In today’s global electronics supply chain, many companies are choosing PCB factory direct sourcing to reduce costs, improve communication, and ensure consistent manufacturing quality. Working directly with a PCB factory eliminates unnecessary intermediaries and gives customers greater control over pricing, lead time, and production transparency.

This article explains what PCB factory direct means, why it matters, and how it benefits engineers and purchasing teams worldwide.

What Does PCB Factory Direct Mean?

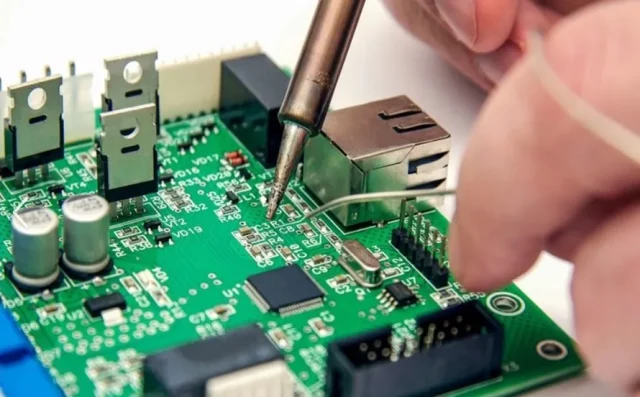

PCB factory direct refers to purchasing PCBs directly from the manufacturing factory rather than through traders, agents, or third-party distributors. With factory direct sourcing, customers communicate directly with the production team responsible for fabrication and quality control.

This model is widely used for PCB prototypes, small batch orders, and mass production.

Key Advantages of PCB Factory Direct Manufacturing

1. Lower Manufacturing Cost

Factory direct PCB sourcing eliminates middleman markups, resulting in:

-

More competitive PCB pricing

-

Transparent cost structure

-

Better cost optimization options

This is especially beneficial for high-volume or long-term projects.

2. Faster Communication and Engineering Support

Direct access to the PCB factory allows:

-

Faster response to technical questions

-

Direct DFM (Design for Manufacturability) feedback

-

Quicker issue resolution during production

Improved communication helps reduce delays and design misunderstandings.

3. Better Quality Control

With PCB factory direct manufacturing:

-

Quality standards are managed in-house

-

Production processes are fully traceable

-

Issues can be addressed immediately at the source

This leads to more consistent and reliable PCB quality.

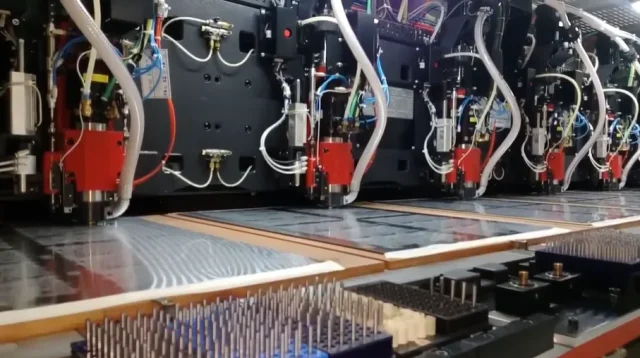

4. Flexible Production from Prototype to Mass Production

PCB factories typically support:

-

Quick-turn PCB prototyping

-

Small batch PCB manufacturing

-

Scalable mass production

Factory direct partners can smoothly support product development through all production stages.

Applications Suitable for PCB Factory Direct Sourcing

PCB factory direct manufacturing is widely used in:

-

Consumer electronics

-

Industrial control systems

-

Automotive electronics

-

High-speed and RF PCB projects

-

Medical and communication devices

These applications benefit from cost efficiency, reliability, and stable supply.

How to Choose a Reliable PCB Factory Direct Partner

When selecting a PCB factory direct supplier, consider:

-

Manufacturing capability and equipment

-

Material options (FR-4, Rogers, PTFE, hybrid stackups)

-

Impedance control and testing capability

-

Quality certifications and experience

-

Communication and technical support

A qualified factory direct PCB manufacturer ensures long-term cooperation and consistent results.

Conclusion

Choosing PCB factory direct sourcing provides clear advantages in cost, communication, and quality control. By working directly with an experienced PCB factory, customers can achieve faster turnaround, competitive pricing, and reliable manufacturing performance.

Partnering with a trusted PCB factory direct manufacturer ensures your PCB projects are produced efficiently, accurately, and cost-effectively from prototype to mass production.