusion

An Industrial Automation PCB is a critical component for reliable and efficient industrial control systems. Through careful material selection, robust design, and precision manufacturing, industrial automation PCBs deliver long-term stability and performance in demanding environments.

Partnering with an experienced Industrial Automation PCB manufacturer ensures consistent quality, long product lifecycle support, and smooth transition from prototype to mass production.