What Is a Rigid-Flex PCB?

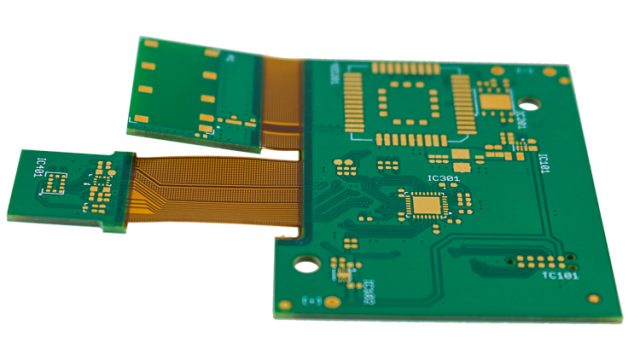

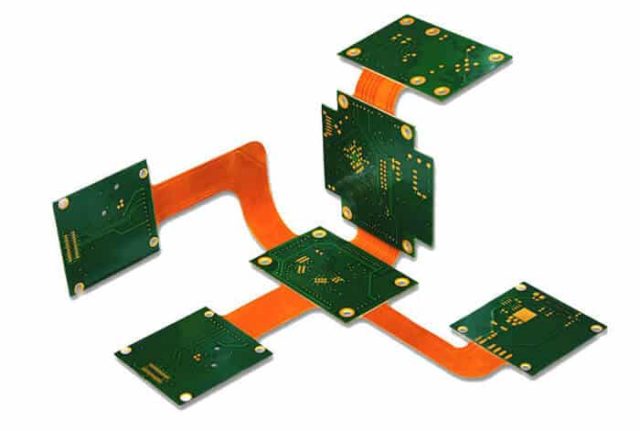

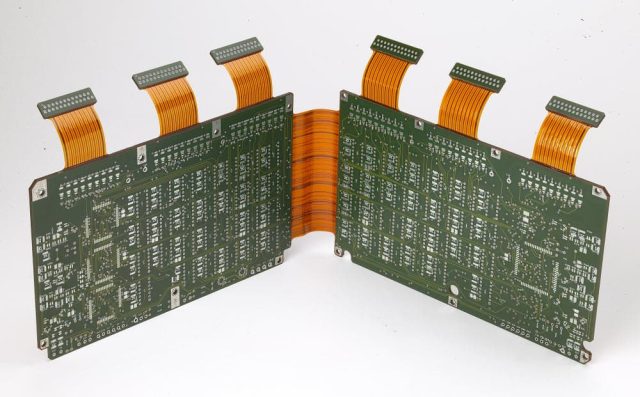

A Rigid-Flex PCB is a printed circuit board that combines rigid sections and flexible sections into a single unit. The rigid areas provide mechanical support and component mounting, while the flexible sections allow bending, folding, or flexing in compact assemblies.

Rigid-Flex PCBs are widely used in high-reliability, space-constrained electronic devices, such as smartphones, wearable devices, medical equipment, and aerospace systems.

Key Features of Rigid-Flex PCB

-

Hybrid structure

Combines rigid and flexible PCB technologies in one board. -

Space-saving design

Reduces the need for connectors and cables. -

High reliability

Eliminates solder joint failures caused by repeated flexing. -

Complex routing

Supports multilayer circuits with fine traces. -

Thermal and mechanical stability

Flexible sections absorb stress while rigid sections maintain structural integrity.

These features make Rigid-Flex PCBs ideal for modern electronics with high-density and high-performance requirements.

Rigid-Flex PCB Manufacturing Process

Manufacturing a Rigid-Flex PCB requires advanced techniques:

-

Layer stack-up design

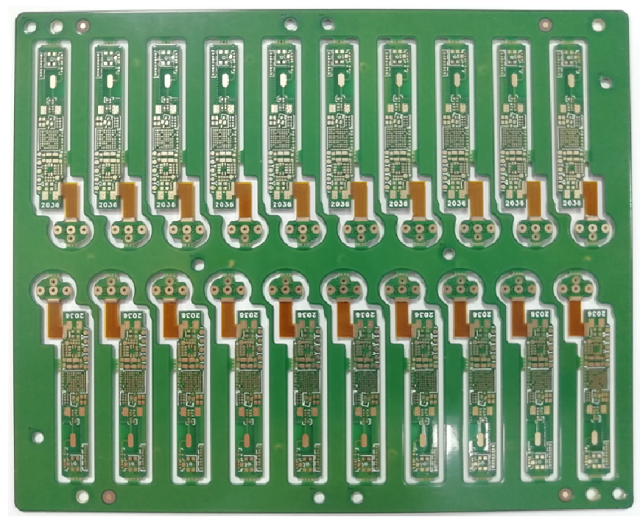

Combines rigid and flexible layers into a single layout. -

Flexible laminate preparation

Polyimide films or other flexible substrates are used. -

Sequential lamination

Rigid and flexible layers are bonded with precision. -

Drilling and via formation

Microvias, blind/buried vias, and through-vias connect layers. -

Surface finish and solder mask

ENIG, hard gold, OSP, or immersion silver for reliable assembly. -

Inspection and testing

Electrical testing, AOI, and flex testing to ensure durability.

Precise process control is critical to prevent delamination, warping, or electrical failure.

Advantages of Rigid-Flex PCB

-

Reduced assembly complexity

Fewer connectors and interconnections needed. -

Enhanced durability

Flexible areas reduce mechanical stress on components. -

Compact product design

Supports miniaturized and foldable electronic assemblies. -

High-density routing

Multilayer capability enables complex circuitry in a small footprint. -

Reliable electrical performance

Maintains signal integrity even under flexing and movement.

Rigid-Flex PCBs are the preferred choice for applications requiring both flexibility and robustness.

Applications of Rigid-Flex PCB

Rigid-Flex PCBs are widely applied in:

-

Smartphones, tablets, and wearable devices

-

Medical devices and diagnostic equipment

-

Aerospace and defense electronics

-

Industrial control and robotics

-

Automotive electronics

Their combination of compact size, mechanical durability, and electrical reliability makes them essential for advanced electronics.

Conclusion

A Rigid-Flex PCB provides a highly reliable, compact, and flexible solution for modern electronic devices. By combining rigid and flexible sections into a single board, engineers can achieve space-saving designs, reduce assembly complexity, and improve long-term reliability.

Partnering with an experienced Rigid-Flex PCB manufacturer ensures precise fabrication, high-quality materials, and superior performance for even the most demanding electronic applications.