Rigid-Flex PCB: A Structural and Electrical Integration Platform

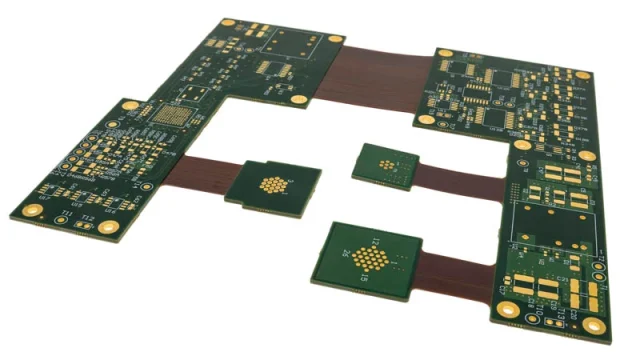

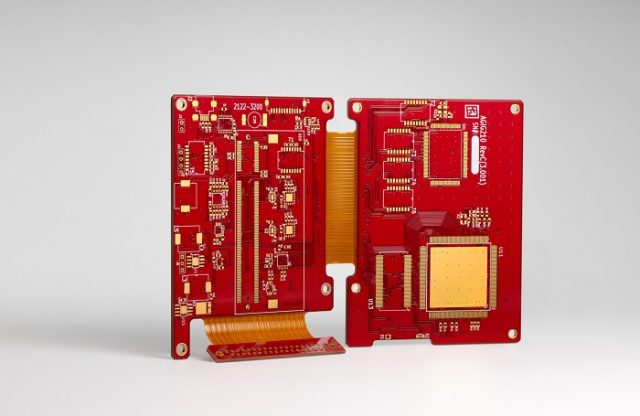

A Rigid-Flex PCB is not simply a combination of rigid boards and flexible circuits. It is a fully integrated interconnect architecture that merges rigid PCB sections with flexible PCB layers into a single, unified electrical and mechanical system. By eliminating traditional connectors and cables, Rigid-Flex PCB technology fundamentally improves reliability, signal integrity, and packaging efficiency.

In modern electronics where space constraints, vibration resistance, and signal continuity are critical, Rigid-Flex PCB designs have become a core enabler for high-end applications such as aerospace systems, medical electronics, industrial automation, robotics, and advanced consumer devices.

Why Rigid-Flex PCB Replaces Traditional Interconnect Solutions

Conventional PCB assemblies rely on connectors, cables, and soldered joints to link multiple rigid boards. These interconnect points are often the weakest link in terms of mechanical reliability and electrical stability.

A Rigid-Flex PCB eliminates these failure-prone interfaces by embedding flexible interconnect layers directly into the PCB structure. This results in:

-

Fewer solder joints and connectors

-

Higher mechanical reliability under shock and vibration

-

Reduced assembly complexity and failure rate

-

Improved signal continuity across rigid and flex sections

For high-reliability electronics, Rigid-Flex PCB architectures provide a measurable advantage over discrete rigid PCB assemblies.

Signal Integrity Advantages of Rigid-Flex PCB Designs

From an electrical perspective, Rigid-Flex PCB structures offer superior signal integrity compared to cable-based interconnects. Controlled impedance traces can be maintained seamlessly from rigid sections into flexible regions, reducing impedance discontinuities and reflection losses.

Key signal performance benefits of Rigid-Flex PCB include:

-

Stable impedance control across rigid and flex transitions

-

Reduced crosstalk and EMI compared to wire harnesses

-

Lower insertion loss for high-speed and RF signals

-

Improved phase consistency in differential pair routing

For high-speed PCB, RF PCB, and mixed-signal systems, Rigid-Flex PCB technology ensures predictable electrical behavior even in compact and mechanically dynamic environments.

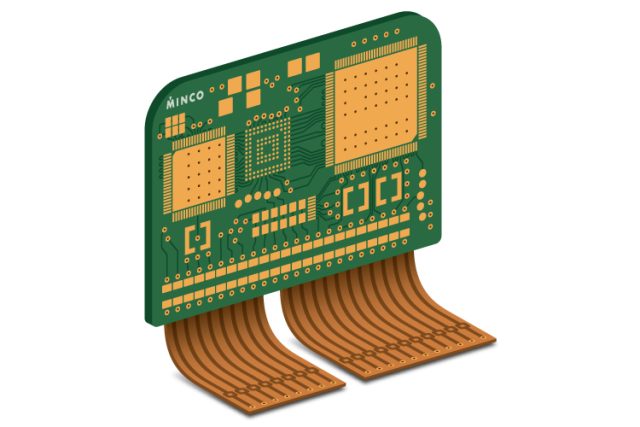

Mechanical Reliability and Dynamic Flex Performance

Mechanical stress is one of the primary failure mechanisms in compact electronics. A properly engineered Rigid-Flex PCB distributes mechanical strain across flexible polyimide layers rather than concentrating stress at solder joints or connectors.

Optimized Rigid-Flex PCB designs account for:

-

Controlled bend radius and flex layer thickness

-

Neutral axis placement to minimize copper fatigue

-

Reinforcement of rigid-flex transition zones

-

Long-cycle dynamic bending reliability

This makes Rigid-Flex PCB solutions ideal for applications requiring repeated motion, folding, or vibration resistance.

Materials and Stackup Engineering in Rigid-Flex PCB

A high-performance Rigid-Flex PCB relies on advanced material systems and precise stackup design. Typical constructions combine:

-

High-Tg FR-4 or RF laminates for rigid sections

-

Polyimide flexible substrates for flex layers

-

Adhesiveless copper-clad laminates for improved reliability

-

Coverlays and stiffeners for mechanical protection

The transition region between rigid and flex layers is carefully engineered to balance electrical continuity and mechanical durability. Stackup symmetry and copper distribution play a critical role in long-term Rigid-Flex PCB reliability.

Rigid-Flex PCB vs Rigid PCB + Connector Assemblies

When comparing system-level performance, Rigid-Flex PCB solutions consistently outperform traditional multi-board assemblies:

-

Lower total system weight

-

Reduced assembly time and cost

-

Improved shock and vibration tolerance

-

Higher signal integrity and EMI performance

Although the initial PCB fabrication cost of a Rigid-Flex PCB may be higher, the total cost of ownership is often lower due to reduced assembly, rework, and field failure risks.

Typical Applications of Rigid-Flex PCB Technology

Rigid-Flex PCB designs are widely adopted in:

-

Aerospace and avionics electronics

-

Medical imaging and implantable devices

-

Industrial automation and robotics systems

-

Automotive electronics and ADAS modules

-

Wearable and compact consumer electronics

In these applications, Rigid-Flex PCB architectures enable compact form factors without sacrificing electrical or mechanical performance.

KKPCB Rigid-Flex PCB Manufacturing Capabilities

KKPCB provides comprehensive Rigid-Flex PCB manufacturing and engineering support, covering the entire product lifecycle:

-

Multilayer Rigid-Flex PCB fabrication

-

Controlled impedance routing across rigid-flex interfaces

-

High-reliability polyimide flex processing

-

Precision drilling, laser cutting, and coverlay lamination

-

Engineering review from prototype to mass production

KKPCB’s Rigid-Flex PCB solutions are optimized for reliability, manufacturability, and electrical consistency, supporting both complex prototypes and volume production.

Conclusion

A Rigid-Flex PCB is not merely a space-saving solution—it is a system-level engineering upgrade. By integrating rigid and flexible circuitry into a single platform, Rigid-Flex PCB designs deliver superior signal integrity, mechanical reliability, and design freedom.

For advanced electronics where performance, durability, and miniaturization matter, Rigid-Flex PCB technology provides a proven and scalable interconnect solution. KKPCB supports Rigid-Flex PCB projects with deep engineering expertise and stable manufacturing quality.