Submitting a clear and complete PCB price request is the most effective way to receive an accurate quotation, reduce communication time, and speed up PCB production. Whether you are ordering PCB prototypes, small batch runs, or mass production, the quality of your price request directly affects cost, lead time, and manufacturing feasibility.

This guide explains what information is required in a PCB price request and how to optimize it for faster and more reliable quotations.

What Is a PCB Price Request?

A PCB price request is a formal inquiry sent to a PCB manufacturer to obtain pricing based on your design, quantity, and delivery requirements. A professional quotation usually includes:

-

Unit price

-

Tooling or setup cost

-

Lead time

-

Manufacturing options and notes

Accurate PCB pricing depends on how complete and precise your request is.

Essential Information for a PCB Price Request

To receive a fast and accurate PCB quotation, your PCB price request should include the following details:

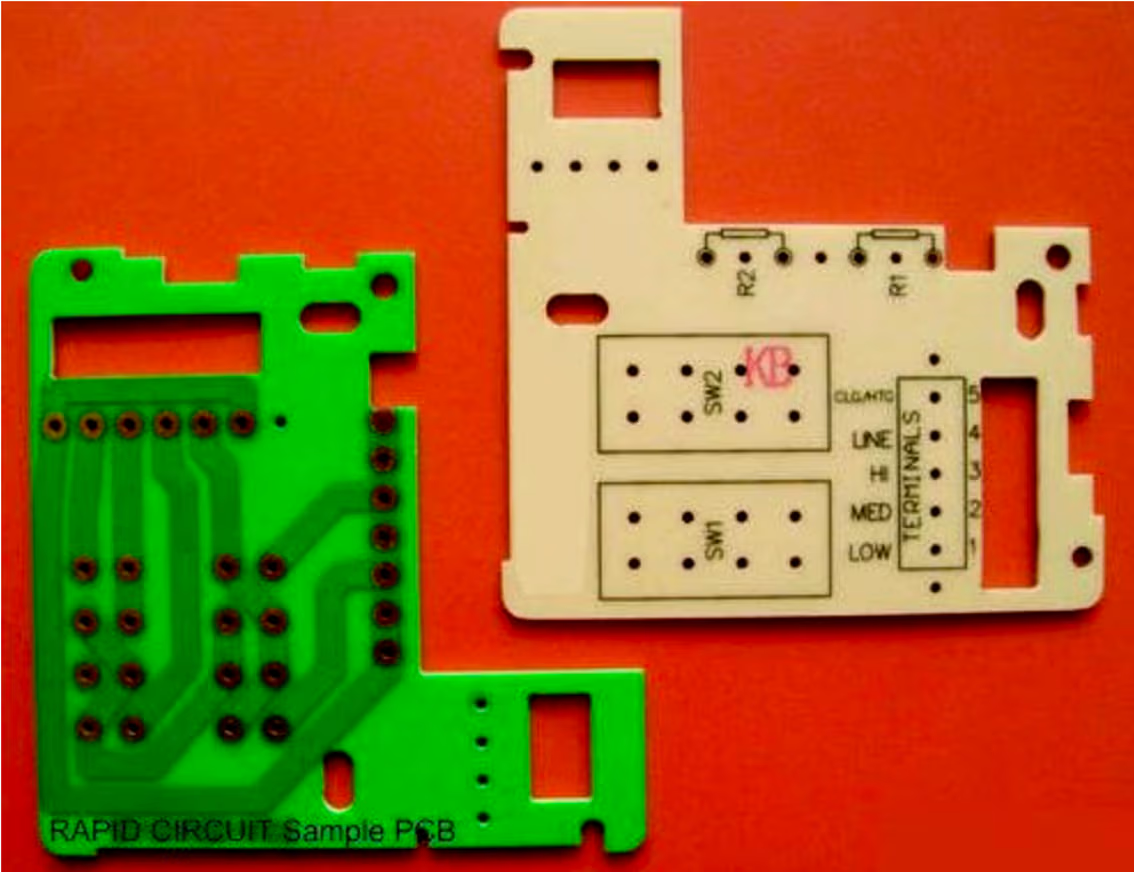

1. Basic PCB Specifications

-

Board size and outline

-

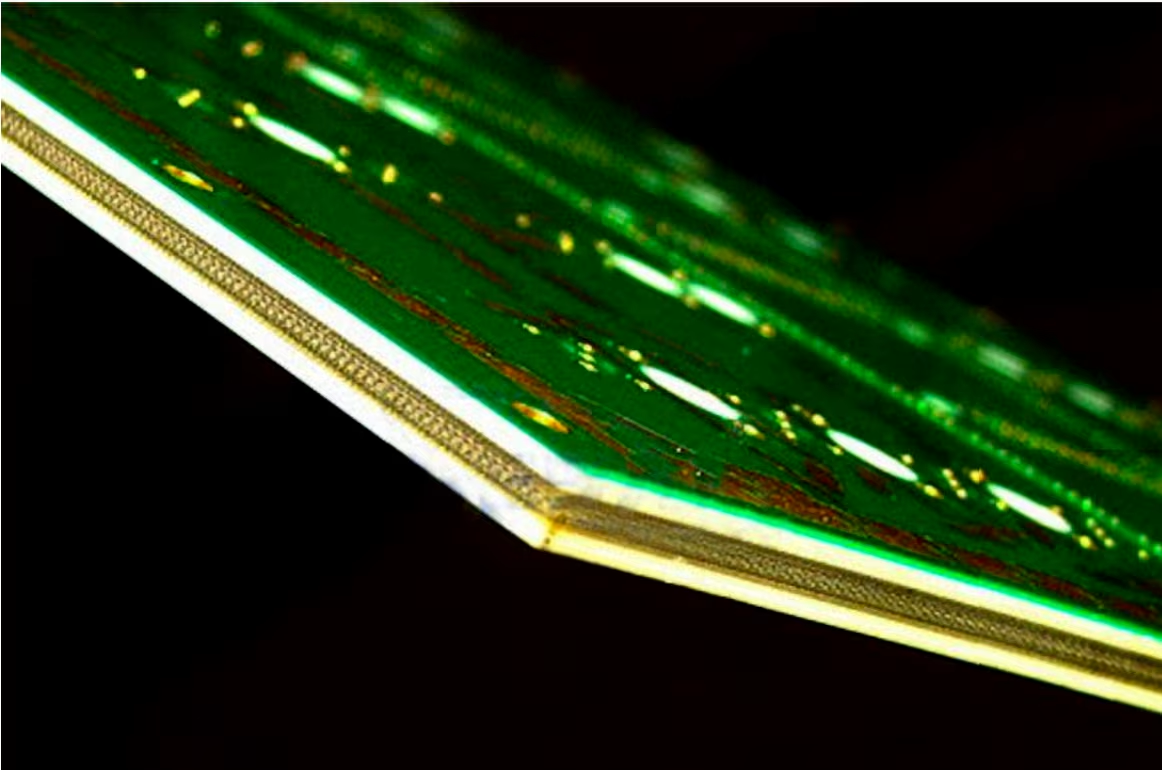

Number of layers

-

Base material (FR-4, Rogers, PTFE, hybrid stackup)

-

Board thickness

-

Copper thickness (inner and outer layers)

These parameters directly influence manufacturing cost.

2. Design Files

-

Gerber files or ODB++ data

-

Drill files

-

Stack-up details (if available)

-

Controlled impedance requirements

Providing complete design files minimizes quotation errors and delays.

3. Order Quantity and Production Type

-

Prototype, small batch, or mass production

-

Target order quantity

-

Estimated annual volume (if applicable)

Volume has a significant impact on PCB unit price.

4. Special Manufacturing Requirements

-

Surface finish (ENIG, HASL, OSP, Immersion Silver, etc.)

-

Impedance control tolerance

-

Via types (blind, buried, microvia)

-

Electrical or RF testing requirements

Special processes may increase cost and lead time.

5. Lead Time and Delivery Information

-

Standard or urgent lead time

-

Target delivery date

-

Shipping destination

Clear delivery expectations help manufacturers propose the best solution.

Why a Complete PCB Price Request Matters

A detailed PCB price request helps manufacturers:

-

Respond faster with accurate quotations

-

Avoid repeated clarification emails

-

Optimize manufacturing methods

-

Suggest cost-saving alternatives

For buyers, this means better pricing, shorter lead times, and smoother production.

From PCB Price Request to Production

After your PCB price request is confirmed, a reliable manufacturer can provide:

-

DFM (Design for Manufacturability) feedback

-

Prototype and small batch production

-

Stable scaling to mass production

A strong supplier relationship ensures long-term cost control and quality consistency.

Conclusion

A well-prepared PCB price request is essential for obtaining accurate pricing, competitive cost, and reliable delivery. By providing complete technical specifications, design files, and clear quantity requirements, you can significantly improve quotation speed and accuracy.

Partnering with an experienced PCB manufacturer ensures transparent pricing, professional support, and dependable production from quotation to delivery.