Industrial Automation PCB engineering sits at the core of modern manufacturing, robotics, and process-control systems. In factory environments filled with electrical noise, high temperatures, continuous vibration, and mission-critical timing demands, the Industrial Automation PCB must deliver unwavering reliability, low signal distortion, and stable power delivery. As factories evolve toward smart, interconnected, high-speed architectures, the expectations placed on Industrial Automation PCBs become even stricter—higher bandwidth, lower latency, stronger EMC resilience, and guaranteed long-term durability.

This article explores the critical design principles, materials, and engineering strategies that shape next-generation Industrial Automation PCB systems.

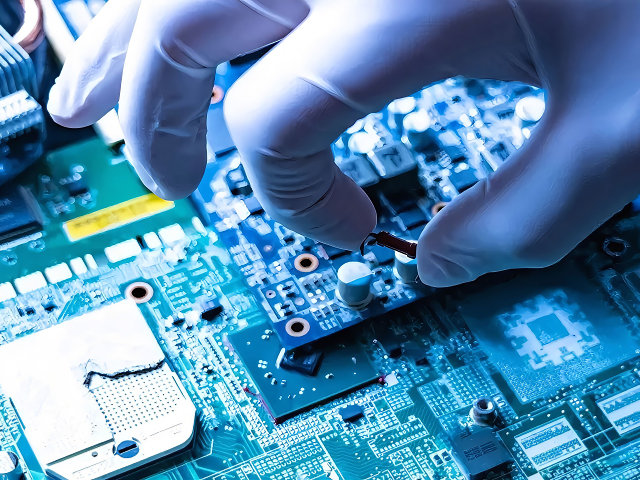

1. Reliability Engineering for Harsh Industrial Environments

Industrial automation equipment operates 24/7 under heat, vibration, humidity, and electromagnetic interference. This places extraordinary stress on the PCB.

Key reliability requirements include:

• High-TG (Glass Transition Temperature) materials to handle long operating cycles

• Improved CAF resistance to prevent electrochemical migration

• Thick copper plating (1–3 oz) for high-current motor drives and power modules

• Wide creepage/clearance distances to meet IEC and UL safety standards

• Robust solder-joint reliability for shock and vibration endurance

High-reliability automation controllers—PLCs, servo amplifiers, CNC modules, field I/O cards—depend on stable PCB structures that preserve mechanical integrity under continuous stress. The Industrial Automation PCB becomes the backbone of dependable long-term industrial performance.

2. Signal Integrity Optimization for Precision Control

Modern industrial control systems increasingly rely on high-speed signaling:

• Industrial Ethernet (EtherCAT, PROFINET, Ethernet/IP)

• High-speed encoder feedback

• Real-time motion control links

• FPGA-based control loops

To maintain low jitter, low skew, and deterministic timing, the Industrial Automation PCB integrates strict signal-integrity design:

• Controlled-impedance differential pairs

• Low-loss FR-4 or mid-loss laminates for long-distance backplanes

• Ground-referenced layer structures to suppress EMI

• Crosstalk-resistant routing for densely packed control lines

Signal integrity becomes a mission-critical factor—poor routing or impedance mismatch can degrade real-time feedback and destabilize automated processes.

3. Power Integrity and Thermal Stability for High-Current Loads

Industrial drives, power converters, robotic actuators, and inverters place heavy loads on PCB power distribution networks.

To stabilize these loads, the Industrial Automation PCB must include:

• Heavy copper layers for power stages

• Distributed decoupling networks

• Low-inductance power planes

• Thermal conductive vias and heat-spreading copper

• High-efficiency thermal paths for MOSFETs, IGBTs, and SiC/GaN devices

Thermal runaway and voltage droop are unacceptable in mission-critical automation. Power integrity design ensures stable operation even under peak current and continuous duty cycles.

4. EMC/EMI Suppression for Noise-Heavy Factory Environments

Industrial floors are saturated with:

• Motor noise

• High-current switching

• Arc discharge

• RF emissions from wireless modules

To maintain clean operation, the Industrial Automation PCB must employ aggressive EMC strategies:

• Shielded differential signaling

• Partitioned ground domains

• Line filters and ferrite structures

• Segregated analog/digital/power zones

• Multi-layer stackups engineered for field containment

Without strong EMC resilience, automation networks suffer downtime, false triggers, and dangerous instability.

5. Material Selection for Long-Life Industrial Automation PCB Systems

Material choice drives long-term stability. Industrial Automation PCBs commonly adopt:

• High-TG FR-4 (170–180°C) for thermal robustness

• Low-loss FR-4 derivatives for high-speed communication lines

• Metal-core PCB where motor heat dissipation is critical

• High-CTE stability materials for large multi-layer boards

The right material stackup ensures that the PCB retains dimensional stability across thermal cycling, vibration, and mechanical stress.

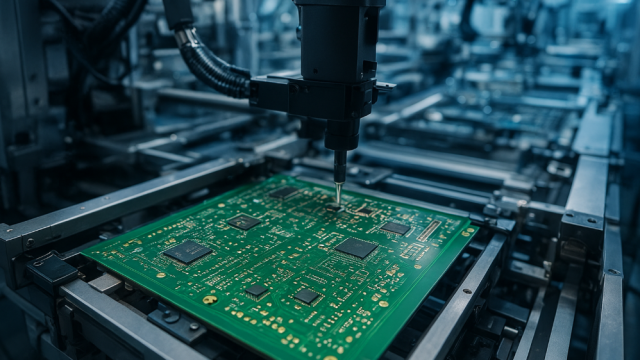

6. Advanced Manufacturing Technologies for Industrial Automation

To support modern automation architectures, PCB manufacturing incorporates:

• Fine-pitch HDI for compact control modules

• Selective thick copper areas for mixed-signal boards

• ENIG or ENEPIG finishes for long-term solder reliability

• Rigid-flex designs for robotics and articulated joints

• Automated optical and X-ray inspection for zero-defect delivery

Automation engineering demands consistency—not only in design, but in fabrication and quality assurance.

Conclusion

Industrial Automation PCB engineering is evolving into a discipline that blends high-speed data transmission, noise immunity, rugged mechanical stability, and power-dense thermal management. As factories adopt robotics, AI-driven control, and real-time industrial networking, the Industrial Automation PCB becomes more essential than ever—serving as the electrical, thermal, and communication foundation of smart manufacturing.

This field continues to expand into deeper materials science, advanced stackup architectures, and precision signal-integrity engineering. Each new development pushes Industrial Automation PCB technology closer to the ultra-reliable, high-performance infrastructure required for next-generation automated systems.