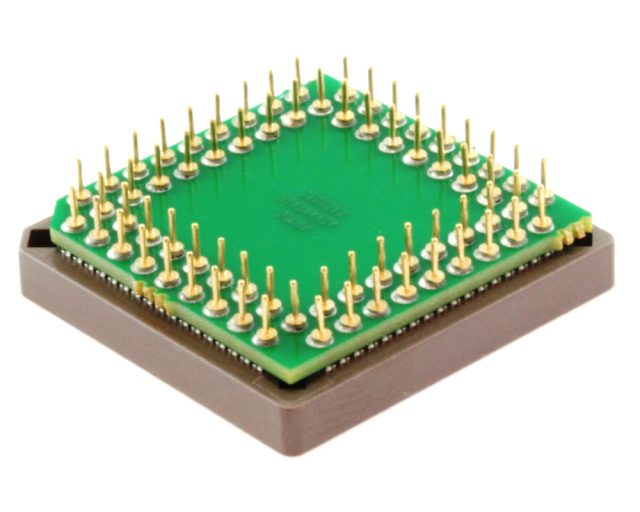

In semiconductor production testing, accurate results depend not only on test equipment and software but also on the physical interface between the device under test (DUT) and the test system. The Test Socket PCB plays a critical role by providing a stable electrical and mechanical foundation for test sockets used in engineering validation and mass production.

A professionally designed Test Socket PCB ensures consistent contact resistance, repeatable signal performance, and long-term test stability.

What Is a Test Socket PCB?

A Test Socket PCB is a specialized printed circuit board designed to mount and support test sockets that interface with packaged semiconductor devices. It connects the DUT to:

-

Load boards or ATE systems

-

Power and ground networks

-

High-speed and mixed-signal test channels

Unlike general-purpose PCBs, test socket PCBs are engineered to withstand frequent insertions and removals while maintaining precise electrical performance.

Why Test Socket PCB Quality Matters

Inconsistent socket PCB performance can lead to:

-

Variable contact resistance

-

Intermittent signal failures

-

Increased false failures during testing

A high-quality Test Socket PCB ensures stable electrical connections across thousands of test cycles.

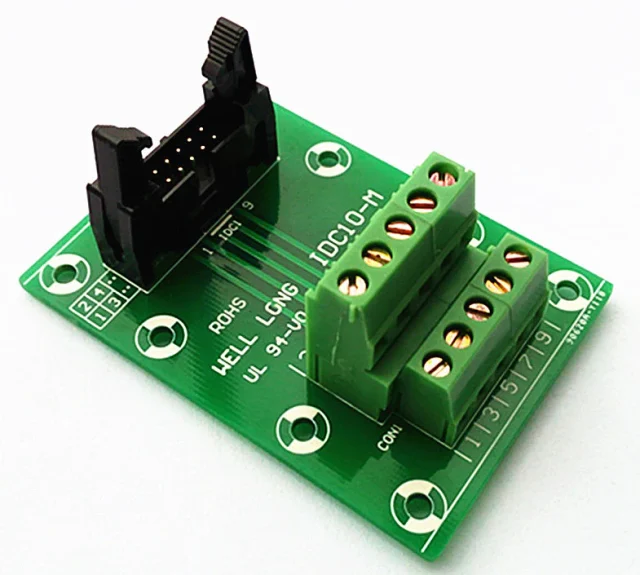

Mechanical Stability and Socket Alignment

Test socket PCBs experience continuous mechanical stress during device insertion. Key design considerations include:

-

Reinforced mounting areas for sockets

-

Tight flatness and coplanarity control

-

Balanced stackup to prevent warpage

Mechanical stability directly affects contact accuracy and test repeatability.

Signal Integrity for High-Speed Testing

As test speeds increase, Test Socket PCB signal integrity becomes critical. Effective designs incorporate:

-

Controlled impedance routing

-

Short, direct signal paths

-

Proper reference planes and return paths

These measures reduce signal loss, reflections, and crosstalk at high data rates.

Power Integrity and Noise Management

Test socket PCBs must deliver clean, stable power to the DUT. Key factors include:

-

Low-impedance power planes

-

Optimized decoupling capacitor placement

-

Strong grounding to minimize noise coupling

Stable power delivery ensures accurate functional and parametric test results.

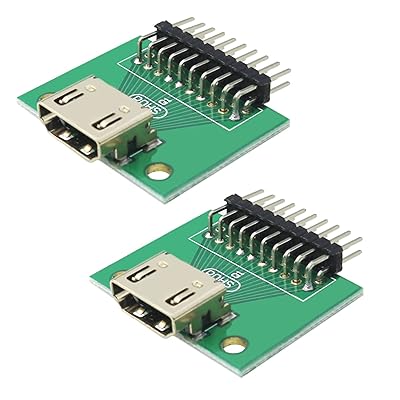

High Pin Count and Fine-Pitch Support

Modern semiconductor packages often require hundreds or thousands of pins. Test Socket PCBs must support:

-

High pin count routing

-

Fine-pitch pad and via structures

-

Multilayer and HDI PCB technologies

Precision routing is essential to maintain signal quality.

Materials and Surface Finish Selection

Material selection for Test Socket PCBs focuses on durability and electrical stability:

-

High-Tg FR-4 or low-loss materials

-

Surface finishes that support reliable contact and wear resistance

Proper material choice helps extend socket life and maintain test accuracy.

Manufacturing Precision and Quality Control

Test socket PCBs require tight manufacturing tolerances:

-

Accurate drilling and via registration

-

Consistent copper thickness

-

Electrical continuity and impedance testing

Manufacturing quality directly impacts long-term test reliability.

Typical Applications of Test Socket PCBs

Test Socket PCBs are commonly used in:

-

IC final test and production screening

-

Engineering validation (EVT/DVT)

-

Automotive and industrial semiconductor testing

-

High-speed logic, memory, and mixed-signal devices

Each application demands reliable and repeatable electrical contact.

Choosing a Test Socket PCB Manufacturing Partner

When selecting a Test Socket PCB manufacturer, key considerations include:

-

Experience with semiconductor test PCBs

-

High pin count and controlled impedance capability

-

Strong mechanical tolerance control

-

Fast response for revisions and socket changes

A reliable supplier helps ensure stable testing throughout production.

Conclusion

The Test Socket PCB is a critical interface that directly affects contact reliability, signal integrity, and overall test accuracy in semiconductor testing. By focusing on mechanical stability, electrical performance, and manufacturing consistency, a high-quality test socket PCB supports reliable, repeatable testing from validation to mass production.

Choosing an experienced Test Socket PCB supplier is essential for long-term semiconductor test success.