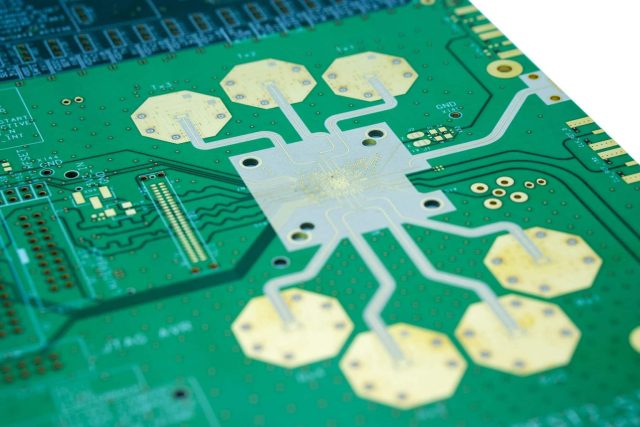

As RF, microwave, and high-speed electronic systems continue to advance, reliable PCB performance has become a key success factor. For products operating at GHz and mmWave frequencies, high frequency PCB OEM manufacturing must ensure low signal loss, stable impedance, and consistent quality across every production stage—from prototype validation to mass production.

A professional high frequency PCB OEM manufacturer provides not only fabrication services, but also engineering support, RF material expertise, and disciplined process control throughout the entire product lifecycle.

What Is High Frequency PCB OEM Manufacturing?

High frequency PCB OEM manufacturing refers to a complete manufacturing solution in which a specialized PCB manufacturer supports customers from early-stage prototypes through small batch production and full-scale mass production.

Key elements of OEM manufacturing include:

-

RF-focused engineering and DFM support

-

Material selection and stack-up optimization

-

Controlled impedance PCB fabrication

-

Quality assurance and production scalability

This OEM model ensures consistent performance and long-term supply stability.

Prototype Stage: Validating High Frequency PCB Performance

At the prototype stage, high frequency PCB OEM manufacturing focuses on design validation and risk reduction.

OEM manufacturers support:

-

Quick-turn high frequency PCB prototypes

-

Rogers, PTFE, and hybrid material processing

-

Stack-up simulation and impedance modeling

-

TDR impedance testing and RF performance checks

Rapid and accurate prototyping shortens development cycles and ensures design readiness for scaling.

Small Batch Production: Process Stability and Optimization

Once prototypes are validated, OEM manufacturing moves into small batch production.

During this phase, high frequency PCB OEM manufacturing emphasizes:

-

Process consistency and yield optimization

-

Refinement of impedance control parameters

-

Material utilization and cost optimization

-

Feedback for design and manufacturing improvement

This stage bridges R&D and mass production while minimizing technical risk.

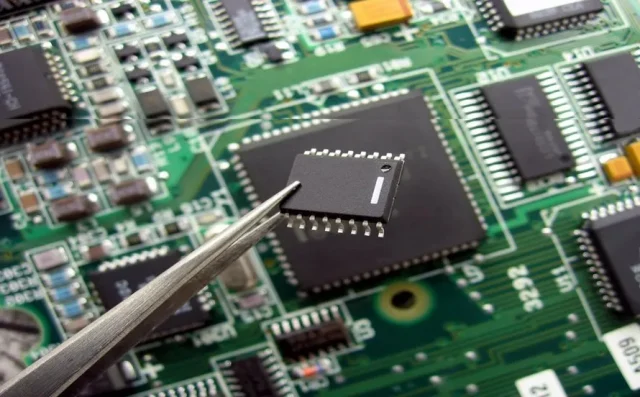

Mass Production: Scalable High Frequency PCB OEM Manufacturing

For volume manufacturing, high frequency PCB OEM manufacturers implement strict process control and quality systems to ensure repeatability.

Key capabilities include:

-

Stable multilayer and high-frequency PCB production

-

Tight tolerance control for trace geometry and dielectric thickness

-

Automated inspection and electrical testing

-

Batch-to-batch impedance consistency

Scalable OEM manufacturing ensures reliable delivery for high-volume RF and high-speed products.

RF Materials Used in High Frequency PCB OEM Manufacturing

Material selection is fundamental in high frequency PCB OEM manufacturing. Common RF materials include:

-

Rogers laminates (RO4003, RO4350, RO3003)

-

PTFE-based substrates for microwave and mmWave designs

-

Taconic RF materials such as RF-35

-

Hybrid stackups combining RF materials with FR-4

These materials provide low dielectric loss (Df) and stable dielectric constant (Dk) across frequencies.

Controlled Impedance and Signal Integrity

Accurate impedance control is a core competency of high frequency PCB OEM manufacturing.

OEM manufacturers provide:

-

Stack-up modeling and impedance calculation

-

Tight control of line width, spacing, and dielectric thickness

-

Controlled impedance fabrication (±5% or tighter)

-

TDR impedance testing with detailed reports

This ensures optimal signal integrity for RF and high-speed applications.

Quality Assurance Across the OEM Manufacturing Lifecycle

Quality assurance is integrated into every stage of high frequency PCB OEM manufacturing.

Typical QA processes include:

-

AOI and X-ray inspection

-

Electrical continuity and isolation testing

-

TDR impedance verification

-

Process traceability and reliability monitoring

Strict QA ensures long-term performance and production stability.

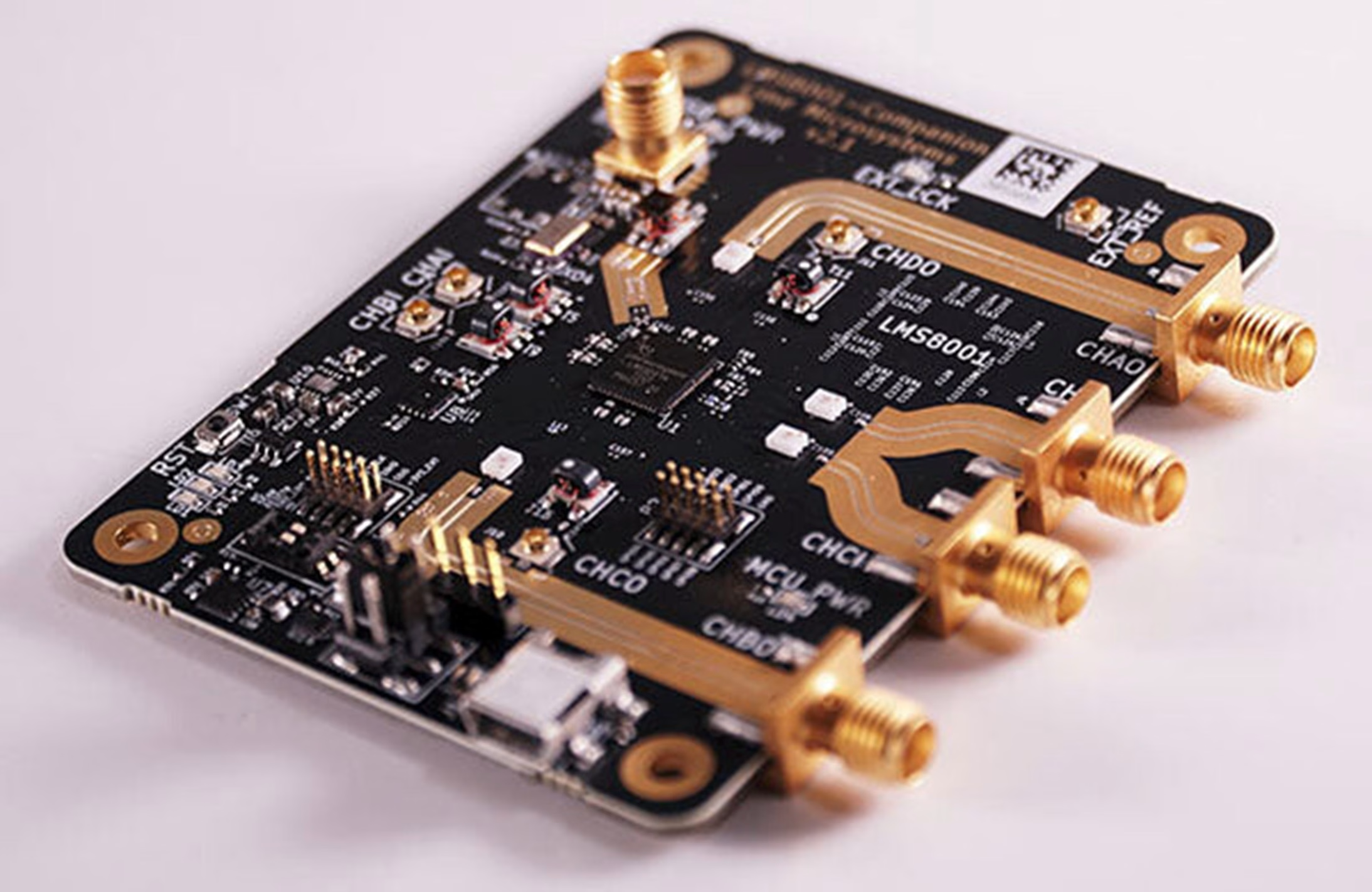

Applications Supported by High Frequency PCB OEM Manufacturing

High frequency PCB OEM manufacturing supports:

-

RF front-end and antenna modules

-

5G and wireless communication systems

-

Microwave and mmWave circuits

-

High-speed networking and data transmission equipment

-

Automotive radar and advanced sensing platforms

These applications demand low loss, stable impedance, and scalable manufacturing.

Why Choose High Frequency PCB OEM Manufacturing?

Choosing an experienced high frequency PCB OEM manufacturer provides:

-

Reduced RF and high-speed design risk

-

Faster engineering feedback and problem resolution

-

Seamless transition from prototype to mass production

-

Long-term cost control and supply reliability

OEM manufacturing partnerships accelerate time-to-market and product success.

Conclusion

High frequency PCB OEM manufacturing from prototype to mass production is essential for delivering reliable RF and high-speed electronic products. Through advanced RF materials, precise impedance control, disciplined manufacturing processes, and strict quality assurance, professional OEM manufacturers enable scalable, high-performance PCB solutions.

Partnering with an experienced high frequency PCB OEM manufacturer ensures consistent quality, faster development cycles, and reliable mass production for advanced electronic systems.