What Is a Semiconductor Test PCB?

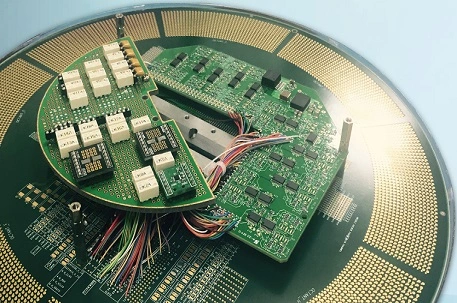

A Semiconductor Test PCB is a printed circuit board specifically designed to test, validate, and measure semiconductor devices under controlled conditions. These PCBs are used in automated test equipment (ATE), burn-in systems, and R&D labs to verify the performance and reliability of ICs before mass production.

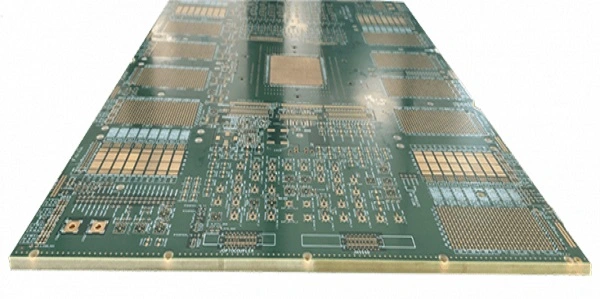

Unlike standard PCBs, Semiconductor Test PCBs are engineered to handle high pin-counts, precise signal routing, and high-speed or high-frequency signals, ensuring accurate measurement results.

Key Design Considerations for Semiconductor Test PCB

Designing a Semiconductor Test PCB requires attention to the following factors:

-

High pin-count routing

Supports complex IC packages such as BGA, QFP, and CSP. -

Controlled impedance traces

Ensures signal integrity for high-speed semiconductors. -

Durable test points

Withstands repeated probing and connection to test equipment. -

Thermal management

Proper copper planes and vias dissipate heat during high-current or burn-in testing. -

Minimal crosstalk and noise

Critical for accurate measurement of analog, digital, and mixed-signal ICs.

Materials and Manufacturing Considerations

Semiconductor Test PCBs often use specialized materials for precision and reliability:

-

High-performance FR-4 laminates

For standard IC testing. -

PTFE or Rogers laminates

For high-frequency or RF semiconductor testing. -

Metal-core or ceramic substrates

For high-current or high-temperature applications.

Manufacturing considerations include:

-

Accurate microvia and via-in-pad technology

Supports high-density IC packages. -

Precise layer registration and lamination

Prevents warpage and ensures dimensional stability. -

Surface finishes

ENIG, hard gold, or immersion silver for reliable probing. -

Electrical and functional testing

Confirms PCB performance before use in test systems.

Advantages of Semiconductor Test PCB

Using a Semiconductor Test PCB provides multiple benefits:

-

High-accuracy IC testing

-

Repeatable and reliable measurement results

-

Support for high-speed, high-frequency devices

-

Early detection of failures in semiconductor devices

-

Improved yield and product quality

These advantages make Semiconductor Test PCBs essential for semiconductor manufacturing and R&D.

Applications of Semiconductor Test PCB

Semiconductor Test PCBs are widely used in:

-

IC and microcontroller functional testing

-

Automated Test Equipment (ATE)

-

Burn-in testing for reliability verification

-

High-frequency RF semiconductor validation

-

Power semiconductor module testing

They are indispensable in semiconductor R&D, QA, and production testing.

Conclusion

A Semiconductor Test PCB is a critical tool for ensuring high-precision testing, reliable measurements, and product quality in semiconductor development and production. With careful design, high-quality materials, and precision manufacturing, Semiconductor Test PCBs provide accurate results, reduce production risks, and improve overall device reliability.

Partnering with an experienced Semiconductor Test PCB manufacturer ensures robust, high-quality boards capable of supporting advanced IC testing and R&D workflows.