Choosing PCB factory direct manufacturing has become the preferred sourcing model for global electronics companies seeking lower cost, faster response, and higher quality control. By working directly with a PCB factory, customers eliminate intermediaries and gain full transparency over pricing, lead time, and manufacturing processes.

PCB factory direct sourcing is ideal for PCB prototypes, small batch orders, and large-scale production, especially for high-frequency, high-speed, and complex PCB designs.

What Does PCB Factory Direct Mean?

PCB factory direct means purchasing PCBs directly from the manufacturing factory rather than through traders, agents, or resellers. In a factory direct model, customers communicate directly with the engineering, production, and quality teams responsible for PCB fabrication.

This direct relationship ensures clearer communication, faster problem-solving, and more competitive pricing.

Key Advantages of PCB Factory Direct Manufacturing

1. Lower PCB Cost with Transparent Pricing

One of the biggest benefits of PCB factory direct sourcing is cost reduction:

-

No middleman markup

-

Direct factory pricing

-

Clear cost breakdown and optimization options

Factory direct PCB pricing is especially advantageous for long-term and volume projects.

2. Faster Communication and Engineering Support

With PCB factory direct manufacturing, customers gain:

-

Direct access to PCB engineers

-

Faster DFM (Design for Manufacturability) feedback

-

Immediate response to technical questions

This shortens development cycles and reduces costly design errors.

3. Better Quality Control at the Source

PCB factory direct production enables:

-

In-house quality control at every manufacturing stage

-

Full process traceability

-

Immediate corrective action when issues arise

Direct oversight ensures consistent PCB quality and high production yield.

4. Flexible Production from Prototype to Mass Production

A professional PCB factory direct manufacturer supports:

-

Quick-turn PCB prototypes

-

Small batch PCB manufacturing

-

Scalable mass production

This flexibility allows smooth transition from R&D to volume manufacturing.

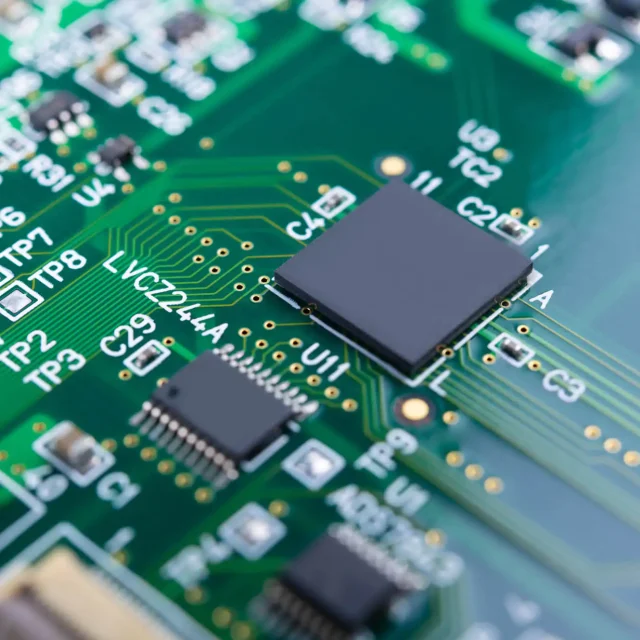

PCB Factory Direct Manufacturing Capabilities

A qualified PCB factory direct supplier typically offers:

-

Multilayer PCB fabrication

-

High-frequency and high-speed PCB manufacturing

-

Controlled impedance PCB production

-

Advanced surface finishes (ENIG, OSP, Immersion Silver, etc.)

-

Electrical testing and reliability inspection

These capabilities ensure PCB performance and manufacturing stability.

Applications Suitable for PCB Factory Direct Sourcing

PCB factory direct manufacturing is widely used in:

-

Consumer electronics

-

Industrial control systems

-

Automotive electronics

-

RF and high-frequency applications

-

Communication and networking equipment

These applications benefit from direct cost control and reliable supply.

How to Choose a Reliable PCB Factory Direct Partner

When selecting a PCB factory direct manufacturer, evaluate:

-

Manufacturing capacity and equipment

-

Experience with complex and high-frequency PCBs

-

Quality management and testing capability

-

Communication efficiency and technical support

-

Lead time reliability and scalability

A strong factory direct partner ensures long-term success.

Conclusion

PCB factory direct manufacturing offers clear advantages in cost efficiency, communication speed, and quality control. By working directly with a professional PCB factory, customers gain transparent pricing, faster engineering support, and reliable production from prototype to mass production.

Choosing an experienced PCB factory direct manufacturer ensures your PCB projects are delivered with consistent quality, competitive cost, and dependable lead time.