Introduction to High Current PCB

A High Current PCB is specifically engineered to safely carry large electrical currents while maintaining excellent thermal performance and long-term reliability. As power levels increase in modern electronics, standard PCB designs often fail to handle excessive heat generation and current density. High Current PCBs address these challenges through thick copper layers, optimized trace geometry, and advanced thermal management techniques.

High Current PCB solutions are widely used in power electronics, automotive systems, industrial equipment, energy storage, and high-power test applications.

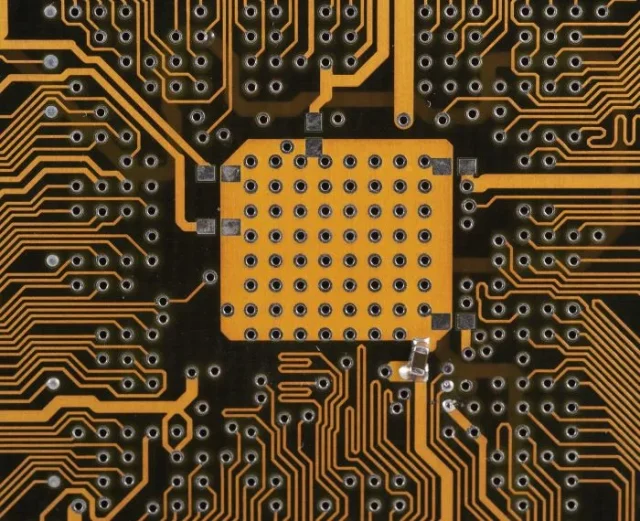

What Is a High Current PCB?

A High Current PCB is designed to handle currents ranging from several amps to hundreds of amps, depending on the application. Unlike conventional PCBs, High Current PCBs use:

-

Heavy copper layers (2 oz to 20 oz or more)

-

Wide and thick copper traces

-

Multiple copper planes for current sharing

-

Low-resistance interconnections

These features reduce resistive losses, minimize voltage drop, and prevent overheating.

Key Design Challenges in High Current PCB

Designing a High Current PCB requires careful consideration of electrical, thermal, and mechanical factors:

-

Excessive heat generation caused by I²R losses

-

Copper trace temperature rise

-

Electromigration risks under continuous high current

-

Uneven current distribution

-

Mechanical stress due to thermal expansion

Professional High Current PCB design ensures stable operation even under harsh working conditions.

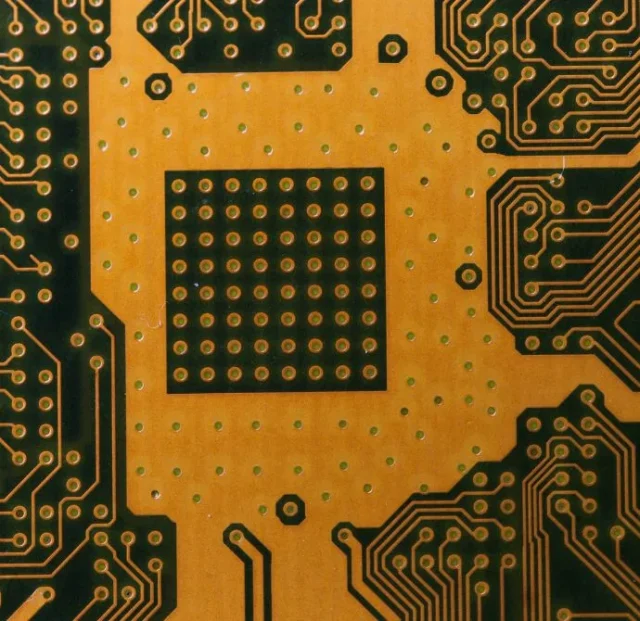

Key Technologies Used in High Current PCB

To meet high-power requirements, High Current PCBs typically incorporate the following technologies:

-

Thick Copper PCB – Enhances current-carrying capacity

-

Copper Bus Bars or Embedded Copper – For ultra-high current paths

-

Multiple Parallel Traces – Improves current distribution

-

Thermal Vias and Heat Sinks – Efficient heat dissipation

-

Wide Spacing and Reinforced Pads – Improves reliability

These techniques significantly improve both power integrity and thermal performance.

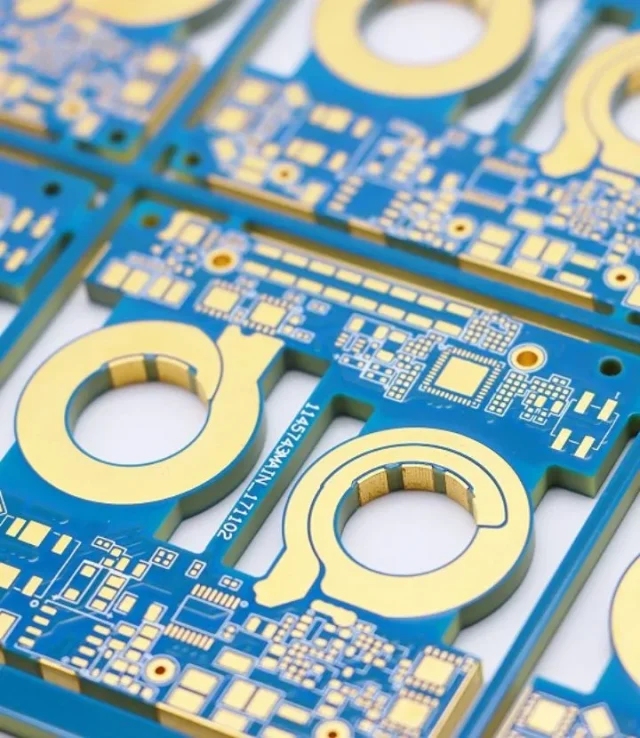

Thermal Management in High Current PCB

Thermal management is critical in High Current PCB design. Common solutions include:

-

Heavy copper planes for heat spreading

-

Metal core or insulated metal substrate (IMS) PCBs

-

High thermal conductivity dielectric materials

-

Thermal vias connecting to heat sinks or chassis

Effective thermal management prevents component failure and extends PCB lifespan.

Applications of High Current PCB

High Current PCBs are essential in industries where power density and reliability are critical:

-

Power supplies and converters

-

Electric vehicles and charging systems

-

Industrial motor drives and inverters

-

Energy storage and battery management systems (BMS)

-

Automated Test Equipment (ATE) and power test boards

These applications demand stable current handling and robust PCB structures.

High Current PCB Manufacturing Considerations

Manufacturing High Current PCBs requires advanced process control, including:

-

Precise copper thickness control

-

High-quality lamination for thick copper layers

-

Accurate etching of wide copper traces

-

Strong adhesion between copper and substrate

-

Comprehensive electrical and thermal testing

Strict quality control ensures consistent performance under high-load conditions.

Why Choose KKPCB for High Current PCB

KKPCB provides professional High Current PCB fabrication and assembly services, supporting:

-

Heavy copper PCB up to ultra-thick copper

-

Custom power PCB and high-current bus designs

-

Advanced thermal management solutions

-

Small batch prototyping and volume production

-

Reliable delivery for industrial and automotive projects

Our engineering team helps optimize current capacity, thermal performance, and cost efficiency.

Conclusion

As electronic systems continue to demand higher power and efficiency, High Current PCB technology plays a critical role in ensuring safe and reliable operation. With proper design, materials, and manufacturing processes, High Current PCBs deliver outstanding performance for power-intensive applications.