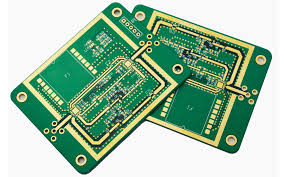

What Is ENIG PCB Surface Finish?

What Is ENIG in PCB Manufacturing?

ENIG (Electroless Nickel Immersion Gold) is one of the most widely used and highly reliable PCB surface finishes in the electronics industry. As a chemical deposition process, ENIG forms a two-layer metallic coating—a nickel barrier layer followed by a thin immersion gold layer—without applying electrical current.

Typical coating thickness:

-

Nickel (Ni): 3–6 μm (0.05–0.2 μm in some simplified texts, but industry standard is 3–6 μm)

-

Gold (Au): 0.05–0.15 μm

The nickel layer prevents copper diffusion and provides structural strength, while the gold layer ensures long-term solderability and oxidation resistance.

Because ENIG provides a flat, durable, and corrosion-resistant surface, it has become the preferred finish for high-reliability PCBs in aerospace, medical, military, industrial, and communication systems.

Why PCB Surface Finishes Matter

PCB surface finishes protect exposed copper pads from oxidation and enable consistent solderability during assembly. Without the proper finish, copper would oxidize rapidly, leading to:

-

Poor solder joints

-

Increased electrical resistance

-

Reliability failures

ENIG stands out due to its balance of solderability, wire-bond compatibility, and environmental robustness.

How the ENIG Coating Process Works

The ENIG process involves multiple chemical stages to ensure adhesion, durability, and consistent thickness.

1. Cleaning

Removes oils, oxidation, fingerprints, and residue using mechanical scrubbing + chemical cleaning.

2. Micro-etching

Lightly etches copper to improve adhesion by creating a micro-roughened surface.

3. Electroless Nickel Deposition

A controlled autocatalytic reaction deposits a uniform nickel layer onto exposed copper.

Function:

-

Diffusion barrier

-

Foundation for immersion gold

-

Provides mechanical strength and wear resistance

4. Rinsing

Removes excess nickel chemicals to prevent contamination.

5. Immersion Gold Deposition

Gold ions displace nickel atoms, creating a thin, highly stable gold layer.

Function:

-

Oxidation protection

-

Solderability

-

Wire bonding compatibility

6. Final Rinse & Drying

Ensures a clean surface and prepares the board for inspection.

7. Inspection

Checks for:

-

Coating uniformity

-

Porosity

-

Nickel corrosion (Black Pad risk)

Advantages of ENIG Surface Finish

1. Excellent Corrosion Resistance

The nickel layer protects copper from oxidation and chemical attack. Ideal for harsh environments.

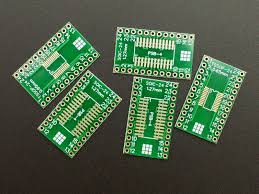

2. Extremely Flat Surface

Perfect for:

-

BGA packages

-

Fine-pitch components

-

Chip-scale packages (CSPs)

-

High-density mounting

3. Superior Wire Bonding

ENIG is compatible with aluminum and gold wire bond technologies.

4. Great Solderability & Long Shelf Life

ENIG surfaces maintain solderability for 12+ months, far superior to OSP or HASL.

5. RoHS-Compliant

No lead is used in the finish, meeting global environmental standards.

6. Suitable for Multiple Reflow Cycles

Gold layer maintains stability despite multiple heating cycles.

Disadvantages of ENIG

1. Higher Cost

Gold and the multi-step chemical process make ENIG more expensive than HASL or OSP.

2. Sensitive to Handling

Nickel can oxidize if improperly handled during manufacturing.

3. Risk of “Black Pad” Defect

Excessive nickel corrosion can cause solder joint fractures.

4. Limited Thermal Shock Resistance

Rapid temperature changes may crack the nickel-gold interface.

5. Not Ideal for Ultra-High-Temperature Applications

Intermetallic breakdown can occur above recommended limits.

Applications of ENIG Surface Finish

1. Electronics & Consumer Devices

-

Smartphones

-

Laptops

-

Wearables

-

High-density SMT assemblies

ENIG’s flatness is ideal for modern miniaturized components.

2. Medical Electronics

Devices requiring long-term stability:

-

Pacemakers

-

Heart monitors

-

Diagnostic instruments

3. Aerospace & Defense

Harsh operating environments and mission-critical performance demand high reliability.

4. Telecommunications

Used in:

-

High-speed routers

-

Servers

-

Base stations

ENIG’s uniformity supports high-frequency signal integrity.

5. Automotive Electronics

Critical systems such as:

-

ECUs

-

ADAS modules

-

Airbag controllers

ENIG withstands vibration, humidity, and moderate thermal stress.

Conclusion

ENIG (Electroless Nickel Immersion Gold) remains one of the most trusted PCB surface finishes across high-reliability industries. It delivers exceptional corrosion resistance, solderability, flatness, and compatibility with fine-pitch components and wire bonding processes. Although ENIG costs more and requires careful process control, its performance advantages make it the go-to solution for aerospace, medical, telecom, defense, and advanced consumer electronics.