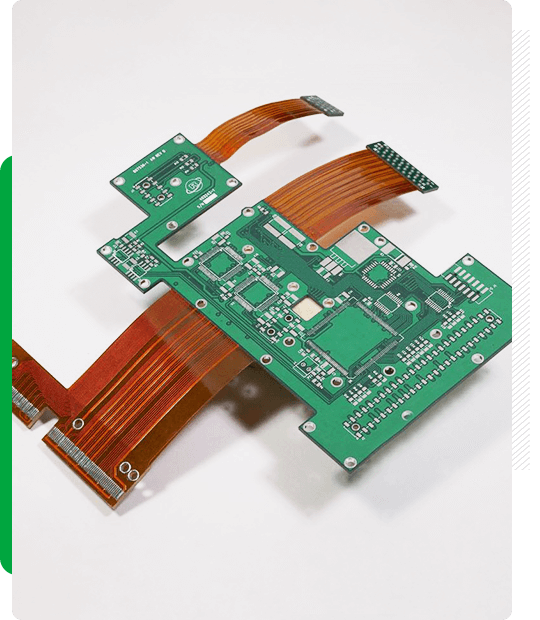

Modern electronics increasingly require compact, lightweight, and mechanically flexible designs. Multilayer rigid-flex PCB manufacturers provide integrated solutions that combine rigid PCB sections with flexible circuits, enabling reliable interconnection and high-density packaging in advanced electronic systems.

From wearable devices to aerospace and automotive electronics, multilayer rigid-flex PCBs offer durability, signal integrity, and design flexibility that conventional PCBs cannot achieve.

What Is a Multilayer Rigid-Flex PCB?

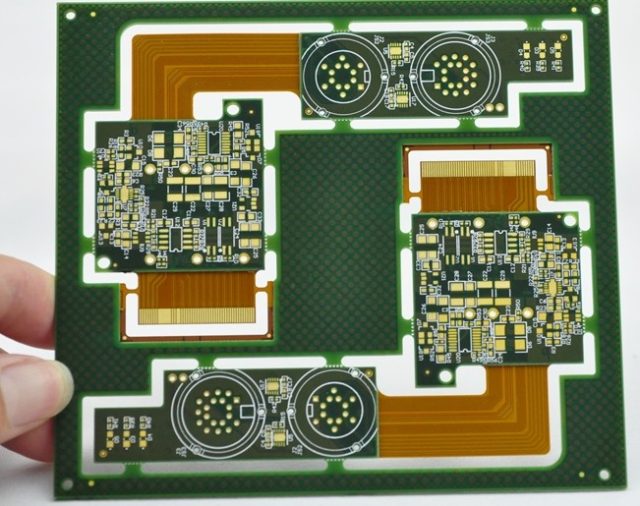

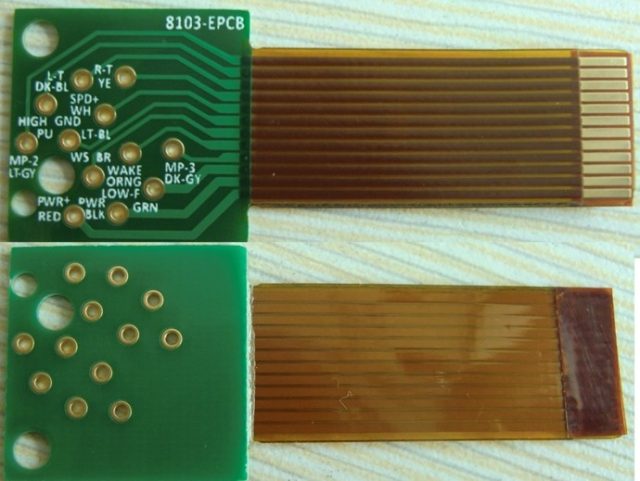

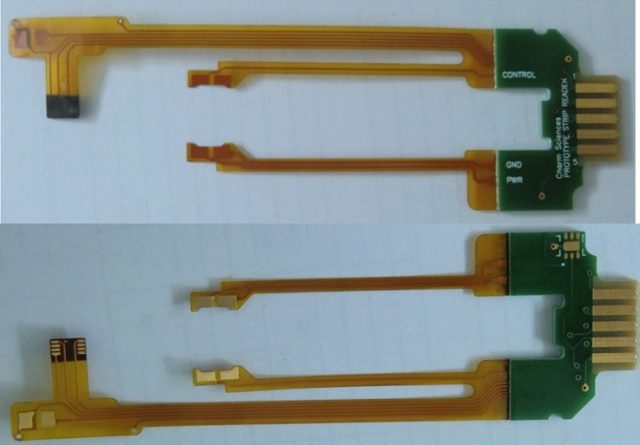

A multilayer rigid-flex PCB integrates multiple rigid layers with one or more flexible layers in a single board. Key features include:

-

High-density interconnects

-

Controlled impedance for high-speed and RF signals

-

Flexible sections for folding or bending without damage

-

Lightweight and compact form factor

These PCBs are ideal for space-constrained or dynamically moving electronic assemblies.

Advantages of Working with a Multilayer Rigid-Flex PCB Manufacturer

Compact and Lightweight Designs

Rigid-flex PCBs reduce connectors and interconnecting wires, enabling more compact assemblies.

High-Density Interconnects

Multilayer designs allow dense routing and signal separation, supporting high-speed or high-frequency applications.

Controlled Impedance and Signal Integrity

A professional manufacturer ensures precise stackup design, trace geometry, and dielectric selection to maintain signal integrity.

Mechanical Flexibility and Reliability

Flexible sections withstand repeated bending or folding, while rigid sections provide structural support.

Applications of Multilayer Rigid-Flex PCBs

Multilayer rigid-flex PCBs are widely used in:

-

Wearable devices and medical electronics

-

Aerospace and defense systems

-

Automotive electronics and advanced driver-assistance systems (ADAS)

-

Industrial automation and IoT modules

-

High-speed and high-frequency RF/microwave systems

These applications require a combination of mechanical flexibility, reliability, and high-density interconnects.

Manufacturing Considerations

A professional multilayer rigid-flex PCB manufacturer ensures:

-

Accurate stackup design and impedance control

-

Reliable lamination of rigid and flexible layers

-

Precision via drilling and plating

-

Fine-line etching and multilayer alignment

-

Electrical testing and functional verification

Advanced manufacturing capabilities guarantee durability, reliability, and repeatable performance.

Prototype to Volume Production

A qualified manufacturer supports:

-

Rapid prototyping of multilayer rigid-flex PCBs

-

Small batch pilot production

-

Large-scale mass production

-

DFM and assembly consultation

This allows seamless transition from concept to high-volume production.

Choosing the Right Multilayer Rigid-Flex PCB Manufacturer

When selecting a multilayer rigid-flex PCB manufacturer, evaluate:

-

Experience with multilayer rigid-flex designs

-

Capabilities in high-density routing and controlled impedance

-

Material expertise and RF/high-speed support

-

Prototype and volume production capacity

-

Quality management systems and testing procedures

A reliable manufacturer ensures high-quality rigid-flex PCBs that meet design, mechanical, and electrical requirements.

Conclusion

Multilayer rigid-flex PCB manufacturers provide advanced solutions for compact, flexible, and high-performance electronics. By integrating rigid and flexible sections with multilayer routing, controlled impedance, and high-density interconnects, these PCBs enable reliable, space-efficient designs across medical, automotive, aerospace, and high-speed applications.

Partnering with an experienced multilayer rigid-flex PCB manufacturer ensures your complex electronic designs are manufacturable, reliable, and scalable for production.