Requesting a PCB quotation is not just a matter of sending files and asking for a price. The final cost is heavily influenced by material selection, stackup design, fabrication complexity, and testing requirements. Understanding these factors helps you submit a PCB price request that leads to an accurate, fair, and performance-optimized quote, especially for high-frequency and RF applications.

Key Factors Impacting PCB Pricing

-

Material Type

Different materials have vastly different costs:-

Standard FR-4: cost-effective, suitable for low-frequency designs

-

Rogers, PTFE, Duroid laminates: higher cost but required for RF, microwave, and high-speed PCBs

Material choice directly affects your quote and long-term signal performance.

-

-

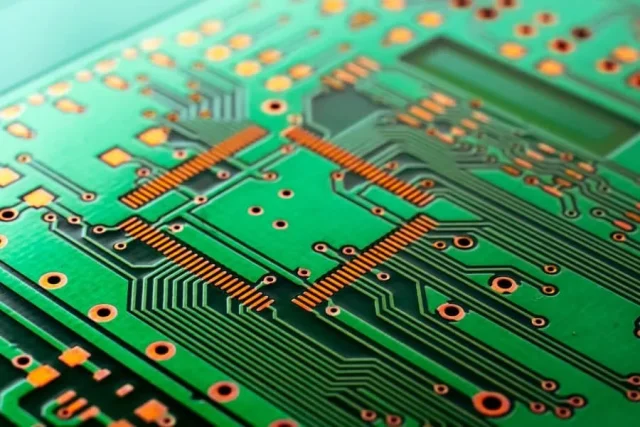

Layer Count and Stackup Complexity

-

Single or double-layer boards are simpler and cheaper

-

Multilayer and hybrid stackups increase fabrication difficulty and cost

-

Controlled impedance layers for RF/microwave add additional process requirements

-

-

Trace Geometry and Precision Requirements

-

Narrow line width and spacing increase etching complexity

-

Tight impedance tolerances (±5% or better) require advanced equipment and testing

These specifications increase manufacturing cost but are essential for signal integrity.

-

-

-

ENIG, Immersion Silver, or gold plating may be required for high-frequency boards

-

Each finish has cost and process implications

-

-

-

Electrical testing, TDR impedance validation, AOI, and X-ray inspection ensure performance

-

High-frequency PCBs often require additional RF testing, affecting the quote

-

How Early Decisions Can Optimize Cost

A well-prepared PCB price request allows manufacturers to recommend cost-effective solutions without compromising performance:

-

Selecting hybrid stackups when full high-frequency laminates are unnecessary

-

Adjusting trace width or spacing to balance cost and signal integrity

-

Consolidating layers where possible to reduce complexity

-

Choosing surface finishes based on application instead of defaulting to premium options

High-Frequency and RF PCB Considerations

For RF and high-frequency PCBs, additional factors influence the quote:

-

Dielectric constant (Dk) and dissipation factor (Df) requirements

-

mmWave performance or signal loss targets

-

Thermal and mechanical stability for automotive or aerospace applications

-

Tight tolerances for antenna or radar modules

Specifying these upfront ensures the PCB manufacturer provides a realistic, performance-based quote.

How to Submit an Effective PCB Price Request

When requesting a PCB quotation:

-

Include full design files (Gerber, drill, stackup)

-

Specify material type and performance requirements

-

Indicate layer count, surface finish, and impedance control

-

Define quantity and expected delivery timeline

-

Ask for cost breakdowns (materials, processes, testing, lead time)

This approach enables the manufacturer to provide an accurate quote and suggest optimizations.

Conclusion

Submitting a PCB price request without considering material, stackup, or process choices often leads to unexpected cost or performance compromises. For high-frequency, RF, and advanced PCBs, specifying these factors upfront allows your PCB manufacturer to deliver accurate, cost-optimized, and performance-ready quotations.

Understanding the relationship between materials, processes, and cost is essential for engineering teams, procurement, and project managers seeking both efficiency and reliability.