High TG PCB technology has become a cornerstone for high-temperature, high-power, and long-duty-cycle electronic systems. As devices shrink, current density rises, and thermal loads increase, traditional FR-4 can no longer maintain stability. This is where High TG PCB materials—TG170, TG180, and beyond—deliver the thermal robustness and dimensional stability required for demanding environments.

High TG (Glass Transition Temperature) defines the point where PCB resin transitions from rigid to rubbery. Once a board exceeds its TG, it suffers increased expansion, degraded dielectric characteristics, and long-term reliability issues. By elevating TG, engineers gain access to superior heat resistance, lower Z-axis expansion, stronger solder-joint durability, and greater thermal cycling endurance.

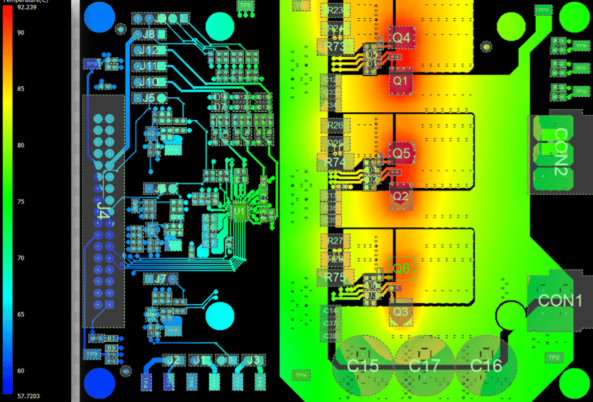

1. Thermal Stability: The Core Strength of High TG PCB

High TG PCB laminates dramatically improve high-temperature performance:

• Sustained operation at 170–180°C

• Slow thermal expansion under heavy load

• Better dimensional stability during reflow and wave soldering

• Reduced risk of pad lifting, resin cracking, and delamination

During assembly, high-power modules may experience multiple reflow cycles or operate near the thermal limit of standard FR-4. High TG PCB ensures material rigidity and dielectric stability even under repeated thermal stress.

In power electronics, automotive under-hood systems, base stations, and industrial equipment, this stability is not a luxury—it is mandatory.

2. Reliability Under High Current and Continuous Duty Cycles

High TG PCB materials are engineered for long-term reliability where standard FR-4 fails. They deliver:

• Stronger bonding strength between resin and copper

• Higher resistance to conductive anodic filament (CAF) growth

• Enhanced insulation resistance at elevated temperatures

• Improved mechanical integrity under vibration

These characteristics enable High TG PCBs to support the continuous operating cycles common in electric vehicles, servo drives, inverters, and industrial robotics.

When electronic modules run hot for thousands of hours, High TG PCB becomes a key factor preventing board deformation, micro-cracks, and electrical leakage paths.

3. Superior PTH and Via Stability for Dense Multilayer Boards

High TG PCB stackups are frequently used in:

• 8–20+ layer HDI architectures

• High-speed signal channels

• Dense BGA, FPGA, and MCU layouts

High TG resin systems reduce Z-axis expansion, protecting plated-through holes (PTH) and microvias from thermal fatigue. Multilayer PCBs used in servers, base stations, and mission-critical control boards depend heavily on this stability to prevent via barrel cracking and open circuits.

The combination of high-density layout and high-temperature operation makes High TG PCB materials crucial for long-term structural integrity.

4. Electrical Performance and Dielectric Stability

High TG laminates improve electrical reliability in high-temperature environments by maintaining:

• Stable dielectric constant (Dk)

• Low dielectric loss (Df)

• Reliable impedance control across wide temperature ranges

This is particularly important in:

• High-speed communication interfaces

• Industrial Ethernet

• Automotive ADAS modules

• 5G RF front-end circuits

Stable electrical characteristics ensure cleaner channel performance and predictable operation, even when the PCB is exposed to elevated heat for long periods.

5. Manufacturing Advantages with High TG PCB Materials

High TG PCBs improve manufacturability:

• Better process yield during multilayer lamination

• Strong resistance to thermal shock during assembly

• Lower risk of resin recession around vias and pads

• Enhanced compatibility with lead-free solder processes

Lead-free assembly runs hotter than traditional tin-lead soldering, increasing stress on PCB materials. High TG PCB minimizes deformation, ensuring consistent solder joint formation and long-term reliability.

6. Application Domains Where High TG PCB Is Essential

High TG PCB technology is widely adopted in industries where heat, power, and continuous operation converge:

• Power electronics (IGBT, SiC, DC/DC converters)

• Automotive electronics (ECU, OBC, ADAS modules)

• Industrial automation and servo drive systems

• AI computing modules and communication servers

• Aerospace and ruggedized electronics

• LED lighting power systems

Any system demanding high thermal reliability, long lifespan, and structural stability directly benefits from High TG PCB engineering.

Conclusion

High TG PCB is not just a material upgrade—it is a strategic engineering foundation for designing robust, long-life electronic systems in high-temperature and high-power environments. With superior thermal durability, mechanical stability, dielectric consistency, and manufacturing reliability, High TG PCB technology supports the next generation of automotive, industrial, power, and communication platforms.

As devices push thermal and electrical limits, High TG PCB becomes a critical enabler of long-term performance and system safety.