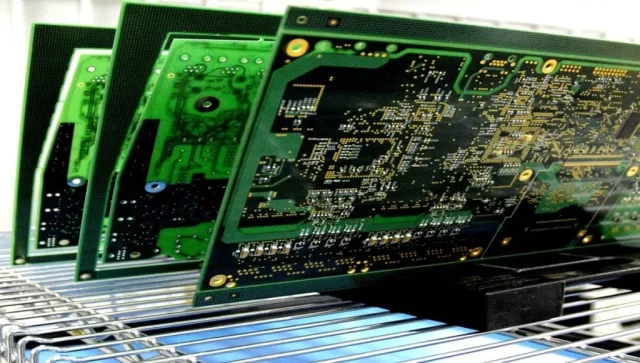

Introduction: Why Industrial Automation PCB Matters in Modern Manufacturing

As factories advance toward full digitalization, the Industrial Automation PCB becomes the central hardware platform enabling control, monitoring, power management, robotics coordination, and real-time data acquisition.

Unlike consumer electronics, an Industrial Automation PCB must operate reliably under harsh conditions—temperature extremes, vibration, electrical noise, humidity, and continuous 24/7 operation.

In smart factories, robotics clusters, and automated production lines, the Industrial Automation PCB defines system stability, safety, and operational efficiency.

1. Core Functional Requirements of an Industrial Automation PCB

Industrial systems demand uncompromising reliability. A well-designed Industrial Automation PCB must support:

-

High signal integrity for sensors, fieldbus communication, and digital control

-

Stable power distribution for drives, actuators, and PLC logic modules

-

EMI/EMC immunity for noisy industrial electrical environments

-

Long lifecycle reliability (10–20+ years of operation)

-

Robust mechanical strength for vibration-intense machinery

These characteristics ensure that an Industrial Automation PCB functions consistently in mission-critical automation systems.

2. High-Speed & High-Stability PCB Design for Industrial Communication

Industrial automation relies on deterministic high-speed communication. An Industrial Automation PCB must support:

Industrial communication protocols:

-

Ethernet/IP

-

PROFINET

-

CANbus / CAN FD

-

Modbus

-

RS-485

-

EtherCAT

-

IO-Link

Design requirements:

-

Controlled impedance routing

-

Low-noise differential pairs

-

Isolated communication channels

-

Ground partitioning between digital, analog, and power domains

A stable communication backbone is essential for every Industrial Automation PCB used in sensors, PLCs, controllers, gateways, and robotic modules.

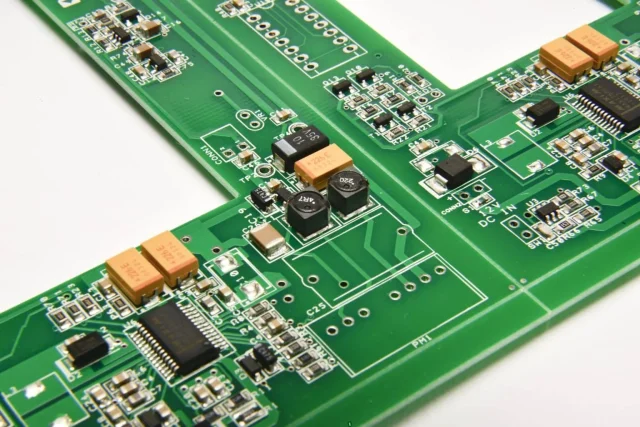

3. Power Management and High-Current Engineering in Industrial Automation PCB

Motor drives, servo systems, power stages, and solenoid actuators require carefully engineered power paths.

Power engineering for an Industrial Automation PCB:

-

Wide copper thickness (2–6 oz) for high-current capability

-

Reinforced power planes for stable distribution

-

Integrated surge and transient protection

-

Optimized PDN (Power Distribution Network)

-

Thermal relief patterns for heat stability

-

MOSFETs, IGBTs, and power modules mounted on thermally enhanced substrates

An Industrial Automation PCB must deliver consistent power even in environments with fluctuating loads and voltage spikes.

4. EMI/EMC Design for Harsh Industrial Environments

Industrial automation equipment experiences intense electromagnetic noise from motors, welders, inverters, and switching power electronics.

A robust Industrial Automation PCB requires:

-

Segregated analog and digital zones

-

Shielding and ground coupling strategies

-

Common-mode choke integration

-

RC snubbers and filter networks

-

Multi-layer stackups optimized for EMC suppression

Without proper EMI/EMC engineering, an Industrial Automation PCB risks sensor misreads, controller resets, or catastrophic system failures.

5. Environmental Durability and Long-Term Reliability

Factories expose electronics to harsh conditions:

-

High humidity

-

Wide temperature cycles

-

Chemical exposure

-

Vibrations and shock

-

Continuous operation

An Industrial Automation PCB must integrate:

-

High-Tg and high-CTI materials

-

Conformal coating or epoxy protection

-

Reinforced solder joints

-

Vibration-resistant mounting

-

Extended temperature components (–40°C to +105°C or +125°C)

Industrial Automation PCB reliability correlates directly with factory uptime.

6. Key Applications of Industrial Automation PCB

Industrial Automation PCBs are fundamental to:

Control Systems

-

PLCs

-

DCS controllers

-

Remote I/O modules

Motor & Motion Control

-

Servo drives

-

VFDs (variable frequency drives)

-

Stepper motor controllers

Robotics & Mechatronics

-

Industrial robot controllers

-

Collaborative robot electronics

-

Automated assembly systems

Sensors & Data Acquisition

-

Condition monitoring devices

-

Proximity and optical sensors

-

Smart industrial gateways

Smart Factory Infrastructure

-

Edge computing nodes

-

Industrial networking modules

-

HMI terminals

Every part of modern automation depends on high-reliability Industrial Automation PCB platforms.

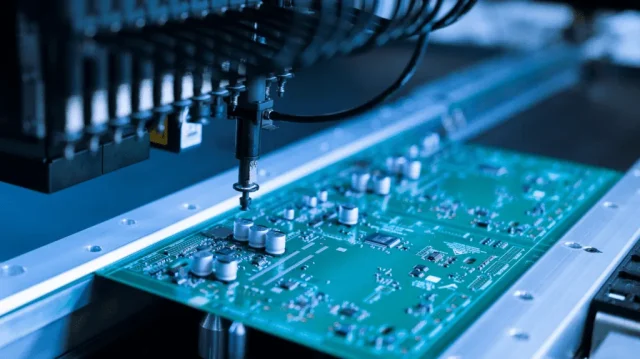

7. Why KKPCB Excels in Industrial Automation PCB Manufacturing

KKPCB specializes in engineering-grade manufacturing for Industrial Automation PCB, including:

-

High-Tg and high-temperature substrates

-

Multi-layer stackups up to 40 layers

-

Controlled impedance for industrial Ethernet

-

Thick copper power stages for drives and robotics

-

Conformal coating and ruggedization options

-

IPC Class 3 manufacturing for long-life industrial systems

Our engineering support ensures reliable performance across sensors, PLCs, industrial robots, power modules, and automation control systems.

Conclusion

Industrial Automation PCB design is a discipline that blends electrical engineering, mechanical robustness, environmental protection, and long-term reliability.

As factories advance toward Industry 4.0 and Smart Manufacturing, the Industrial Automation PCB becomes an essential foundation for real-time control, robotics, communication, and power electronics.

Companies that prioritize high-quality Industrial Automation PCBs achieve greater uptime, better process stability, and higher production efficiency—making PCB engineering a core competitive advantage in modern industrial automation.