What Is a Burn-in PCB?

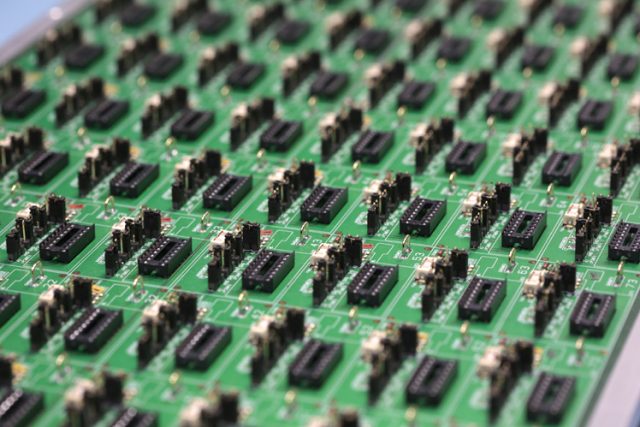

A Burn-in PCB is a specialized printed circuit board used for burn-in testing, where electronic components or assemblies are operated under elevated temperature, voltage, and current conditions for an extended period. The purpose of a Burn-in PCB is to identify early-life failures and verify long-term reliability before products enter mass production.

Compared with standard PCBs, Burn-in PCBs are designed to withstand continuous thermal stress, high current loads, and repeated test cycles without electrical or mechanical degradation.

Key Design Requirements for Burn-in PCB

Reliable Burn-in PCB design is critical to successful stress testing. Key requirements include:

-

High thermal resistance

Stable performance under elevated temperatures and long-duration testing. -

High-current capability

Wide traces, thick copper, and robust vias to handle continuous current flow. -

Efficient thermal management

Copper planes, thermal vias, or metal-core structures for heat dissipation. -

Mechanical durability

Resistance to warpage and fatigue from repeated insertion into burn-in systems. -

Stable electrical characteristics

Minimal resistance change under temperature and load variations.

These design factors ensure consistent and repeatable burn-in test results.

Materials Used in Burn-in PCB

Material selection is critical for Burn-in PCB reliability:

-

High-Tg FR-4 laminates

Suitable for moderate temperature burn-in testing. -

Metal-Core PCBs (MCPCB)

Excellent thermal performance for high-power burn-in applications. -

Ceramic PCBs

Superior thermal stability and low expansion for demanding environments. -

High-reliability hybrid materials

Used when both thermal and electrical performance are required.

Choosing the right materials ensures long service life during repeated burn-in cycles.

Burn-in PCB Manufacturing Considerations

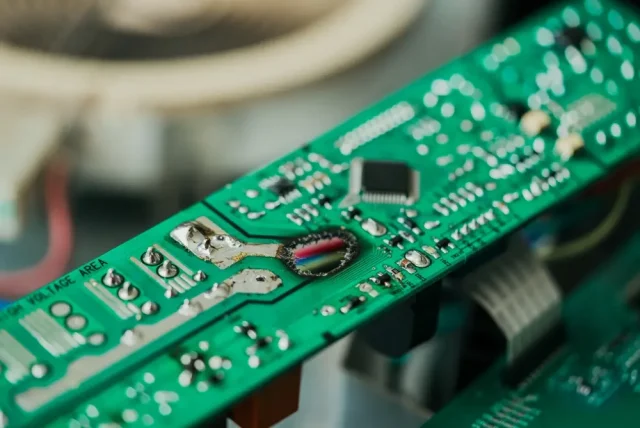

Manufacturing a Burn-in PCB requires stricter process control than standard PCBs:

-

Thick copper plating and reinforced vias

-

Precise lamination and layer alignment

-

High-temperature-resistant solder mask

-

Durable surface finishes

ENIG, hard gold, or immersion silver for stable contact performance. -

Electrical and thermal reliability testing

Experienced Burn-in PCB manufacturers ensure boards remain stable throughout extended stress testing.

Advantages of Using Burn-in PCB

Using a dedicated Burn-in PCB provides key advantages:

-

Early detection of latent defects

-

Improved product reliability and yield

-

Reduced field failure and warranty risk

-

Consistent and repeatable stress test conditions

-

Compliance with strict quality and reliability standards

Burn-in PCBs play a critical role in quality assurance for high-reliability electronics.

Applications of Burn-in PCB

Burn-in PCBs are widely used in industries requiring high reliability:

-

Semiconductor and IC burn-in testing

-

Power electronics and automotive modules

-

Medical electronics reliability verification

-

Telecommunication and networking equipment

-

Industrial and aerospace electronics

They are essential wherever products must operate reliably under harsh conditions.

Burn-in PCB vs Standard Test PCB

Compared to standard test PCBs, Burn-in PCBs feature:

-

Higher thermal resistance

-

Greater current-carrying capability

-

Stronger mechanical durability

-

Longer operational life under stress

These differences make Burn-in PCBs uniquely suited for accelerated aging tests.

Conclusion

A Burn-in PCB is a critical tool for accelerated stress testing and long-term reliability verification of electronic products. From high-temperature materials and thick copper design to precise manufacturing control, every detail affects burn-in performance.

Choosing an experienced Burn-in PCB supplier ensures stable, durable, and high-quality boards capable of supporting demanding burn-in environments and improving overall product reliability.