High-speed communication modules in 5G, satellite transceivers, and high-frequency computing systems demand extreme precision in signal routing and interconnect integrity. As layer density increases and modules become more compact, traditional through-hole vias introduce unwanted parasitic effects, signal reflection, and EMI interference, compromising both channel fidelity and system performance.

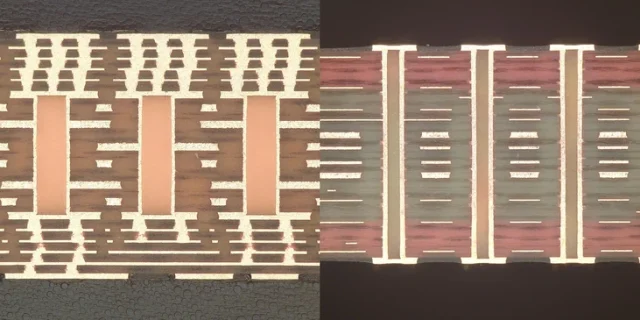

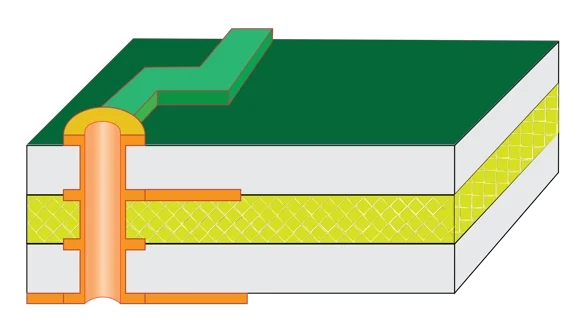

Blind via PCB technology enables selective inter-layer connections without penetrating the full stackup, reducing via parasitics, insertion loss, and crosstalk. KKPCB combines precision drilling, controlled copper plating, and optimized dielectric stackups to deliver phase-stable, low-loss multilayer PCBs capable of supporting mmWave and multi-Gigabit high-speed signals.

Key Engineering Challenges

| Challenge | Root Cause | Engineering Impact |

|---|---|---|

| Signal reflection & impedance drift | Excessive via stub length, dielectric mismatch | Phase errors, signal integrity loss |

| Crosstalk between dense RF channels | High-density trace routing, improper shielding | Reduced SNR, waveform distortion |

| High insertion loss | Surface roughness, dielectric dissipation | Lower RF output power, reduced link margin |

| Thermal-induced via stress | CTE mismatch, high RF power | Microvia cracking, long-term reliability issues |

| Manufacturing tolerance | Drill misalignment, plating variation | Inconsistent electrical performance across boards |

Material Science & Blind Via PCB Advantages

| Parameter | Typical Value | Engineering Benefit |

|---|---|---|

| Dielectric Constant (Dk) | 3.48 ± 0.03 | Stable impedance for high-frequency multilayer routing |

| Dissipation Factor (Df) | 0.0035 @10 GHz | Low-loss signal propagation across blind via interconnects |

| Thermal Conductivity | 0.62 W/m·K | Reduces hotspot formation and improves RF power handling |

| Coefficient of Thermal Expansion (CTE) | 16 ppm/°C | Minimizes mechanical stress on blind vias |

| Via Aspect Ratio | ≤1:1 | Ensures robust plating and long-term via reliability |

Blind via PCBs enhance multilayer routing density while maintaining phase integrity, EMI suppression, and impedance control, critical for high-speed RF and mmWave modules.

KKPCB Case Study — High-Speed 5G Communication Module

Client Requirements:

A 5G transceiver module required 10-layer blind via PCB supporting multiple mmWave channels (24–40 GHz) with phase deviation <0.5°, insertion loss <0.35 dB/in, and strict EMI constraints in a compact footprint. Conventional through-hole vias caused excessive signal reflection and channel crosstalk.

KKPCB Engineering Solution:

-

Optimized blind via placement and aspect ratio for minimal parasitic effects

-

Smooth copper plating (Ra <0.6 µm) to reduce RF insertion loss

-

Shielded ground planes and via stitching to suppress EMI

-

±3 µm dielectric thickness tolerance for tight impedance control

-

Inline TDR & HFSS simulation to verify phase linearity across all RF channels

Performance Results:

| Parameter | Target | Achieved |

|---|---|---|

| Insertion Loss @28 GHz | <0.35 dB/in | 0.32 dB/in |

| Phase Deviation | <0.5° | 0.43° |

| Crosstalk Reduction | >25% | 30% |

| Impedance Variation | ±3% | ±1.5% |

| Thermal & Mechanical Reliability | 1000 cycles | Passed |

Stackup Design & RF Validation

-

HFSS Modeling: Fine-tuned microstrip/stripline impedance and reduced interlayer coupling

-

ADS & TDR: Verified phase stability <0.5° across all channels

-

Thermal FEM: Controlled hotspots and confirmed via mechanical stress tolerance

-

AOI & Solder Reflow Monitoring: Maintained ±10 µm alignment across layers

Environmental & Reliability Testing

| Test | Condition | Result |

|---|---|---|

| Thermal Cycling | –40°C ↔ +125°C, 1000 cycles | No delamination, phase deviation <0.5° |

| Vibration & Shock | 5–500 Hz, 10G | No microvia cracking |

| Humidity Exposure | 85°C / 85% RH, 1000 h | Dk/Df stable, EMI reduction maintained |

| Continuous mmWave RF Test | 28–40 GHz | Minimal insertion loss (<0.02 dB) |

| Solder Reflow | 260°C ×3 cycles | Stackup alignment preserved |

Engineering Summary & Contact

Blind via PCB technology enables high-density, low-loss RF routing with precise impedance control and EMI suppression for advanced communication modules. KKPCB’s expertise in multilayer blind via design, precision lamination, and high-frequency RF verification ensures phase-stable, mmWave-capable PCBs with long-term reliability under thermal and mechanical stress.

Contact KKPCB Engineering Team for consulting on blind via stackups, multilayer RF simulation, and high-frequency PCB optimization for next-generation high-speed modules.