The RO4500™ series antenna-grade laminates are specifically designed to deliver high electrical performance, thermal reliability, and cost-effective manufacturability for high-frequency applications. Ideal for antennas, wireless communication systems, and IoT devices, these laminates simplify design and assembly while maintaining signal integrity and durability.

Key Features

-

Stable Dielectric Properties:

Uniform dielectric constant (Dk) across a broad frequency range ensures minimal signal distortion. Low dissipation factor (Df) reduces signal loss, enhancing overall performance. -

Thermal Reliability:

High thermal conductivity and excellent dimensional stability allow efficient heat management, reducing thermal-induced design issues. -

Cost Efficiency:

Optimized for price-sensitive applications, offering high performance without excessive costs. -

Ease of Processing:

Fully compatible with FR-4 PCB manufacturing processes, supporting lead-free soldering and modern assembly techniques.

Material Properties

| Property | RO4533™ | RO4535™ |

|---|---|---|

| Dielectric Constant (Dk) | 3.3 ± 0.05 | 3.5 ± 0.05 |

| Dissipation Factor (Df) | 0.0021 @ 10 GHz | 0.0027 @ 10 GHz |

| Thermal Conductivity | 0.5 W/m·K | 0.5 W/m·K |

| Moisture Absorption | <0.1% | <0.1% |

| Thermal Decomposition (Td) | 390°C | 390°C |

| Glass Transition Temperature (Tg) | >280°C | >280°C |

| Peel Strength | ≥7 lb/in | ≥7 lb/in |

Applications

-

Patch antennas for GPS and communication systems

-

Automotive radar, telematics, and ADAS sensors

-

Base station and cellular antennas

-

IoT and wireless sensor devices

-

High-frequency RF and microwave circuits

Processing Guidelines

-

Drilling:

Use carbide drill bits for precise holes. Spindle speed: 150,000–200,000 RPM; feed rate: 2–3 mil/rev. -

Etching:

Compatible with standard copper etching processes. Maintain accurate line width and spacing control for high-frequency designs. -

Lamination:

Use standard FR-4 lamination procedures. Recommended temperature: 425–450°F (220–230°C); pressure: 200–400 psi. -

Solder Mask & Finishes:

Apply solder masks compatible with high-frequency laminates. Suitable finishes include ENIG, immersion silver, tin, and OSP.

Performance Highlights

-

Low Loss: Ensures minimal signal degradation for high-efficiency antennas.

-

Thermal Management: Supports high-power designs and enhances system reliability.

-

Environmental Stability: Low moisture absorption guarantees consistent performance in humid conditions.

Benefits

-

Cost Savings: Optimized for large-scale, price-sensitive antenna applications.

-

Design Flexibility: Stable dielectric properties simplify impedance matching and reduce design iterations.

-

Durability: High thermal and mechanical performance ensures long-lasting reliability in demanding environments.

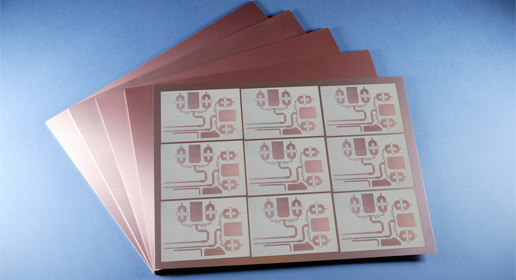

Available Configurations

-

Thickness Options: Multiple thicknesses to meet application-specific needs.

-

Copper Cladding: Offered with rolled or electrolytic copper in various thicknesses.

Summary:

RO4500™ series laminates combine excellent electrical and thermal properties with ease of processing and cost efficiency, making them a preferred choice for high-frequency antennas, RF systems, and wireless communication designs. Their stability and reliability ensure optimal performance across a wide range of high-frequency PCB applications.