In high-volume semiconductor manufacturing, test efficiency and measurement accuracy directly affect yield and cost. Acting as the electrical bridge between automated test equipment (ATE) and packaged ICs, the load board PCB is a mission-critical component in production test environments.

A well-designed load board PCB ensures consistent signal behavior, stable power delivery, and repeatable test results across thousands of devices.

What Is a Load Board PCB?

A load board PCB is a specialized test board used in semiconductor final testing. It connects the ATE system to the device under test (DUT) through sockets, connectors, or test fixtures.

Unlike functional PCBs, load board PCBs are optimized for:

-

Electrical accuracy rather than product operation

-

High pin-count connectivity

-

Continuous test cycles in mass production

Their performance directly impacts test yield and throughput.

Why Load Board PCB Quality Is Critical

Poorly designed or manufactured load board PCBs can cause:

-

Signal loss and timing skew

-

Power instability under dynamic load

-

Crosstalk and electromagnetic interference

-

False test failures or yield loss

High-quality load board PCBs minimize these risks by maintaining stable electrical parameters over time.

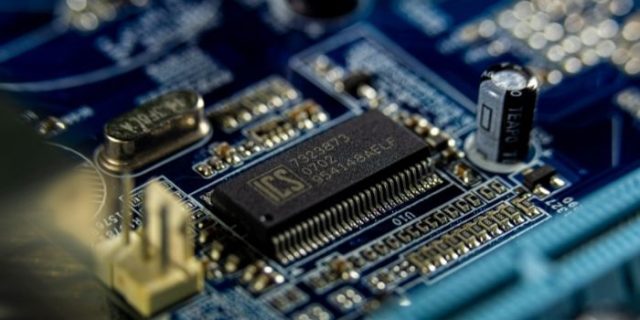

Signal Integrity in Load Board PCB Design

Modern ICs operate at high frequencies and tight margins. Effective load board PCB design includes:

-

Controlled impedance routing

-

Short, balanced signal paths

-

Dedicated reference planes

-

Isolation between high-speed and sensitive signals

These measures ensure accurate and repeatable test measurements.

Power Delivery and Current Handling

Load boards often deliver significant current to the DUT. Key considerations include:

-

Low-impedance power planes

-

Adequate copper thickness

-

Proper decoupling capacitor placement

Stable power delivery prevents voltage droop and test instability.

Thermal and Mechanical Stability

During continuous testing, load board PCBs experience thermal cycling and mechanical stress. Reliable designs focus on:

-

PCB flatness for consistent socket contact

-

Reinforced connector and socket areas

-

Materials with stable thermal properties

Mechanical reliability directly affects long-term test consistency.

Materials Used in Load Board PCBs

Common material options include:

-

High-Tg FR-4 for durability and cost efficiency

-

Low-loss laminates for high-speed testing

-

Hybrid stackups for mixed-signal environments

Material stability ensures predictable performance across temperature variations.

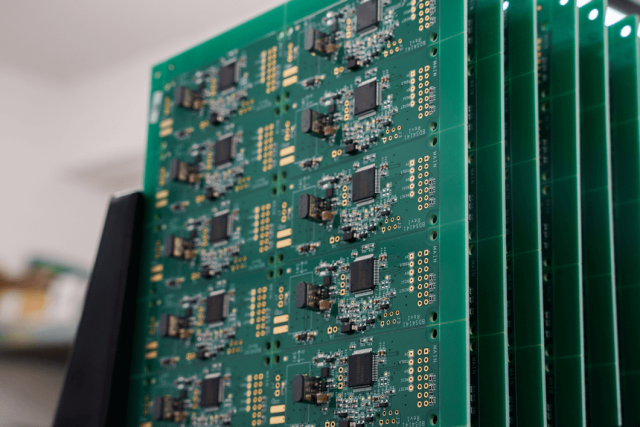

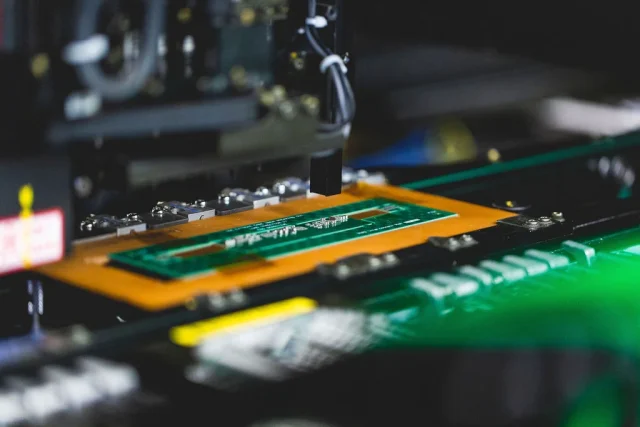

Manufacturing Precision and Consistency

Load board PCBs require tight fabrication control:

-

Accurate layer registration

-

Consistent laminate thickness

-

Uniform copper distribution

-

Reliable via plating quality

Consistency between builds is essential for standardized production testing.

Applications of Load Board PCBs

Load board PCBs are widely used in:

-

IC final test and burn-in

-

Automotive semiconductor validation

-

Power device testing

-

Consumer and industrial electronics production

Each application demands high reliability and repeatability.

Choosing a Load Board PCB Manufacturing Partner

When selecting a load board PCB manufacturer, consider:

-

Experience with semiconductor test PCBs

-

Controlled impedance and power PCB capability

-

Proven quality inspection processes

-

Support for quick-turn revisions

A reliable partner helps reduce downtime and maintain stable test performance.

Conclusion

The load board PCB is a critical component in semiconductor production testing. By delivering stable signal integrity, robust power delivery, and mechanical reliability, high-quality load board PCBs enable accurate measurements, improved yield, and efficient mass production.

Partnering with an experienced load board PCB supplier ensures consistent test results and long-term testing success.