In semiconductor mass production, testing does not fail because of the device alone—very often, failures originate from unstable test interfaces. The Test Socket PCB plays a decisive role in ensuring that electrical contact, signal transmission, and mechanical alignment remain consistent across thousands or even millions of test cycles.

A professionally designed Test Socket PCB directly impacts yield stability, false-fail rate, and overall test cost.

Understanding the Role of a Test Socket PCB

A Test Socket PCB is not simply a mechanical carrier. It functions as:

-

The electrical transition layer between socket contacts and test systems

-

A power and ground distribution platform

-

A mechanical reference surface that defines socket alignment

Its performance determines whether the socket can operate reliably throughout its service life.

Contact Consistency: The Core Challenge

Over time, socket contacts experience wear, oxidation, and mechanical fatigue. A poorly designed Test Socket PCB can amplify these issues by:

-

Uneven contact force distribution

-

Localized board flexing

-

Misalignment between socket and DUT

A robust PCB design ensures uniform mechanical support, helping maintain stable contact resistance.

Signal Degradation Across Socket Interfaces

At high data rates, the socket-to-PCB transition becomes a dominant source of signal degradation. Effective Test Socket PCB design focuses on:

-

Short and symmetrical signal escape routing

-

Controlled impedance immediately below the socket pins

-

Minimization of stubs and via discontinuities

These measures reduce reflection, jitter, and eye-diagram collapse during testing.

Power Delivery Under Dynamic Load Conditions

Test sockets often serve devices that switch rapidly between power states. A Test Socket PCB must handle:

-

High transient current demand

-

Fast power sequencing

-

Noise isolation between power domains

Well-designed power planes and local decoupling near the socket are essential for stable test behavior.

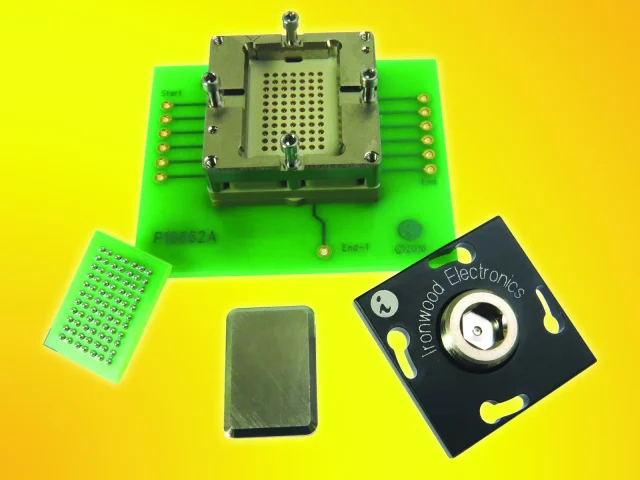

Mechanical Stackup and Board Stiffness

Mechanical deformation is a silent killer in socket-based testing. To prevent it, Test Socket PCBs typically use:

-

Symmetrical multilayer stackups

-

Increased board thickness or local stiffeners

-

Reinforced socket mounting regions

Controlled stiffness helps preserve flatness and coplanarity across repeated insertions.

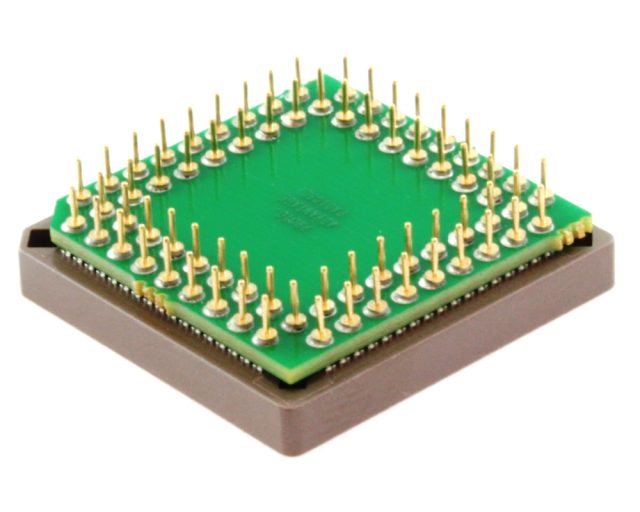

Supporting Fine-Pitch and High-Pin-Count Sockets

As device packages evolve, test sockets follow with tighter pitch and higher pin density. Test socket PCBs must support:

-

Fine-pitch breakout routing

-

HDI structures and microvias

-

Precise hole-to-pad alignment

Manufacturing capability directly impacts socket compatibility.

Material Selection for Long-Term Stability

Material choice affects both electrical and mechanical performance. Common strategies include:

-

High-Tg FR-4 for structural durability

-

Low-loss laminates for high-speed signal paths

-

Hybrid stackups for mixed-signal test environments

Material stability extends socket service life.

Manufacturing Tolerances and Repeatability

A Test Socket PCB used in production must be reproducible. Key manufacturing controls include:

-

Tight thickness and flatness tolerances

-

Consistent plating quality

-

Electrical continuity and impedance verification

Repeatability ensures that replacement boards behave identically in the test system.

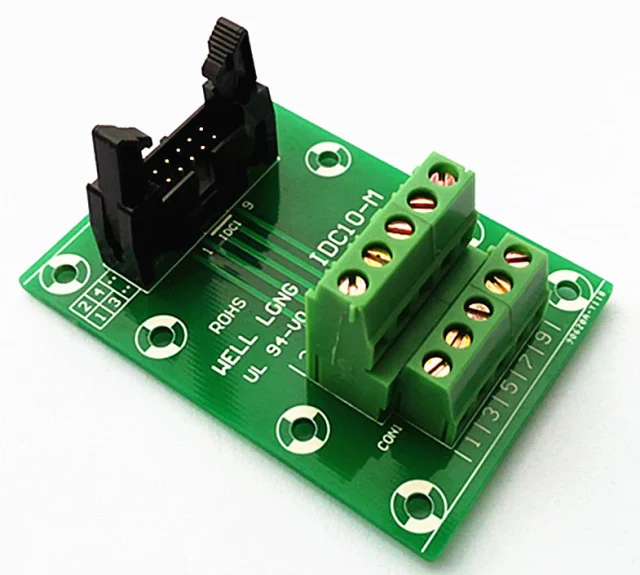

Where Test Socket PCBs Are Commonly Used

Test Socket PCBs are widely deployed in:

-

High-volume final test lines

-

System-level test (SLT) platforms

-

Memory and processor production testing

-

Automotive-grade semiconductor validation

In these environments, uptime and consistency are critical.

Selecting a Test Socket PCB Manufacturing Partner

An experienced Test Socket PCB manufacturer should offer:

-

Proven socket integration experience

-

High pin count and impedance control capability

-

Mechanical and material engineering support

-

Stable quality across repeated production lots

The right partner helps reduce maintenance cost and yield loss.

Conclusion

The Test Socket PCB is a key enabler of reliable, repeatable semiconductor testing. By controlling contact consistency, signal degradation, mechanical stability, and manufacturing repeatability, a well-designed test socket PCB ensures long-term performance in high-cycle production environments.

Working with an experienced Test Socket PCB supplier is essential for sustaining test quality and production efficiency.