1. Introduction

As radar and wireless communication move into the 24GHz spectrum, selecting the right high-frequency PCB material becomes one of the most critical design decisions.

Among the top contenders, Rogers RO3003 and RO4350B stand out for their reliable electrical performance and widespread industrial use.

At KKPCB, our engineering team has extensive experience fabricating both RO3003 and RO4350B-based multilayer PCBs for automotive radar, 5G front-end modules, and RF filter systems.

This article provides a professional comparison between the two — from dielectric behavior to manufacturing implications — helping engineers and sourcing managers choose the right material for their next 24GHz project.

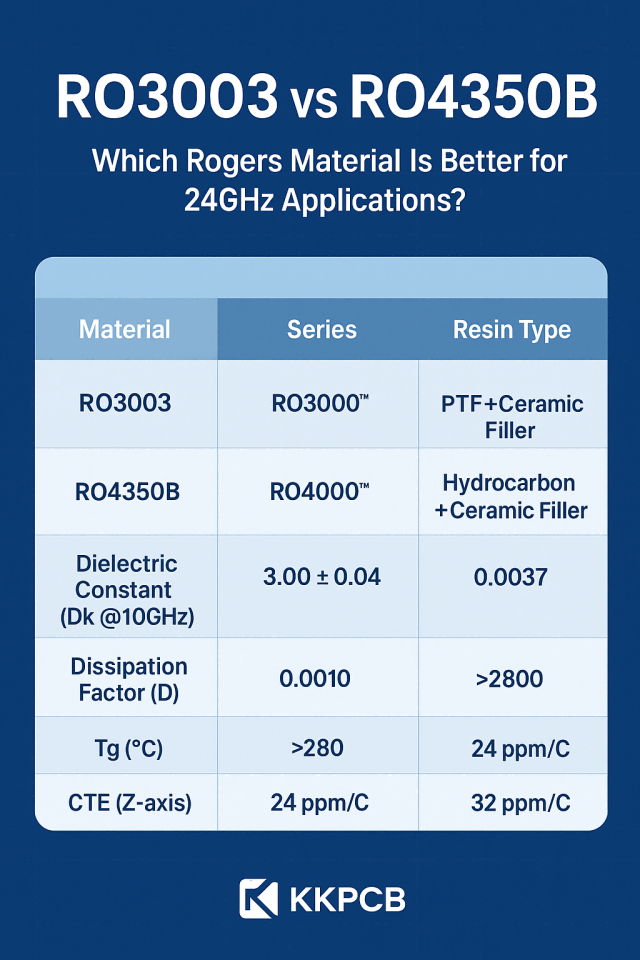

2. Material Overview

Both materials exhibit excellent high-frequency stability.

However, RO3003’s PTFE-based formulation provides lower dielectric loss and tighter impedance control — ideal for radar or mmWave systems requiring ultra-stable signals.

Meanwhile, RO4350B is optimized for cost-effective mass production with standard FR4-compatible processes.

3. Electrical Performance at 24GHz

At 24GHz, performance margins are tight — every tenth of a decibel counts.

(1) Dielectric Constant (Dk)

A lower and more stable Dk means more predictable signal integrity and controlled impedance — crucial for radar phase alignment.

(2)Dissipation Factor (Df)

This difference can cause 0.2–0.3dB additional signal loss per inch at 24GHz.

For short paths, it’s acceptable — but for antenna arrays, filters, or power dividers, RO3003 provides superior consistency.

4. Processing and Manufacturability

While RO3003 provides exceptional electrical performance, its PTFE base requires tighter process control — including plasma treatment and vacuum lamination.

RO4350B, however, integrates seamlessly into standard FR4 lines, significantly lowering production costs.

At KKPCB, we’ve optimized both processes:

-

RO3003: Dedicated high-frequency vacuum lamination and controlled impedance routing lines.

-

RO4350B: Hybrid stack-up integration with FR4 for mixed-signal boards (RF + digital).

Our one-stop engineering support helps customers balance cost, yield, and performance, especially in multi-frequency system designs.

5. Typical Applications

KKPCB has successfully supported clients in automotive radar, satellite communication, and 5G antenna module production using both materials, providing DFM optimization, panel utilization planning, and signal integrity validation during prototype and mass production stages.

6. Cost and Reliability Considerations

- While RO3003 delivers the best performance, its processing cost is about 30–40% higher.

For clients targeting high-performance radar or precision sensing, KKPCB often recommends RO3003.

For mixed-frequency modules or mass-market IoT devices, RO4350B provides a great middle ground. - KKPCB’s hybrid PCB stack-up service allows designers to combine RO4350B and FR4 in one board — achieving both cost efficiency and RF reliability.

7. Conclusion

For 24GHz and higher-frequency applications, RO3003 outperforms in dielectric stability and low loss — ideal for radar, 5G, and precision RF modules.

RO4350B, on the other hand, offers excellent manufacturability and cost efficiency, making it suitable for mass production.

At KKPCB, we specialize in high-frequency PCB manufacturing, offering:

-

RO3003 / RO4350B / Taconic / PTFE PCB production

-

Hybrid multilayer lamination (FR4 + RF materials)

-

Controlled impedance & signal integrity design assistance

-

Rapid prototype to volume manufacturing under one roof

Whether you’re developing radar sensors, 5G modules, or RF front-end systems, our engineers can help you choose the right substrate and achieve the best balance between performance, cost, and manufacturability.