Microwave Module PCB: Precision Engineering for High-Frequency Excellence at KKPCB

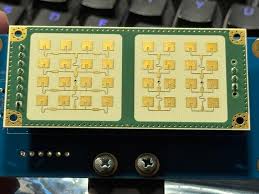

As wireless systems enter the microwave and millimeter-wave domain—from 2 GHz radar to 30 GHz satellite links and even 77 GHz ADAS—the role of the Microwave Module PCB becomes mission-critical. These PCBs are no longer just interconnect structures; they function as precision RF substrates, thermal platforms, and electromagnetic components that directly shape system performance.

At KKPCB, we combine advanced materials, high-frequency manufacturing technologies, and RF-driven engineering methodologies to deliver microwave module PCBs capable of meeting the stringent demands of radar, aerospace, 5G infrastructure, defense electronics, and satellite communication systems.

This article explores the engineering principles behind microwave module PCBs and how KKPCB builds industry-leading solutions that maximize signal integrity, stability, and reliability at multi-GHz frequencies.

1. What Is a Microwave Module PCB?

A Microwave Module PCB is a specialized circuit board engineered to operate within:

-

Microwave frequencies: 2 GHz – 30 GHz

-

Millimeter-wave frequencies: 30 GHz – 80 GHz

Unlike standard PCBs, microwave module PCBs must maintain:

- Ultra-low insertion loss

- Precise impedance control (±5% or better)

- Stable dielectric properties across wide temperature ranges

- Minimal conductor surface roughness

- Robust RF grounding through microvias and stitching vias

- Excellent thermal performance for power amplifiers (PA/LNA)

These PCBs often integrate RF front-ends, antennas, mixers, PAs, filters, phase shifters, and waveguide transitions into a single compact module.

2. Why Microwave Module PCBs Require Specialized Materials

At microwave frequencies, material properties determine the entire system’s success.

KKPCB utilizes premium high-frequency materials:

PTFE Laminates (e.g., Rogers RT/duroid® 5880, 6002, 6035HTC)

-

Ultra-low Df (0.0009–0.002)

-

Ideal for 24–77 GHz radar and satellite links

Ceramic-Filled Hydrocarbon Laminates (RO4350B, RO4003C, RO4835)

-

Easier processing than pure PTFE

-

Excellent stability at 6–30 GHz

Woven Glass PTFE (Taconic TLY/TL Series)

-

Very low moisture absorption

-

Consistent dielectric properties for beamforming networks

Metal-Backed Laminates

-

Optimized for high-power microwave PAs

-

Provides superior heat dissipation

KKPCB maintains strategic inventory to guarantee fast production cycles and consistent performance.

3. Key Engineering Principles for Microwave Module PCB Design

Microwave PCB design requires deep understanding of RF physics, electromagnetic propagation, material science, and thermal behavior.

(1)Transmission Line Structures

Microwave modules commonly use:

-

Microstrip

-

Stripline

-

Grounded Coplanar Waveguide (GCPW)

-

Suspended stripline

-

Slotline / waveguide transitions

KKPCB ensures line-width tolerance as low as ±0.001″, essential for maintaining 50 Ω impedance at multi-GHz frequencies.

(2)Low-Loss Routing Techniques

To minimize insertion loss:

-

Avoid right-angle bends → use smooth curvature

-

Maintain continuous ground reference planes

-

Use via fences for RF isolation

-

Shorten high-frequency paths

-

Select low-Ra rolled copper for reduced conductor loss

(3) RF Shielding and Isolation

Microwave modules often integrate:

-

PA

-

LNA

-

Filters

-

Mixers

-

LO routing

-

Phase shifters

Isolation is achieved via:

-

Metal cavities

-

Via stitching walls

-

Partitioned ground planes

-

Shield cans

KKPCB supports CNC-cut RF cavities and precision-milled housings for hybrid MIC/MMIC modules.

(4)Thermal Management for Power Devices

Microwave PAs generate significant heat. KKPCB implements:

-

Metal-backed substrates

-

Heavy copper under PA regions

-

Dense thermal via arrays

-

Microvia-in-pad for efficient vertical heat transfer

Thermal stability directly impacts gain, noise figure, and frequency response.

(5)Tight Dimensional Control

Microwave performance depends heavily on geometrical precision.

KKPCB uses:

-

Laser Direct Imaging (LDI) for sub-50 µm accuracy

-

Laser drilling for clean PTFE holes

-

Plasma etching to prepare PTFE vias

-

Precision dicing for edge plating and castellations

4. Hybrid Microwave Modules: Where RF and Digital Worlds Meet

Modern microwave modules often combine:

-

RF front-end (PTFE, low Dk)

-

Digital control logic (FR-4 or low-loss FR-4)

-

High-speed baseband (Megtron 6/7)

KKPCB excels in complex hybrid stackups featuring:

-

Sequential lamination

-

Mixed dielectric systems

-

Embedded passive components

-

Controlled CTE matching

Ideal for:

-

5G transceivers

-

Phased-array beamforming modules

-

Radar front-end modules (24 GHz / 77 GHz)

-

Satellite modems and RFIC packaging

5. Manufacturing Technologies That Set KKPCB Apart

KKPCB integrates advanced processes not found in standard PCB factories.

High-Frequency Fabrication Equipment

-

LDI exposure for precision imaging

-

Plasma treatment for PTFE via metallization

-

Laser microvia drilling

-

High-precision CNC for RF cavities

-

ENEPIG and soft-gold finishes for wire bonding

RF-Specific Capabilities

-

Edge plating / castellated holes

-

Embedded filters

-

Cavity PCBs

-

Via-in-pad microvias

-

GCPW with controlled impedance

-

Sub-0.002″ registration accuracy

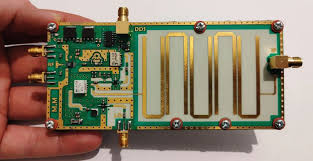

Mechanical-RF Integration

3-axis, 4-axis, and 5-axis CNC machining allows:

-

Integrated waveguide channels

-

RF shielding structures

-

Metal-backed module housings

-

Hybrid MIC/MMIC packaging

6. Applications of Microwave Module PCBs

Aerospace & Satellite

-

Ka/Ku/X-band transceivers

-

VSAT modems

-

Phased-array radars

Automotive

-

24 GHz/77 GHz ADAS radar modules

-

Short-range radar (SRR)

-

Antenna-in-package boards

5G & mmWave

-

Beamforming modules

-

Remote radio units

-

Backhaul microwave radios

Defense & Security

-

Electronic warfare (EW) modules

-

Guidance radar electronics

-

Secure communication systems

Instrumentation

-

Spectrum analyzers

-

Network analyzers

-

High-frequency signal generators

KKPCB serves industries requiring the highest level of RF precision and reliability.

7. Why KKPCB Is the Trusted Partner for Microwave Module PCBs

-

Large in-house inventory of microwave materials

-

Full-stack manufacturing from PCB to CNC housings

-

Industry-leading accuracy in RF geometries

-

Expertise in PTFE and hybrid stackups

-

IPC Class 3, ISO 9001, IATF 16949 certifications

-

Proven quality in aerospace, automotive radar, satellite & defense applications

With decades of RF engineering and high-frequency manufacturing experience, KKPCB delivers microwave module PCBs that consistently exceed performance expectations.