Small Batch ATE PCB manufacturing is designed to support semiconductor and automated test equipment (ATE) applications that require low-volume production with high performance and reliability. Unlike mass production PCBs, small batch ATE PCBs are typically used for engineering validation, system qualification, pilot runs, and customized test solutions.

As test requirements continue to evolve rapidly, small batch ATE PCB services provide the flexibility needed to support fast design iterations and high-mix test environments.

What Is a Small Batch ATE PCB?

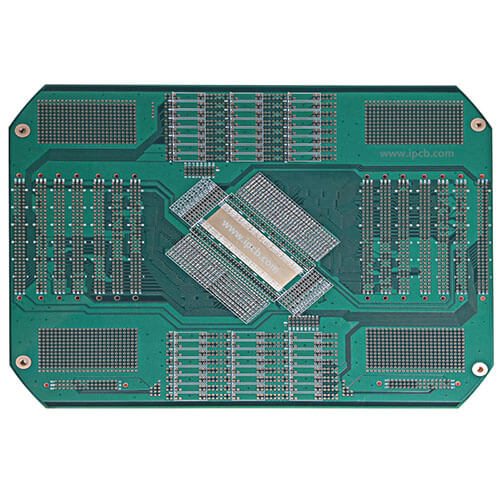

A Small Batch ATE PCB refers to low-volume production of ATE test boards, usually ranging from a few pieces to several dozen units. These PCBs are used as load boards, interface boards, or custom test fixtures within ATE systems.

Small batch ATE PCBs must meet the same electrical and mechanical standards as volume production boards, including controlled impedance, high speed signal integrity, and robust connector interfaces.

Why Small Batch ATE PCB Manufacturing Is Important

Flexible Design Iteration

Small batch manufacturing allows engineers to quickly validate design changes, test different stack-ups, or optimize signal routing without committing to large production quantities.

High Performance Requirements

Even in low volumes, ATE PCBs must support high speed digital, RF, and mixed-signal testing with strict impedance and timing control.

Customization for Test Applications

ATE systems often require application-specific layouts, connector configurations, and DUT interfaces that are not suitable for standard PCB designs.

Key Technical Requirements for Small Batch ATE PCBs

Controlled Impedance

Precise impedance control is essential to ensure accurate high-speed signal transmission and repeatable test results.

High Speed Signal Integrity

Small batch ATE PCBs are designed to minimize signal loss, reflection, and crosstalk in multi-gigabit test environments.

Multilayer and High Density Design

Complex routing and power distribution require multilayer stack-ups and dense interconnections, even in low-volume builds.

Mechanical Reliability

Frequent connector mating and DUT insertion demand robust PCB structures and high-quality surface finishes.

Materials Used in Small Batch ATE PCB Manufacturing

Depending on performance requirements, small batch ATE PCBs may use:

-

High-performance FR-4

-

Rogers RO4350B, RO4835, RO4003

-

Megtron 6 / Megtron 7

-

Taconic high-frequency laminates

-

Hybrid stack-ups for cost and performance optimization

Material selection is tailored to test frequency, data rate, and operating conditions.

Manufacturing Capabilities for Small Batch ATE PCBs

Professional small batch ATE PCB manufacturing includes:

-

Controlled impedance fabrication and verification

-

Multilayer and high layer count PCB production

-

HDI, blind via, and buried via technology

-

Back drilling for improved signal integrity

-

Tight tolerance drilling and registration

These capabilities ensure small batch PCBs perform consistently with production-level designs.

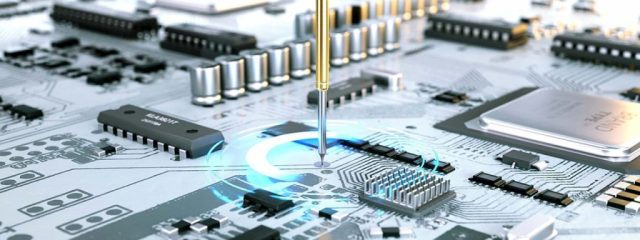

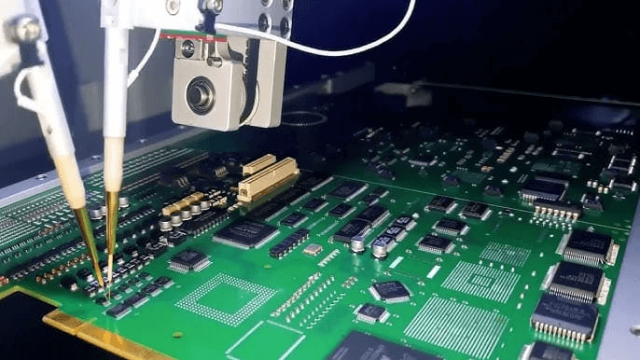

Small Batch ATE PCB Assembly

Assembly is a critical part of small batch ATE PCB delivery:

-

Fine-pitch and high pin count component assembly

-

Precision connector and test socket installation

-

AOI and X-ray inspection

-

Electrical continuity and functional testing

Combining PCB fabrication and assembly under one supplier simplifies project management and improves quality control.

Applications of Small Batch ATE PCBs

Small batch ATE PCBs are widely used in:

-

Semiconductor engineering validation

-

Wafer sort and final test development

-

High speed logic and memory testing

-

RF and mixed-signal IC evaluation

-

Automotive and industrial device testing

In these scenarios, fast turnaround and performance accuracy are critical.

From Small Batch to Volume Production

Small batch ATE PCBs often serve as the foundation for future mass production. Once designs are validated, they can be smoothly transitioned to larger volumes using the same materials, stack-ups, and manufacturing processes.

Working with an experienced small batch ATE PCB supplier ensures continuity from prototype to production.

Conclusion

Small Batch ATE PCB manufacturing provides the flexibility, performance, and reliability required for modern semiconductor testing. By combining controlled impedance design, advanced materials, precision fabrication, and reliable assembly, small batch ATE PCBs support rapid development and accurate test validation.

Choosing a capable supplier for small batch ATE PCB manufacturing helps reduce development risk and accelerate time-to-market.