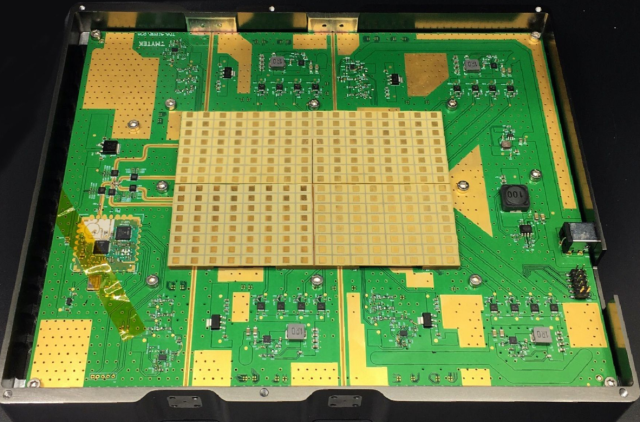

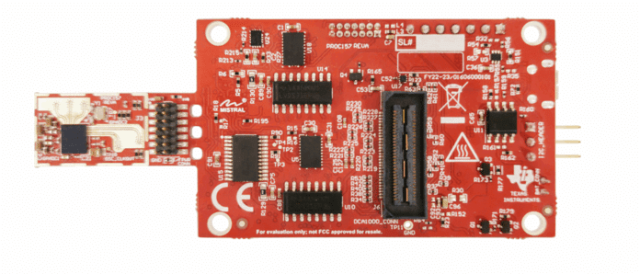

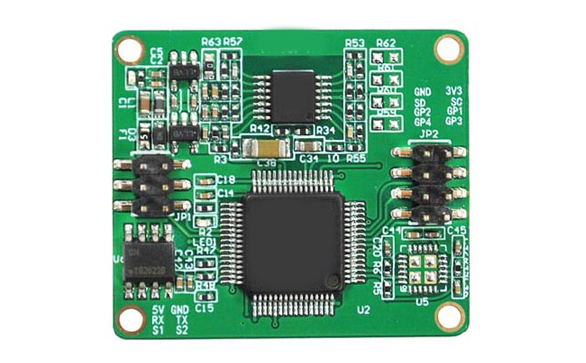

What Is a mmWave Module PCB?

A mmWave Module PCB is a specialized printed circuit board designed to operate at millimeter-wave frequencies (typically 24 GHz to 110 GHz). These PCBs are used in compact RF modules where signal loss, impedance variation, and electromagnetic interference must be tightly controlled.

mmWave module PCBs are core components in 5G communication, automotive radar, high-frequency sensor modules, and advanced wireless systems.

Key Technical Requirements of mmWave Module PCB

Millimeter-wave operation places extremely strict requirements on PCB performance:

-

Ultra-low dielectric loss at mmWave frequencies

-

Highly stable dielectric constant (Dk)

-

Precise impedance controlled PCB structures

-

Minimal insertion loss and reflection

-

Excellent RF shielding and grounding

-

High dimensional accuracy and consistency

Any small variation in PCB structure can significantly impact mmWave performance.

Material Selection for mmWave Module PCB

Material choice is critical for mmWave Module PCB performance. Common materials include:

-

Rogers RO4350B / RO4835 PCB

-

RF-35 PCB

-

Panasonic Megtron 7 PCB

-

Advanced low-loss hybrid PCB materials

These materials offer low Df, stable Dk, and good thermal reliability for mmWave applications.

Stack-Up and Impedance Control Design

mmWave Module PCBs rely on precise stack-up and impedance control:

-

Microstrip, stripline, and CPWG structures

-

Tight control of dielectric thickness

-

Low-profile copper foil to reduce conductor loss

-

Short, well-designed via transitions

-

Ground stitching vias for RF isolation

Accurate impedance controlled PCB design is essential for stable mmWave signal transmission.

Manufacturing Challenges for mmWave Module PCB

Producing reliable mmWave Module PCBs requires advanced manufacturing capabilities:

-

Extremely tight etching and registration tolerance

-

Controlled copper roughness and plating thickness

-

High-precision drilling and laser processing

-

Advanced lamination control for multilayer HF PCB

-

RF testing and impedance verification

Only experienced high-frequency PCB manufacturers can meet mmWave requirements consistently.

Applications of mmWave Module PCB

mmWave module PCBs are widely used in:

-

5G mmWave base stations and routers

-

Automotive radar and ADAS systems

-

High-frequency sensor and imaging modules

-

Wireless backhaul and point-to-point communication

-

Aerospace and defense RF systems

They enable ultra-high-speed wireless connectivity and high-resolution sensing.

Conclusion

A mmWave Module PCB is a critical enabler for millimeter-wave communication and sensing technologies. Through ultra-low-loss materials, precise impedance control, optimized stack-up design, and advanced manufacturing, mmWave module PCBs deliver reliable performance at extremely high frequencies.

Selecting a professional mmWave Module PCB manufacturer ensures consistent quality, stable RF performance, and reliable delivery from prototype development to volume production.