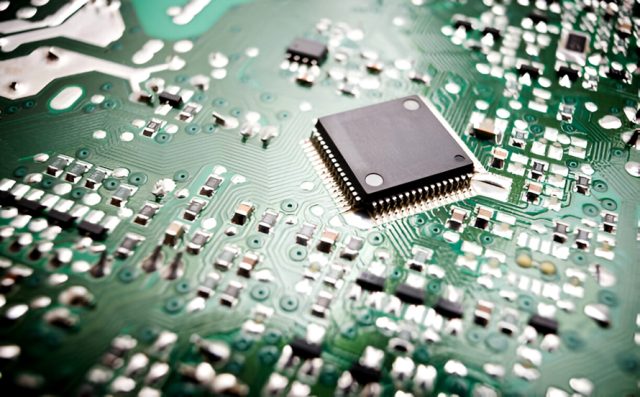

As electronic devices continue to integrate more functionality into smaller form factors, the number of signal, power, and ground connections has increased dramatically. The high pin count PCB is specifically engineered to support dense interconnect requirements while maintaining stable electrical and mechanical performance.

From semiconductor testing to high-speed communication systems, a professionally manufactured high pin count PCB is essential for reliable system operation.

What Is a High Pin Count PCB?

A high pin count PCB refers to a printed circuit board designed to accommodate a very large number of electrical connections within a limited area. These boards often feature fine-pitch components, complex routing, and multilayer stackups.

Typical characteristics include:

-

High-density routing

-

Fine line and spacing

-

Multiple signal layers

-

Precise alignment and registration

Such complexity places strict demands on both design and manufacturing processes.

Key Design Challenges of High Pin Count PCBs

Designing a high pin count PCB involves overcoming several technical challenges:

-

Routing congestion due to limited space

-

Maintaining signal integrity at high speeds

-

Managing power distribution and ground return paths

-

Controlling crosstalk and electromagnetic interference

Effective design balances electrical performance with manufacturability.

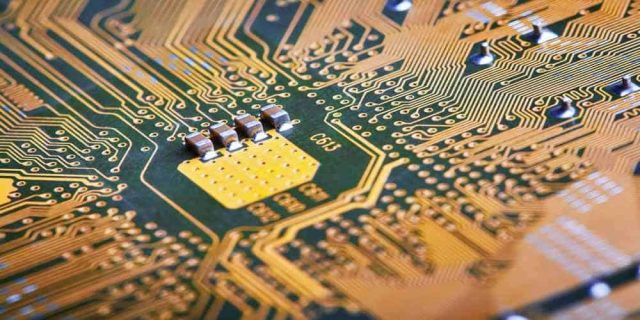

Signal Integrity in High Pin Count PCB Design

As pin count increases, signal paths become closer and more complex. High-quality high pin count PCB designs incorporate:

-

Controlled impedance routing

-

Short and balanced signal traces

-

Dedicated reference planes

-

Proper spacing between critical nets

These measures help ensure consistent and repeatable signal behavior.

HDI Technology for High Pin Count PCBs

High-density interconnect (HDI) technology is commonly used to support high pin count designs. Features include:

-

Microvias and stacked vias

-

Fine line trace routing

-

Multiple lamination cycles

HDI enables greater routing flexibility while maintaining electrical performance.

Power Integrity and Thermal Management

High pin count PCBs often support complex ICs with significant power demands. Key considerations include:

-

Low-impedance power planes

-

Effective decoupling strategies

-

Even copper distribution for thermal balance

Stable power delivery is essential for reliable operation.

Manufacturing Precision and Yield Control

Producing a reliable high pin count PCB requires advanced fabrication capabilities:

-

Tight line width and spacing control

-

Accurate layer registration

-

Consistent via drilling and plating

-

Rigorous inspection and electrical testing

Manufacturing precision directly impacts yield and long-term reliability.

Applications of High Pin Count PCBs

High pin count PCBs are widely used in:

-

Semiconductor test systems

-

High-speed networking equipment

-

5G and RF communication systems

-

Industrial and automotive electronics

Each application demands consistent performance and durability.

Choosing a High Pin Count PCB Manufacturer

When selecting a high pin count PCB manufacturer, look for:

-

Experience with HDI and fine-pitch designs

-

Controlled impedance capability

-

Proven quality management systems

-

Support from prototype to mass production

A reliable partner helps reduce risk and accelerate development.

Conclusion

The high pin count PCB is a key enabler of modern electronics, supporting dense interconnects without sacrificing signal integrity or reliability. Through advanced design techniques, HDI technology, and precision manufacturing, high pin count PCBs deliver consistent performance in demanding applications.

Choosing an experienced high pin count PCB supplier ensures higher yield, stable operation, and long-term success.