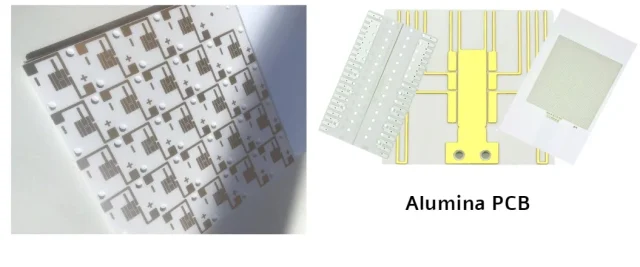

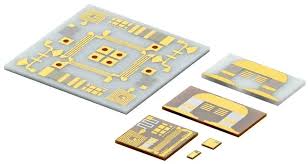

Alumina PCB substrates have become a cornerstone technology for next-generation power electronics, especially in systems where thermal conductivity, electrical insulation strength, and long-term environmental stability directly define system reliability. As power densities continue to rise in EV inverters, industrial motor drives, renewable-energy converters, and high-voltage power supplies, engineers are increasingly replacing traditional FR-4 and metal-core PCB (MCPCB) platforms with 96%–99.6% alumina ceramic PCBs to obtain superior thermal, dielectric, and mechanical performance.

1. High Thermal Conductivity for Dense Power Designs

Alumina ceramics deliver a thermal conductivity of 20–30 W/m·K, significantly outperforming conventional epoxy-glass laminates and even some aluminum-based MCPCBs. This high thermal flux capability enables efficient heat spreading from MOSFETs, GaN FETs, silicon carbide (SiC) devices, rectifiers, and power modules operating at elevated junction temperatures.

The combination of thick-film or DBC (Direct Bonded Copper) metallization with alumina substrates supports:

• Lower junction-to-case thermal resistance

• Higher continuous current handling

• Improved derating margins under transient loads

• Stable thermal behavior at 150–250°C operating ranges

For applications like EV onboard chargers, IGBT gate drivers, and high-frequency resonant converters, the predictable thermal performance of alumina PCBs directly enhances device lifespan and module-level MTBF.

2. Superior Dielectric Strength and High-Voltage Isolation

A defining advantage of alumina PCB substrates is their 10–20 kV/mm dielectric strength, making them ideal for high-voltage insulation in compact designs. Power modules can integrate high-voltage switching paths and low-voltage control circuits on the same substrate while maintaining strict creepage and clearance requirements.

This high isolation capability benefits:

• High-voltage auxiliary power supplies

• Flyback and LLC converters

• High-voltage battery protection circuitry

• Industrial automation drives and servo systems

• Photovoltaic string inverters and HV DC-link units

Compared to organic-based laminates, alumina maintains insulation reliability even in high-humidity, high-temperature, and high-frequency switching conditions.

3. Long-Term Stability in Harsh Power Environments

Alumina PCBs provide exceptional chemical resistance, moisture stability, and mechanical durability. They do not absorb moisture, do not deform under thermal cycling, and resist substrate carbonization under high dV/dt switching.

This stability supports the increasing adoption of SiC-based power electronics, where switching edges, thermal oscillations, and electromagnetic stresses significantly exceed the tolerance of conventional PCB materials.

Key reliability benefits include:

• Stable dielectric constant (εr ≈ 9.8) across wide temperatures

• Low loss tangent suitable for high-frequency power control

• Resistance to oxidation and chemical corrosion

• Excellent mechanical strength under vibration and shock

4. Metallization Options for High-Power Interconnects

Alumina PCBs support a variety of conductor systems:

• DBC (Direct Bonded Copper) for high-current modules

• DPC (Direct Plated Copper) for fine-line high-density designs

• Thick-film silver/palladium for precision hybrid circuits

• ENIG or ENEPIG surface finishes for wire bonding and component mounting

This flexibility allows designers to build hybrid structures combining power components, gate drivers, sensor interfaces, and RF elements on the same ceramic board.

5. Applications Accelerating Alumina PCB Adoption

Alumina ceramic substrates are now widely used in:

• EV powertrains and high-voltage battery modules

• SiC/GaN-based high-frequency converters

• Aerospace and defense high-voltage controllers

• Industrial automation power control modules

• Medical high-voltage imaging systems

• LED lighting engines with elevated thermal loads

The combination of thermal conductivity, insulation strength, and environmental resilience positions alumina PCBs as an enabling substrate for the next generation of compact, high-efficiency, high-voltage power electronics.