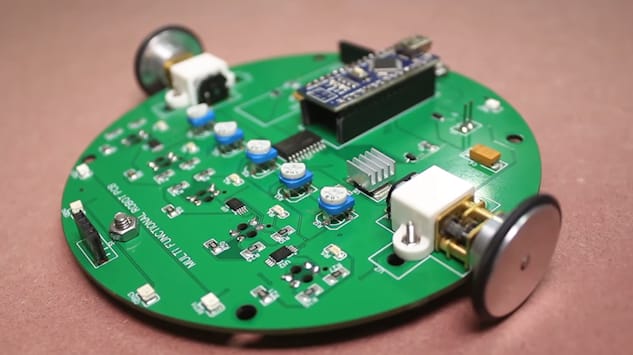

What Is a Robotics PCB?

A Robotics PCB is a specialized printed circuit board used in industrial robots, autonomous machines, and embedded control systems. It provides stable electrical performance, high reliability, and integration of multiple sensors and actuators in compact designs.

Robotics PCBs are critical for precise motion control, real-time feedback, and high-speed communication between modules.

Key Requirements for Robotics PCB

A Robotics PCB must meet strict engineering requirements:

-

Compact and dense layouts for small robots or modules

-

High-reliability materials for long operational lifetime

-

Impedance controlled PCB traces for sensor and communication signals

-

Thermal management for motor drivers and processors

-

Vibration and shock resistance for industrial and mobile robots

These features ensure accurate control, low downtime, and consistent performance.

Materials for Robotics PCB

Material selection is crucial for Robotics PCB reliability and performance:

-

High-Tg FR-4 for standard control electronics

-

Low-loss materials (RO4350B, RF-35, Duroid 5880) for high-speed signal lines

-

Alumina or ceramic PCB for motor driver and high-power modules

-

Hybrid materials for combining RF and digital circuits

Material choice depends on signal frequency, power level, and environmental stress.

Design Considerations for Robotics PCB

Designing Robotics PCBs involves multiple challenges:

-

Multilayer stack-up optimization for power, ground, and signal layers

-

Controlled impedance for high-speed sensor and communication signals

-

HDI and blind/buried via design for dense robotics modules

-

Thermal pathways and heat dissipation for high-power ICs

-

EMI shielding and grounding for reliable sensor readings

Accurate PCB design ensures smooth robot operation and high precision.

Manufacturing Challenges for Robotics PCB

Manufacturing robotics PCBs requires:

-

Precision multilayer lamination

-

Controlled copper thickness and trace width

-

High-quality surface finishes (ENIG, OSP, Immersion Silver)

-

Rigorous electrical and thermal testing

-

Vibration and shock testing for industrial reliability

Experienced manufacturers ensure consistent quality for robotics applications.

Applications of Robotics PCB

Robotics PCBs are used in:

-

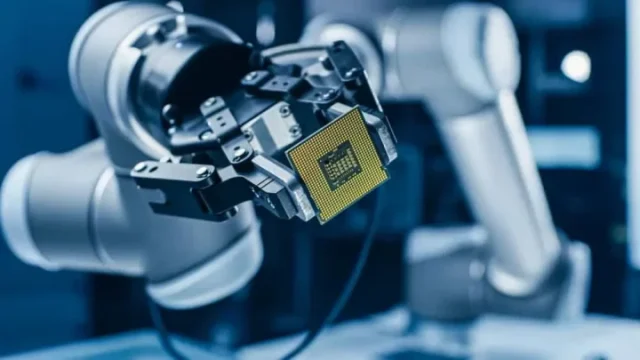

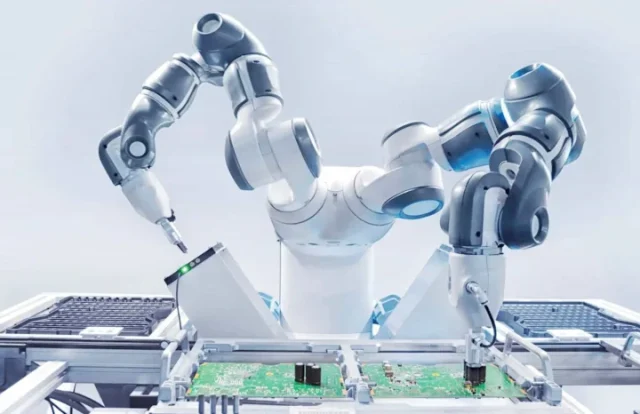

Industrial robots and manipulators

-

Autonomous vehicles and drones

-

Medical robots and surgical devices

-

Mobile service robots

-

Automated inspection and factory automation systems

-

High-speed sensor and communication modules in robotics

They are essential for reliable, precise, and intelligent robotic systems.

Conclusion

A Robotics PCB is the backbone of modern robotic and automation systems. Through high-quality materials, precision design, and advanced manufacturing, Robotics PCBs deliver reliable performance in complex, high-speed, and high-reliability environments.

Partnering with an experienced Robotics PCB manufacturer ensures optimized material selection, consistent electrical performance, and reliable delivery from prototype to production.