Millimeter-wave (mmWave) technologies are widely used in 5G, radar, and high-capacity wireless systems. At frequencies above 24 GHz, PCB material performance becomes a decisive factor for signal loss, phase stability, and system reliability. Taconic RF-35 PCB for mmWave applications is a proven RF laminate choice, offering low dielectric loss, excellent Dk stability, and reliable manufacturability.

Taconic RF-35 laminates are engineered to meet the strict electrical and thermal demands of mmWave circuit design.

Why Taconic RF-35 PCB Is Ideal for mmWave Applications

Taconic RF-35 PCB for mmWave designs provides several key advantages:

-

Stable dielectric constant (Dk ≈ 3.5)

-

Low dissipation factor (Df ≈ 0.0018 @ 10 GHz)

-

Excellent phase stability at high frequencies

-

Low insertion loss for mmWave signal transmission

-

Strong thermal and mechanical stability

These characteristics make RF-35 PCB well-suited for mmWave and high-frequency RF circuits.

Electrical Performance Benefits at mmWave Frequencies

At mmWave frequencies, even small dielectric variations can cause significant performance degradation. Taconic RF-35 PCB offers:

-

Consistent RF performance across wide frequency ranges

-

Reduced dielectric and conductor loss

-

Improved signal integrity for mmWave transmission

-

Reliable impedance stability under temperature variation

These benefits support high-precision mmWave circuit designs.

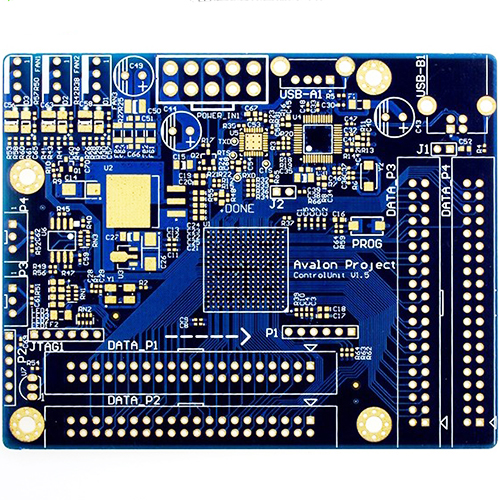

Impedance Control for Taconic RF-35 PCB

Precise impedance control is essential for mmWave performance. Taconic RF-35 PCB for mmWave fabrication supports:

-

Controlled impedance trace design

-

Accurate stack-up modeling and simulation

-

Tight line width and spacing tolerance

-

TDR impedance testing and verification

This ensures minimal signal reflection and optimized RF matching.

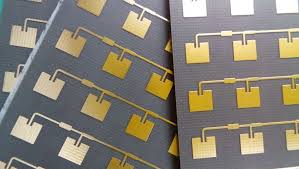

Manufacturing Considerations for RF-35 mmWave PCBs

Producing Taconic RF-35 PCB for mmWave requires specialized high-frequency PCB manufacturing expertise, including:

-

RF material-specific lamination and drilling processes

-

Copper surface roughness control to reduce conductor loss

-

Strict process stability and cleanliness control

-

RF-focused inspection and electrical testing

Experienced manufacturers ensure consistent mmWave PCB quality and yield.

Taconic RF-35 PCB vs FR-4 for mmWave Applications

| Feature | Taconic RF-35 PCB | FR-4 PCB |

|---|---|---|

| Dielectric Loss | Very Low | Very High |

| Dk Stability | Excellent | Poor |

| mmWave Suitability | Ideal | Not Suitable |

| Impedance Control | High Precision | Limited |

For mmWave designs, FR-4 is not recommended, while Taconic RF-35 PCB offers reliable RF performance.

Typical Applications of Taconic RF-35 PCB in mmWave Systems

Taconic RF-35 PCB for mmWave is widely used in:

-

5G mmWave base stations and antennas

-

Automotive radar systems

-

Satellite communication modules

-

mmWave RF front-end modules

-

High-frequency test and measurement equipment

These applications demand ultra-low loss and high-stability RF materials.

Conclusion

Selecting the right PCB material is critical for mmWave system performance. Taconic RF-35 PCB for mmWave applications provides low loss, stable dielectric properties, and reliable manufacturability, making it an excellent choice for advanced mmWave and high-frequency RF designs.

By working with an experienced high-frequency PCB manufacturer, engineers and system integrators can fully leverage the performance advantages of Taconic RF-35 PCB in demanding mmWave applications.