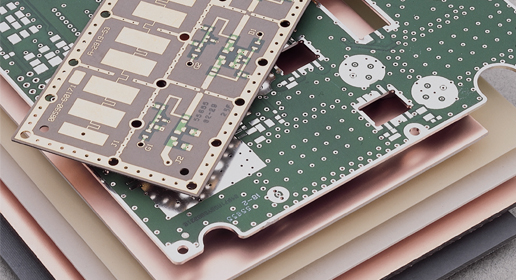

Rogers RT/duroid® 5870 and RT/duroid® 5880 laminates are high-performance PTFE-based composites reinforced with glass microfibers. These laminates are engineered for demanding RF, microwave, and high-frequency applications, offering exceptional electrical, thermal, and mechanical properties. They are widely used in aerospace, defense, commercial communication, and advanced high-frequency systems.

1. General Material Properties

Both RT/duroid 5870 and 5880 laminates exhibit outstanding electrical and thermal stability, with properties tailored for precision high-frequency PCB design:

| Property | RT/duroid 5870 | RT/duroid 5880 |

|---|---|---|

| Dielectric Constant (Dk) | 2.33 ± 0.02 | 2.20 ± 0.02 |

| Loss Tangent (tan δ) | 0.0012 @ 10 GHz | 0.0009 @ 10 GHz |

| Reinforcement Material | Glass Microfibers | Glass Microfibers |

| Thermal Conductivity | 0.2 W/m·K | 0.2 W/m·K |

| Moisture Absorption | <0.02% | <0.02% |

| Operating Temperature Range | -200 to +200°C | -200 to +200°C |

| Density | ~2.1 g/cm³ | ~2.1 g/cm³ |

Highlights:

-

Stable Dielectric Properties: Both laminates maintain consistent Dk values, critical for controlled-impedance circuit designs.

-

Low Dielectric Loss: RT/duroid 5880 offers ultra-low loss for applications requiring minimal signal degradation.

-

Wide Temperature Range: Suitable for extreme environmental conditions, from cryogenic to high-temperature operations.

2. Mechanical Properties

RT/duroid 5870 and 5880 laminates exhibit strong mechanical stability and durability:

| Property | RT/duroid 5870 | RT/duroid 5880 |

|---|---|---|

| Peel Strength | 0.7 N/mm | 0.7 N/mm |

| Tensile Modulus | 1.4 GPa | 1.4 GPa |

| Dimensional Stability | ~0.05 mm/m | ~0.05 mm/m |

| Coefficient of Thermal Expansion (CTE) | ~24 ppm/°C (X, Y) | ~24 ppm/°C (X, Y) |

Highlights:

-

Dimensional Stability: Minimizes warpage during fabrication and operation.

-

Thermal Expansion Control: Uniform expansion in X and Y directions ensures reliable multilayer stackup.

-

Peel Strength: Strong adhesion between copper foil and laminate ensures reliability in demanding PCB assemblies.

3. Electrical Properties

| Property | RT/duroid 5870 | RT/duroid 5880 |

|---|---|---|

| Dielectric Breakdown Voltage | >500 V/mil | >500 V/mil |

| Surface Resistivity | 10^9 Ω/sq | 10^9 Ω/sq |

| Volume Resistivity | 10^10 Ω·cm | 10^10 Ω·cm |

Highlights:

-

High Voltage Tolerance: Suitable for high-power RF and microwave circuits.

-

Excellent Insulation: High surface and volume resistivity provide low leakage and stable performance.

4. Applications

RT/duroid 5870:

-

RF and microwave circuits for commercial, aerospace, and defense sectors.

-

Applications that require low dielectric loss and stable performance across frequency and temperature.

RT/duroid 5880:

-

Ultra-low loss RF and microwave systems.

-

High-frequency antennas, radars, and low-loss transmission lines.

-

Ideal for precision high-frequency designs requiring minimal signal attenuation.

5. Key Feature Comparison

| Feature | RT/duroid 5870 | RT/duroid 5880 |

|---|---|---|

| Loss Performance | Moderate | Ultra-Low |

| Cost | Moderate | Higher |

| Suitability for High Frequencies | Excellent | Exceptional |

Interpretation:

-

5870 offers a cost-effective solution with excellent high-frequency performance.

-

5880 provides the lowest electrical loss, ideal for ultra-high-performance RF and microwave applications where signal integrity is critical.

6. Recommendations for PCB Design and Fabrication

-

Controlled Impedance Design: Use stable Dk values for precise line widths in striplines, microstrips, or differential pairs.

-

Post-Etch Stress Relief: Consider baking the laminate after etching to relieve residual mechanical stresses and maintain dimensional stability.

-

Copper Adhesion: Follow manufacturer guidelines to ensure strong bonding and avoid delamination during soldering or reflow.

-

Thermal Management: Maintain temperature limits during processing to prevent warpage or degradation of electrical performance.

-

Moisture Control: RT/duroid laminates’ low moisture absorption minimizes changes in Dk and dielectric loss in humid environments.

7. Conclusion

RT/duroid® 5870 and 5880 laminates are industry-standard materials for high-frequency PCB applications, combining stable dielectric properties, low loss, and superior mechanical performance.

-

5870: Balanced performance and cost for high-frequency designs.

-

5880: Ultra-low loss material for critical RF, microwave, and broadband systems.

Both laminates support reliable, repeatable, and high-performance PCB designs across aerospace, defense, commercial communication, and advanced electronics applications.

Fabrication Guidelines RT-duroid 5870-5880 High Frequency Circuit Materials

How to Avoid Creep on Board Assemblies

After Etch Stress Relief in RT-duroid Microwave Laminates

Safety Notes on Using PTFE Composite Material

Line Widths for Various Characteristic Impedance of Center Stripline Devices in RT duroid Laminates

Temperature Rise Estimations in Rogers High Frequency Circuit Boards Carrying Direct or RF Current

The Advantage of Nearly Isotropic Dielectric Constant of RT-duroid 5870-5880 Glass Microfiber PTFE

RT-duroid PTFE-Based Composite Meets Flammability Requirements for Oxygen Environments

A Study of Solder Temperature Effect of Copper Foil Adhesion to RT-duroid 5870 Material