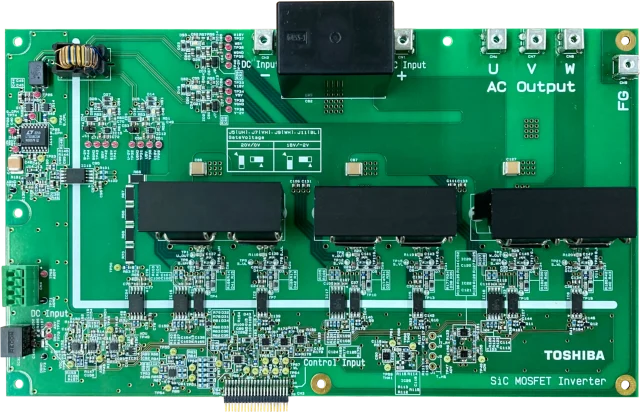

What Is a SiC PCB?

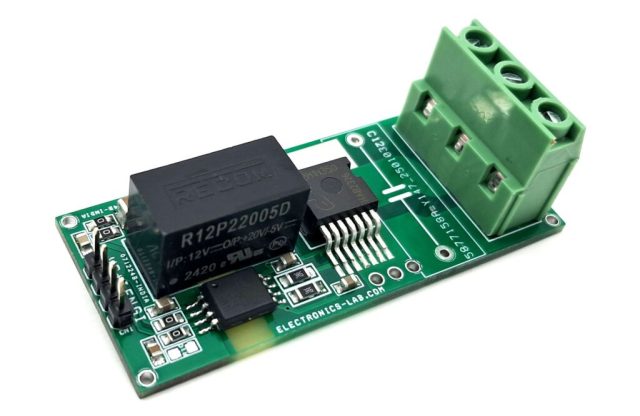

A SiC PCB is a specialized printed circuit board designed for silicon carbide (SiC) power devices, such as SiC MOSFETs and SiC diodes. These PCBs are engineered to operate under high voltage, high current, and high temperature conditions commonly found in advanced power electronics.

Compared with conventional PCBs, SiC PCBs emphasize thermal performance, electrical reliability, and mechanical stability.

Why SiC Devices Require Specialized PCBs

SiC power devices offer major advantages, including:

-

Higher switching frequency

-

Higher operating temperature

-

Lower switching loss

-

Higher power density

To fully leverage these benefits, a SiC PCB must provide:

-

Excellent thermal dissipation

-

Low parasitic inductance

-

High current carrying capability

-

Stable performance under thermal cycling

Standard FR-4 PCBs are often insufficient for SiC applications.

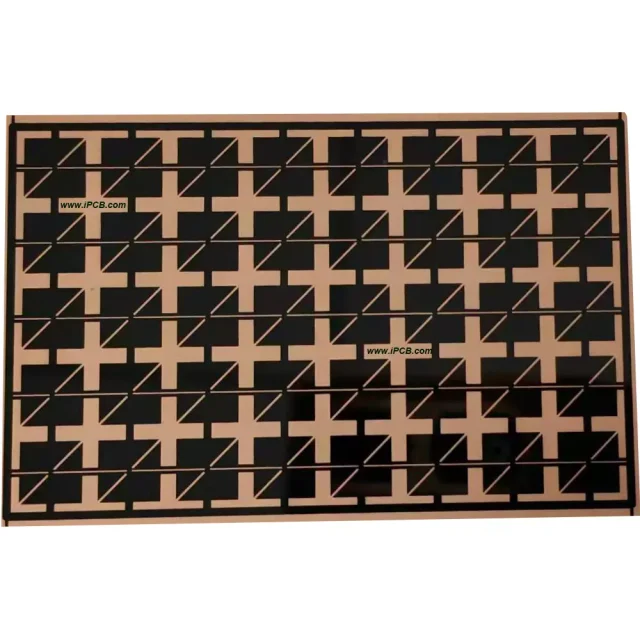

Materials Used in SiC PCB

Material selection is critical for SiC PCB performance:

-

Heavy copper PCB structures for high current paths

-

Ceramic substrates (Alumina, AlN) for superior thermal conductivity

-

Metal core PCBs (MCPCB) for power modules

-

High-Tg, high-temperature laminates for control and gate drive circuits

-

Hybrid PCB materials combining ceramic and organic layers

These materials ensure thermal and electrical reliability.

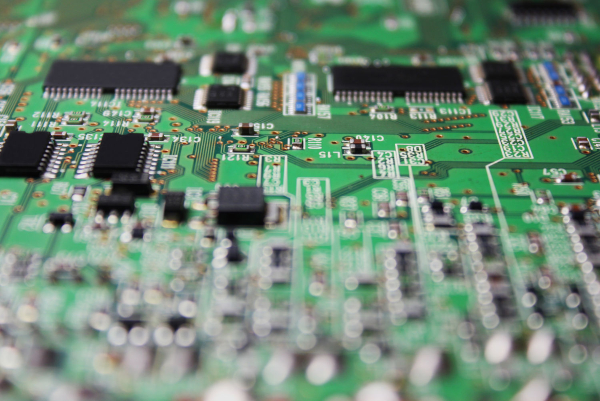

Design Considerations for SiC PCB

Designing a SiC PCB requires advanced power electronics expertise:

-

Low-inductance layout for fast switching SiC devices

-

Wide and thick copper traces

-

Optimized power and ground planes

-

Thermal vias and heat spreading structures

-

Creepage and clearance design for high voltage

-

EMI control for high dv/dt and di/dt

Proper PCB design directly affects SiC system efficiency and reliability.

Manufacturing Challenges of SiC PCB

Manufacturing SiC PCBs involves complex processes:

-

Precision heavy copper etching and plating

-

Advanced ceramic PCB processing

-

Controlled lamination for hybrid structures

-

High-temperature compatible surface finishes

-

Rigorous electrical, thermal, and reliability testing

Only experienced manufacturers can ensure consistent quality.

Applications of SiC PCB

SiC PCBs are widely used in:

-

Electric vehicle (EV) power inverters

-

On-board chargers (OBC)

-

DC-DC converters

-

Renewable energy systems

-

Industrial motor drives

-

High-power robotics and automation equipment

-

Aerospace and defense power electronics

They are essential for next-generation power systems.

Conclusion

A SiC PCB is a critical enabler for modern high-power and high-efficiency power electronics. By combining advanced materials, optimized layout, and precision manufacturing, SiC PCBs support the full performance potential of silicon carbide devices.

Working with an experienced SiC PCB manufacturer ensures reliable thermal management, electrical stability, and long-term performance from prototype to production.