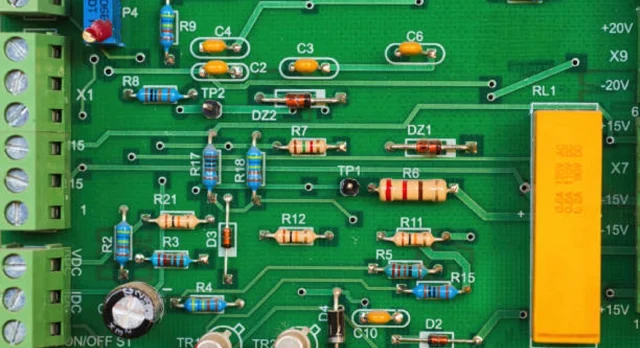

In high-volume semiconductor manufacturing, production testing must be fast, repeatable, and extremely reliable. At the center of this process is the Load Board PCB, a critical interface that connects automated test equipment (ATE) to the device under test (DUT).

A well-designed Load Board PCB ensures that every device is evaluated under identical electrical conditions, enabling stable yields and predictable test outcomes.

What Is a Load Board PCB?

A Load Board PCB is a specialized printed circuit board used in semiconductor final test and system-level test environments. It serves as the physical and electrical platform that:

-

Holds test sockets or device fixtures

-

Routes signals between ATE channels and the DUT

-

Distributes power and reference signals accurately

Unlike probe cards used at wafer level, load boards operate at the packaged-device stage and must support long-term production testing.

Why Load Board PCB Quality Matters

Poor load board performance can result in:

-

Test result variation between units

-

Increased false failures

-

Reduced throughput and yield loss

A high-quality Load Board PCB maintains consistent electrical behavior across thousands of test cycles.

Signal Integrity in High-Speed Load Board PCBs

As semiconductor test speeds continue to rise, signal integrity becomes a defining requirement. Effective load board PCB designs include:

-

Controlled impedance routing for high-speed channels

-

Length-matched signal paths

-

Proper reference plane and return path management

These features reduce reflections, crosstalk, and timing skew during testing.

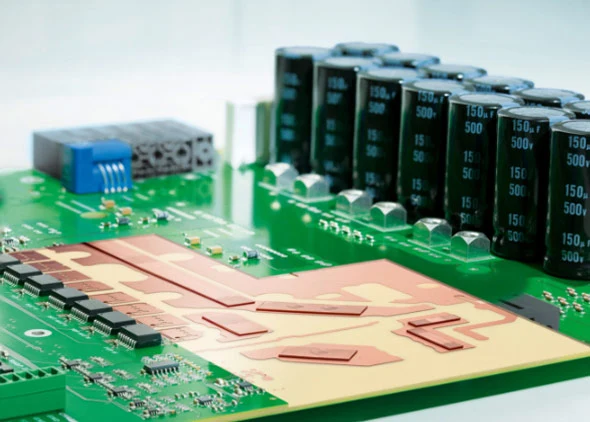

Power Integrity and Load Handling

Load boards must deliver clean, stable power to devices under test, even under rapidly changing load conditions. Key design considerations include:

-

Low-impedance power planes

-

Strategic placement of decoupling capacitors

-

Robust grounding to minimize noise

Stable power delivery is essential for accurate functional and parametric testing.

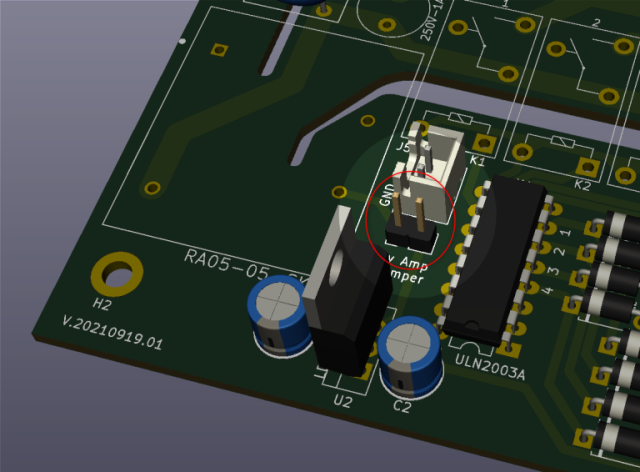

High Pin Count and Complex Interfacing

Modern ICs often require hundreds or thousands of test connections. Load Board PCBs must support:

-

High pin count routing

-

Fine-pitch socket interfaces

-

Multi-voltage and mixed-signal domains

Advanced multilayer and HDI PCB technologies are often required.

Mechanical Reliability and Durability

Load boards experience repeated socket insertions and thermal cycling. Long-term reliability depends on:

-

Excellent PCB flatness

-

Reinforced mounting and socket areas

-

Balanced stackup design to prevent warpage

Mechanical stability ensures reliable electrical contact throughout production.

Materials and Stackup Selection

Material choice for load board PCBs focuses on durability and electrical stability:

-

High-Tg FR-4 for structural integrity

-

Low-loss materials for high-speed signals

-

Hybrid stackups for mixed-frequency testing

Proper material selection ensures consistent performance over time.

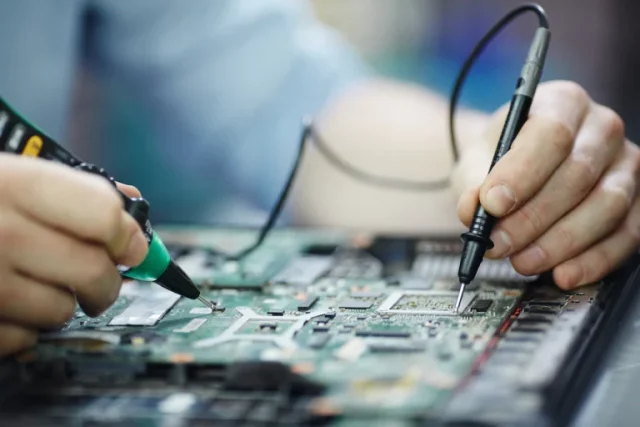

Manufacturing Consistency and Quality Control

Production load boards must deliver repeatable performance across multiple builds. This requires:

-

Tight laminate thickness control

-

Accurate drilling and via plating

-

Electrical and impedance testing

Manufacturing variation directly affects test accuracy and yield stability.

Typical Applications of Load Board PCBs

Load Board PCBs are commonly used in:

-

IC final test

-

System-level test (SLT)

-

Automotive and industrial semiconductor testing

-

High-speed logic, memory, and mixed-signal devices

Each application relies on stable, repeatable test interfaces.

Choosing a Load Board PCB Manufacturing Partner

When selecting a Load Board PCB manufacturer, consider:

-

Proven experience with semiconductor test PCBs

-

High pin count and controlled impedance capability

-

Strong process consistency and traceability

-

Fast response for design changes and revisions

A reliable supplier ensures smooth transitions from validation to mass production.

Conclusion

The Load Board PCB plays a vital role in semiconductor production testing by providing a stable, accurate, and durable interface between ATE systems and devices under test. Through careful attention to signal integrity, power stability, mechanical reliability, and manufacturing consistency, a high-quality load board PCB helps maximize yield and ensure dependable test results.

Choosing an experienced Load Board PCB supplier is essential for long-term semiconductor testing success.