As 5G RF front-end modules push into sub-6 GHz and mmWave bands, PCB materials must deliver extreme electrical precision, low-loss propagation, and predictable thermal behavior. TLY-5 PCB laminates, based on PTFE composites engineered with ultra-low dielectric constant (Dk ≈ 2.17) and low dissipation factor (Df ≈ 0.0009), have emerged as one of the most reliable high-frequency materials for achieving stable RF performance under wide temperature and power conditions in 5G transceiver architectures.

5G front-end modules—particularly LNA blocks, PA stages, beamforming IC interconnects, RF switches, and antenna feed structures—demand high-frequency PCB materials that maintain consistent impedance and minimal dielectric dispersion. TLY-5 PCB laminates meet these requirements through their uniform Dk distribution and exceptional low-loss characteristics. This ensures that RF signal paths within microstrip, grounded coplanar waveguide (GCPW), and hybrid stripline structures sustain clean, low-phase-noise propagation up to mmWave frequencies.

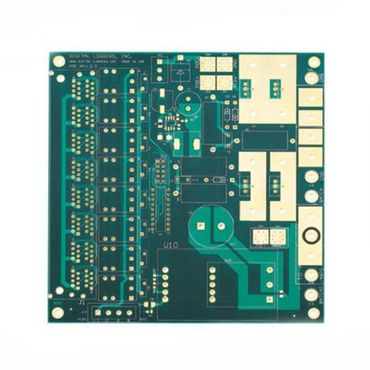

Signal integrity becomes especially critical as front-end routing density increases. High-Q filtering networks, baluns, couplers, and antenna feed arrays rely on tight impedance control, and TLY-5 PCB materials provide the electromagnetic stability needed to minimize transmission and reflection losses. The laminate’s PTFE-based composition promotes uniform electric-field distribution across the substrate, reducing the risk of higher-order mode excitation and preventing parasitic coupling in complex multilayer RF layouts.

Thermal performance is another decisive factor for 5G RF front-end reliability. Power amplifiers and hybrid beamforming elements generate significant heat, creating thermal gradients that can cause Dk drift and phase instability in conventional laminates. TLY-5 PCB materials counter these issues with an exceptionally low thermal coefficient of dielectric constant (TCDk), allowing phase linearity and impedance characteristics to remain stable—even under continuous high-power operation. This stability greatly enhances link performance, reduces system-level EVM degradation, and maintains array-level beam coherence.

The mechanical characteristics of TLY-5 PCB laminates also support precision multilayer stackup construction for 5G modules. Their stable PTFE-glass matrix provides excellent copper adhesion, low moisture absorption, and reliable dimensional stability, minimizing routing shifts and maintaining consistent RF transitions between layers. These properties improve insertion loss performance, increase power-handling capability, and enhance long-term reliability for outdoor and industrial 5G deployments.

In advanced 5G architectures—such as massive MIMO arrays, phased-array front-ends, mmWave backhaul radios, and edge AI connectivity nodes—TLY-5 PCB materials deliver the high-frequency signal integrity, thermal stability, and manufacturing consistency needed to maintain system linearity and spectral efficiency. As networks continue scaling toward 6G-level bandwidth and carrier aggregation demands, TLY-5 remains a dependable foundation for high-performance RF module design.