High-Speed PCB: Engineering Principles, Core Challenges & KKPCB Capabilities

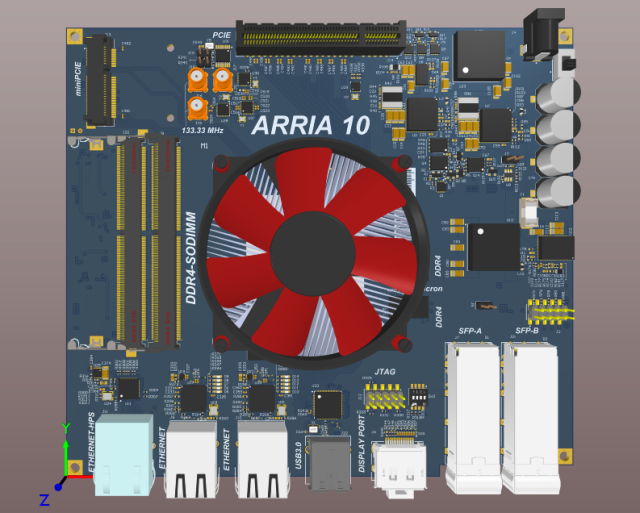

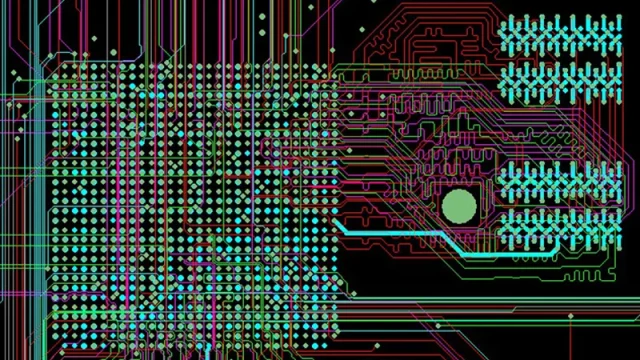

High-Speed PCB technology is at the center of every modern data-intensive system—from 5G infrastructure and AI servers to autonomous machines and aerospace communication modules. As signal frequencies climb beyond 3 GHz, 10 GHz, even 28–56 Gbps, traditional PCB design rules become insufficient. High-speed PCB engineering demands precise material selection, controlled impedance, ultra-low-loss dielectrics, optimized stackups, and strict process discipline.

Below is an enhanced, highly technical, keyword-dense article optimized for professional readers and search engines.

1. Engineering Context: What Defines a High-Speed PCB

A High-Speed PCB (High-Speed Printed Circuit Board) involves signals whose rise time, bandwidth, and frequency directly impact performance. In these systems, PCB design becomes an electrical engineering challenge—not only a mechanical layout task.

Key high-speed PCB requirements include:

-

Signal Integrity (SI) preservation across long transmission paths

-

Controlled Impedance for differential pairs (50Ω / 90Ω / 100Ω)

-

Low-Loss Material Systems (Rogers 4003C / 4350B, Megtron 6, Tachyon 100G, TU-872, F4B)

-

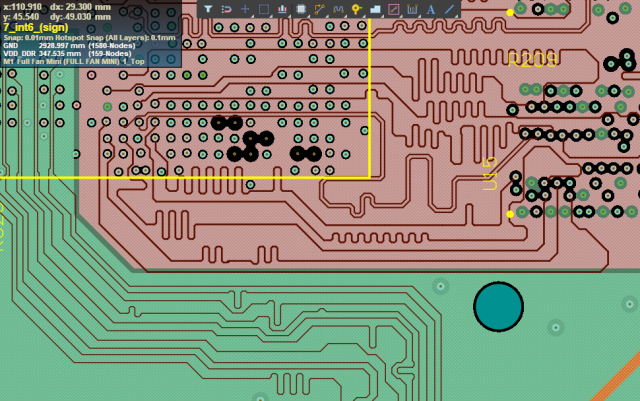

Accurate Stackup Simulation for high-speed routing

-

Skew Control, copper roughness optimization, loss tangent management

-

EMI/EMC suppression through disciplined return-path engineering

In high-frequency domains, everything matters: prepreg flow, dielectric thickness variation, trace geometry, resin content, copper foil roughness, and plating uniformity.

2. Core Engineering Challenges in High-Speed PCB

2.1 Signal Integrity Degradation

High-speed signals suffer from:

-

Insertion Loss (IL)

-

Return Loss (RL)

-

Crosstalk (NEXT/FEXT)

-

Skin Effect & Dielectric Loss

-

Mode conversion in poorly matched differential pairs

These degrade eye-diagram opening and cause timing collapse in 10–112 Gbps SerDes links.

2.2 Copper Surface Roughness & Loss Tangent

High-speed PCB performance is dominated by:

-

Dielectric loss tangent (Df)

-

Dielectric constant (Dk) stability

-

Copper roughness (Ra) affecting conductor loss

High-speed materials like Megtron 7 / Tachyon 100G / Rogers laminates deliver extremely low-loss performance compared to FR-4.

2.3 Controlled Impedance Precision

To maintain tight impedance windows (±5% or even ±3%), the PCB manufacturer must control:

-

Dielectric thickness variation

-

Copper plating thickness

-

Etching accuracy

-

Prepreg resin content

-

Lamination pressure & flow

This is why engineering-first manufacturers such as KKPCB are critical in high-speed applications.

2.4 Warpage & Stackup Asymmetry

High-speed stackups require perfect symmetry to avoid:

-

Bow and twist

-

Inner-layer misregistration

-

Via breakout

-

Differential skew imbalance

3. Material Science for High-Speed PCB

High-speed PCBs use low-loss, low-Dk, stable dielectric materials. Popular systems include:

| Material | Dk | Df | Notes |

|---|---|---|---|

| Rogers 4003C | 3.38 | 0.0027 | Stable, low-loss RF material |

| Rogers 4350B | 3.48 | 0.0037 | Excellent for RF & high-speed digital |

| Megtron 6 | 3.3 | 0.002 | Industry-leading loss performance |

| Tachyon 100G | 3.02 | 0.0021 | 100 Gbps & 56G PAM-4 systems |

| Isola I-Tera MT40 | 3.45 | 0.0031 | Good balance of cost and stability |

Material choice determines insertion loss, trace length capability, and bandwidth.

4. KKPCB High-Speed PCB Engineering Capabilities

KKPCB specializes in engineering-driven high-speed PCB manufacturing, supporting projects requiring:

-

28–112 Gbps SerDes

-

5G/6G RF Front-Ends

-

AI/Server Backplanes

-

High-Frequency Radar

-

Automotive High-Speed Networking (1000BASE-T1 / PCIe / LVDS)

Key capabilities include:

4.1 Impedance-Controlled Fabrication

-

±5% / ±3% impedance tolerance

-

Dielectric modeling based on real press-out data

-

Full stackup simulation before production

4.2 Advanced Microvia & HDI Technology

-

Laser via (1-2-3 steps HDI)

-

Stacked & staggered microvias

-

High aspect-ratio mechanical vias

4.3 Low-Loss Material Lamination Expertise

-

Rogers + FR-4 hybrid stackups

-

Megtron & Tachyon high-speed systems

-

Resin-flow-controlled lamination

4.4 High-Speed Test & Validation

-

TDR impedance testing

-

S-parameter extraction

-

Insertion-loss measurement

-

Crosstalk characterization

5. High-Speed PCB Design Guidelines

To achieve optimal performance:

-

Route differential pairs with fixed spacing and symmetry

-

Avoid stubs; use back-drilling or via-in-pad

-

Minimize layer transitions

-

Keep return paths continuous

-

Choose low-loss materials for lengths > 10 cm (at 10+ GHz)

-

Match trace lengths precisely for multi-lane SerDes

KKPCB’s engineering team provides full DFM/DFE support to help clients optimize signal integrity before production.

6. Engineering Summary

High-Speed PCB technology requires a deep understanding of high-frequency physics, advanced materials, precision fabrication, and simulation-driven stackup engineering. As data rates continue to rise, manufacturing capability—not just design—becomes a decisive factor.

KKPCB combines engineering expertise + advanced material handling + high-speed validation to deliver stable, manufacturable, and high-performance PCBs for next-generation systems.