With the rapid development of wireless communication, automotive radar, and high-speed data transmission, the role of a reliable high frequency PCB manufacturer has become increasingly critical. High frequency PCB manufacturing demands far more than standard PCB processes—it requires deep expertise in RF materials, precision impedance control, and strict process stability.

A professional high frequency PCB manufacturer ensures signal integrity, low insertion loss, and consistent performance across RF, microwave, and high-speed electronic applications.

What Makes a Professional High Frequency PCB Manufacturer?

A qualified high frequency PCB manufacturer is defined by its ability to control electrical performance at elevated frequencies. Core competencies include:

-

Manufacturing PCBs with low-loss, high-frequency laminates

-

Precise controlled impedance PCB fabrication

-

Fine-line etching for RF and microwave traces

-

Multilayer and hybrid high frequency PCB stackups

-

Comprehensive electrical and impedance testing

These capabilities distinguish a true high frequency PCB manufacturer from general PCB suppliers.

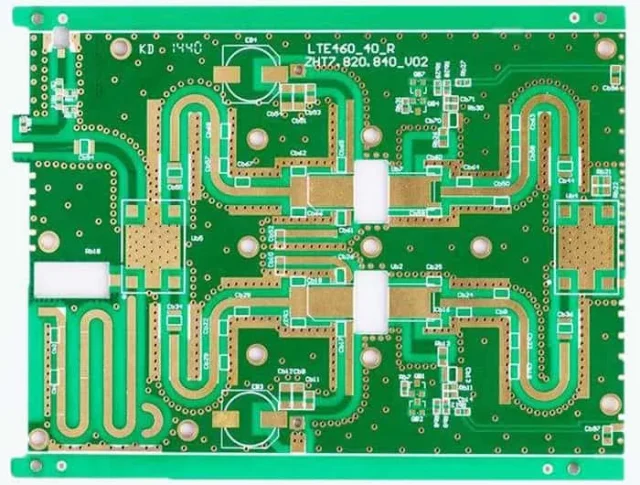

Low-Loss Materials Used by High Frequency PCB Manufacturers

Material selection is fundamental in high frequency PCB manufacturing. An experienced high frequency PCB manufacturer works with industry-proven materials such as:

-

PTFE-based and ceramic-filled laminates

-

Duroid 5880 for microwave and radar PCBs

-

Hybrid stackups combining RF materials with FR-4

Low dielectric loss and stable Dk values are essential for RF PCB and microwave PCB performance.

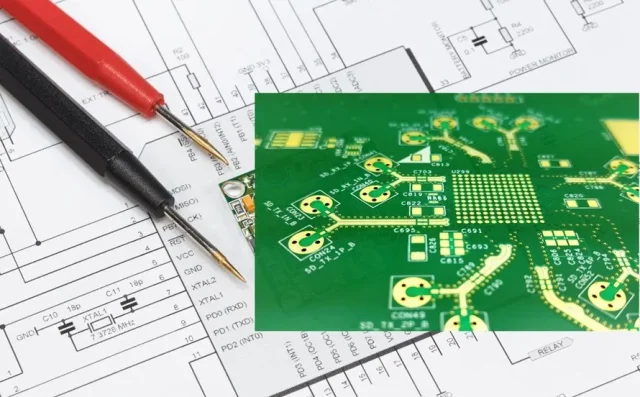

Controlled Impedance PCB Manufacturing Expertise

Controlled impedance is at the heart of high frequency PCB design. A professional high frequency PCB manufacturer provides:

-

Stackup planning and impedance calculation

-

Tight process control over dielectric thickness and copper geometry

-

Controlled impedance fabrication (±5% or tighter)

-

TDR impedance measurement and verification

Accurate impedance control reduces signal reflection, phase distortion, and transmission loss in RF and high-speed circuits.

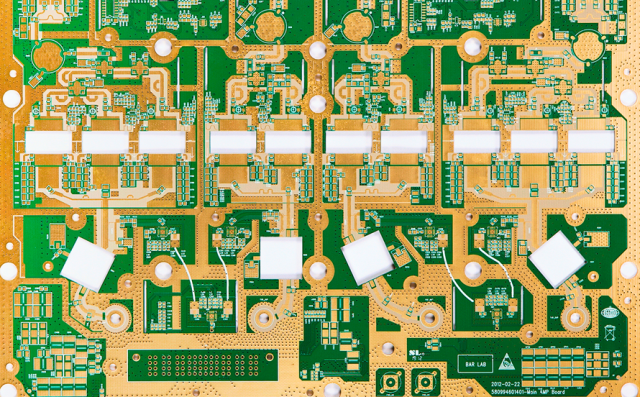

High Frequency PCB Manufacturing Capabilities

A full-service high frequency PCB manufacturer typically supports:

-

Single-layer to multilayer high frequency PCB fabrication

-

RF microstrip and stripline structures

-

HDI and microvia technology

-

RF-optimized surface finishes (ENIG, Immersion Silver, OSP)

-

Electrical testing, AOI, and X-ray inspection

These capabilities enable stable production from prototype to mass manufacturing.

Applications Served by High Frequency PCB Manufacturers

High frequency PCB manufacturers support demanding applications including:

-

RF and microwave communication systems

-

5G and mmWave RF front-end modules

-

Automotive radar and ADAS PCBs

-

High-speed networking and data center hardware

-

Industrial IoT and wireless control systems

-

Aerospace and defense electronics

Each application requires low-loss signal transmission and long-term reliability.

Why Work Directly with a High Frequency PCB Manufacturer?

Choosing a high frequency PCB manufacturer instead of a general supplier offers clear advantages:

-

Direct engineering communication

-

Faster DFM feedback and issue resolution

-

Better control of impedance and material consistency

-

Stable quality from prototype to volume production

-

Improved cost transparency and delivery reliability

A factory-direct high frequency PCB manufacturer acts as a technical partner, not just a vendor.

How to Select the Right High Frequency PCB Manufacturer

When evaluating a high frequency PCB manufacturer, consider:

-

Experience with RF, microwave, and high-speed PCBs

-

Proven controlled impedance PCB manufacturing capability

-

In-house testing and quality management systems

-

Ability to support rapid prototyping and mass production

-

Engineering support throughout the product lifecycle

The right partner ensures performance consistency and reduces development risk.

Conclusion

A professional high frequency PCB manufacturer is essential for the success of RF, microwave, and high-speed electronic systems. By combining low-loss materials, controlled impedance PCB manufacturing, and scalable production capabilities, high frequency PCB manufacturers deliver reliable performance from early prototypes to full-scale production.

Partnering with an experienced high frequency PCB manufacturer ensures superior signal integrity, stable quality, and long-term manufacturing confidence for advanced electronic designs.