Ceramic PCB: The Ideal Solution for Heat Dissipation and High-Reliability Electronics

As electronic products become smaller, more powerful, and more integrated, thermal management has become one of the biggest challenges in modern PCB design. In applications such as power modules, high-brightness LEDs, automotive electronics, and industrial control systems, standard FR4 boards may struggle with heat dissipation and long-term reliability.

That’s where Ceramic PCB stands out. Ceramic-based circuit boards provide high thermal conductivity, excellent electrical insulation, and strong resistance to high temperatures, making them a preferred choice for high-power and high-reliability applications.

In this article, we’ll explain what ceramic PCBs are, their key benefits, common types, and typical applications.

What Is a Ceramic PCB?

A Ceramic PCB is a circuit board that uses ceramic material as the base substrate instead of traditional FR4. Ceramic substrates are widely used because they offer superior thermal and mechanical properties.

Common ceramic materials include:

-

Alumina (Al₂O₃)

-

Aluminum Nitride (AlN)

-

(In some advanced cases) Silicon Nitride (Si₃N₄)

Compared with standard PCB materials, ceramic substrates provide much better heat transfer and stability in harsh environments.

Key Benefits of Ceramic PCB

1. Excellent Thermal Conductivity

One of the most important advantages of ceramic PCBs is strong heat dissipation performance. This helps:

-

Reduce component temperature

-

Improve power density capability

-

Extend product lifespan

-

Lower failure risk caused by overheating

This is why ceramic PCBs are widely used in power electronics and LED applications.

2. High Temperature Resistance

Ceramic substrates maintain stable performance under high operating temperatures. Ceramic PCB is suitable for applications involving:

-

High-power continuous operation

-

Thermal cycling environments

-

High-temperature industrial equipment

Compared with FR4, ceramic materials are much more stable at elevated temperatures.

3. Strong Electrical Insulation

Ceramic PCBs provide excellent electrical insulation while still allowing efficient heat transfer. This is especially important for:

-

High voltage circuits

-

Power conversion modules

-

Isolation requirements in industrial designs

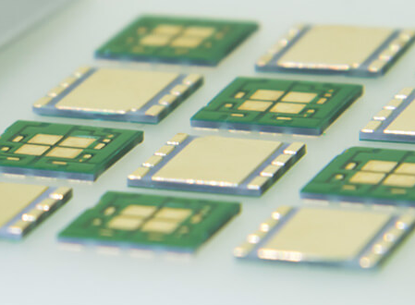

4. High Reliability and Mechanical Stability

Ceramic materials offer strong resistance to warpage and deformation. Ceramic PCBs are commonly used in products that require:

-

Long service life

-

High reliability under vibration or thermal stress

-

Stable mechanical structure for precise assembly

Common Types of Ceramic PCB

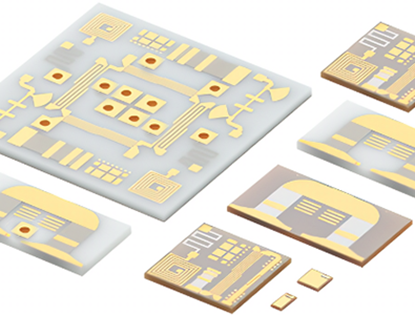

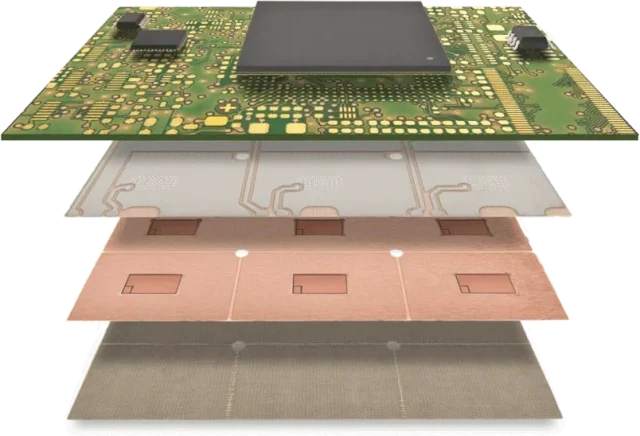

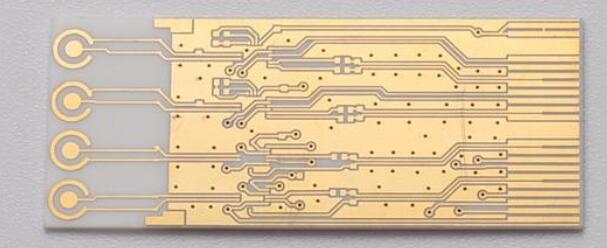

DBC (Direct Bonded Copper) Ceramic PCB

DBC ceramic PCBs bond copper directly onto ceramic substrates, providing:

-

Excellent heat dissipation

-

Strong current carrying capability

-

High reliability for power modules

DBC is widely used in high-power applications such as inverters and motor drives.

AMB (Active Metal Brazing) Ceramic PCB

AMB uses brazing technology to bond copper to ceramic, offering:

-

Strong bonding strength

-

High thermal cycling reliability

-

Better performance in demanding environments

AMB ceramic PCBs are commonly used in automotive and industrial power modules.

Thick Film / Thin Film Ceramic PCB

These ceramic PCBs use printed conductive layers on ceramic substrates and are often used for:

-

Sensors

-

Precision circuits

-

Specialized industrial electronics

They are suitable for compact designs and functional modules.

Typical Applications of Ceramic PCB

Ceramic PCBs are widely used in industries that demand thermal performance and reliability.

LED Lighting Modules

Ceramic PCBs are commonly used for:

-

High-power LED modules

-

Automotive headlights

-

UV LEDs

Better heat dissipation improves brightness stability and lifetime.

Power Modules and Power Electronics

Ceramic PCBs support high-power circuits such as:

-

IGBT modules

-

MOSFET power stages

-

DC-DC converters

-

Inverters and motor control

They help reduce thermal stress and improve efficiency.

Automotive Electronics

Ceramic PCBs are used in automotive systems requiring high reliability, including:

-

EV power control modules

-

Battery management systems (BMS)

-

High-temperature sensor modules

Industrial and High-Reliability Electronics

In industrial environments, ceramic PCBs are applied in:

-

High voltage power supplies

-

Industrial automation equipment

-

High-temperature control systems

Ceramic PCB vs FR4 vs Aluminum PCB

Ceramic PCB is often compared with common thermal management solutions such as FR4 and aluminum-based PCBs.

| Feature | FR4 PCB | Aluminum PCB (IMS) | Ceramic PCB |

|---|---|---|---|

| Thermal Conductivity | Low | Medium | High |

| Electrical Insulation | Good | Good (dielectric layer) | Excellent |

| High Temperature Stability | Moderate | Good | Excellent |

| Reliability | Standard | Good | Very High |

| Typical Use | General electronics | LED & power | High power / high temp |

If your product requires maximum heat dissipation and long-term reliability, ceramic PCB is often the best solution.

Manufacturing Considerations for Ceramic PCB

Producing ceramic PCBs requires specialized manufacturing processes and strict quality control.

Key factors include:

-

Ceramic substrate selection (Al₂O₃ vs AlN)

-

Copper thickness and bonding process (DBC/AMB)

-

Thermal conductivity requirements

-

Precision patterning and etching control

-

Surface finish selection for assembly

-

Inspection and reliability testing

Choosing an experienced manufacturer is essential for stable quality and consistent performance.

Conclusion

Ceramic PCB is an advanced substrate solution designed for high thermal conductivity, strong electrical insulation, and excellent high-temperature stability. It is widely used in LED modules, power electronics, automotive systems, and industrial high-reliability applications, helping products achieve better thermal performance and longer lifespan.

If your project involves high power density or challenging thermal environments, ceramic PCB is a reliable choice worth considering.